TABLE OF CONTENTS

SAFETY...........................................................................................................................................01

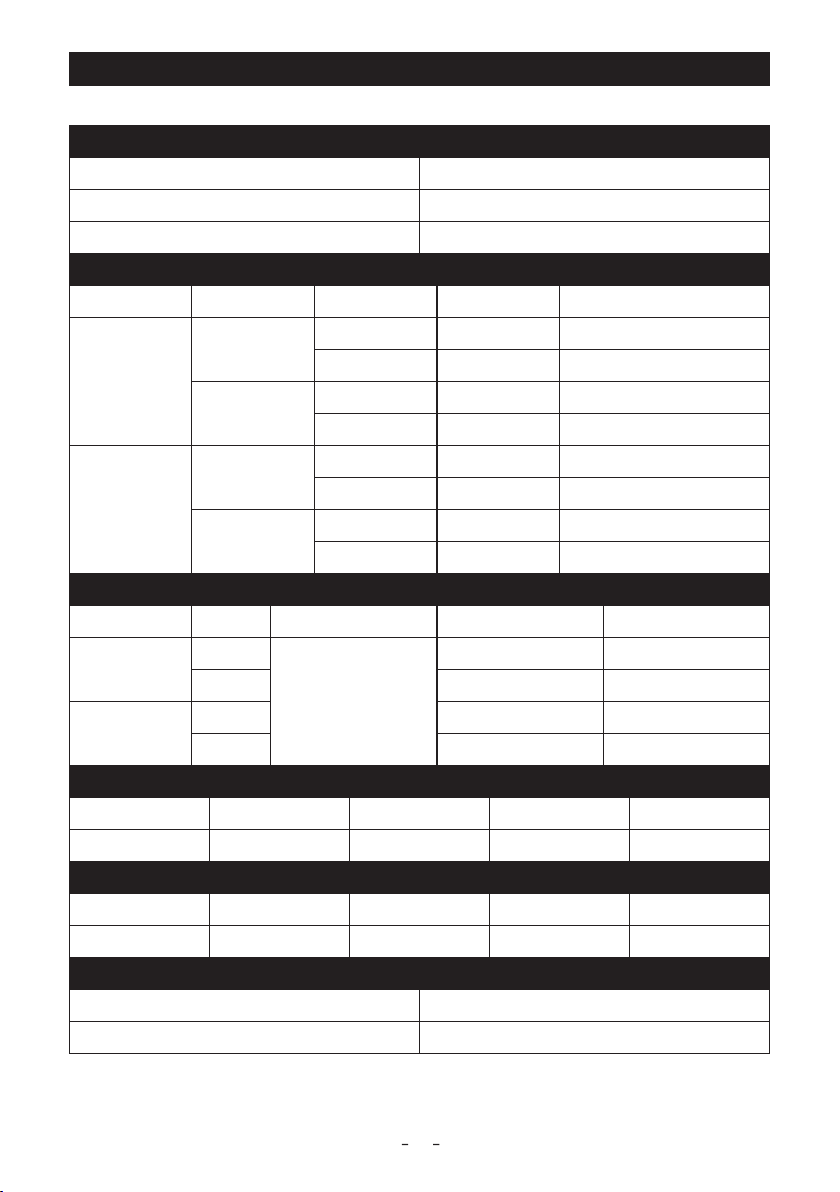

INSTALLATION...............................................................................................................................05

TECHNICAL SPECIFICATIONS ..................................................................................................05

INCLUDED COMPONENTS ........................................................................................................06

SAFETY PRECAUTIONS .............................................................................................................07

SUITABLE LOCATION .................................................................................................................07

GRINDING ....................................................................................................................................07

STACKING ...................................................................................................................................07

LIFTING ........................................................................................................................................07

TILTING ........................................................................................................................................07

ENCLOSURE RATING .................................................................................................................07

MACHINE GROUNDING ..............................................................................................................07

INPUT CONNECTION ..................................................................................................................08

INPUT FUSE AND SUPPLY WIRE ..............................................................................................08

INPUT VOLTAGE .........................................................................................................................08

OUTPUT CONNECTIONS ...........................................................................................................08

