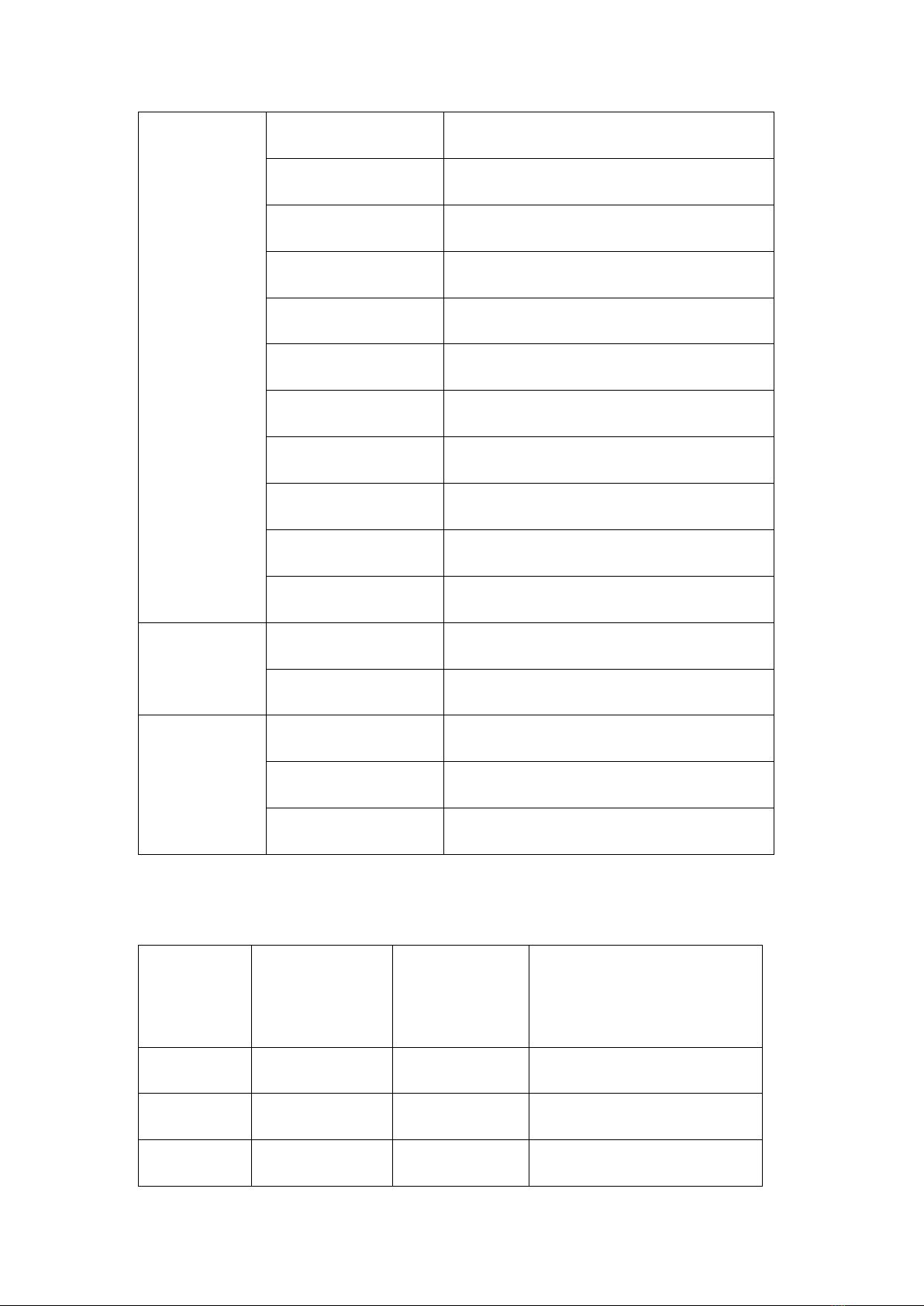

1.4 -inch LCD color screen, can set the channel mode (standard

model, extended mode), horizontal vertical inversion, screen

reversible, signal hint, switchable in both Chinese and English,

automatic screen turn off / long last for display power on, display the

channel number, source temperature, fan speed, record the power on

time, power on times, fault prosecution, manual control channel data

memory, the software version information, restore factory Settings,

the scanning and the effect correction result.

LED opening mode: supports instant blackout f and light on

Effect parameters:

Color wheel: 11 colors + CTO +1 CTB + white, semi-color effect

+bi-direction flow effect.

Fixed gobo: 9 gobos +2 beam holes of different sizes + white,shaking

+ bi-direction flow effect.

Prisms: 8-facet prisms, 16-facet prisms, available for overlapping into

24-facet prisms, independent bi-direction rotation.

Six-color wheel : 1, work with a prism can present the effect of

six-color prism.

Beam Angle: 0.85 degrees.

Frost: linear soft light.

Scanning: use three-phase motor, Pan 540°/1.8 seconds, tilt 270°

/0.9 seconds, 8-16 bit scanning, using photoelectric reset with

automatic error correction function.

Working parameters:

Operating voltage: AC100V~240V, 50/60hz