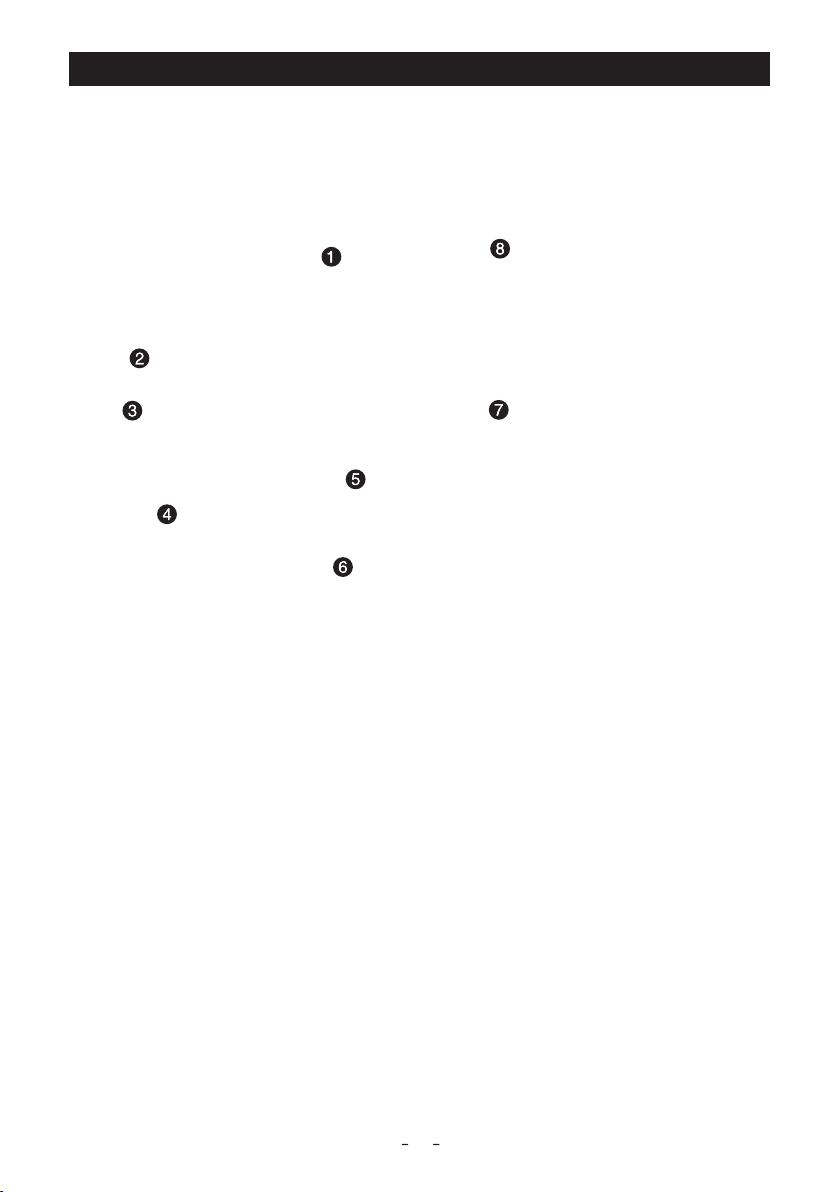

CONNECTION DIAGRAMS FOR THE TIG-225P ........................................................................09

OPERATION....................................................................................................................................10

CASE FRONT & BACK CONTROLS ...........................................................................................10

USER INTERFACE CONTROLS .................................................................................................11

PROCESS, OUTPUT CONTROL .................................................................................................11

2-STEP FUNCTIONALITY, OUTPUT ON ....................................................................................12

4-STEP FUNCTIONALITY, OUTPUT ON ....................................................................................12

SEQUENCER FUNCTIONS, PULSE SEQUENCER FUNCTIONS .............................................13

SETUP MENU STICK WELDING (SMAW) ..................................................................................14

SAFETY PRECAUTIONS..............................................................................................................15

ROUTINE AND PERIODIC ENGINE MAINTENANCE.................................................................15

THERMOSTATIC PROTECTION..................................................................................................15

TROUBLESHOOTING....................................................................................................................16

SAFETY PRECAUTIONS .............................................................................................................16

HOW TO USE TROUBLESHOOTING GUIDE .............................................................................16

TROUBLESHOOTING GUIDE .....................................................................................................16

WIRING DIAGRAM.........................................................................................................................19