II. Operation Instructions:

1. Fill the fructose reservoir before you power on the machine. If the fructose level

becomes too low during operation the machine will emit 5 beeps and the indicator

light will begin to flash. Please refill with fructose immediately to avoid

malfunction.

2. If uninterrupted dispensing is needed, long press the “Continue/Stop” key (6

seconds) until 5 beeps are heard and then release to start dispensing. To stop,

press “Continue/ Stop” once briefly.

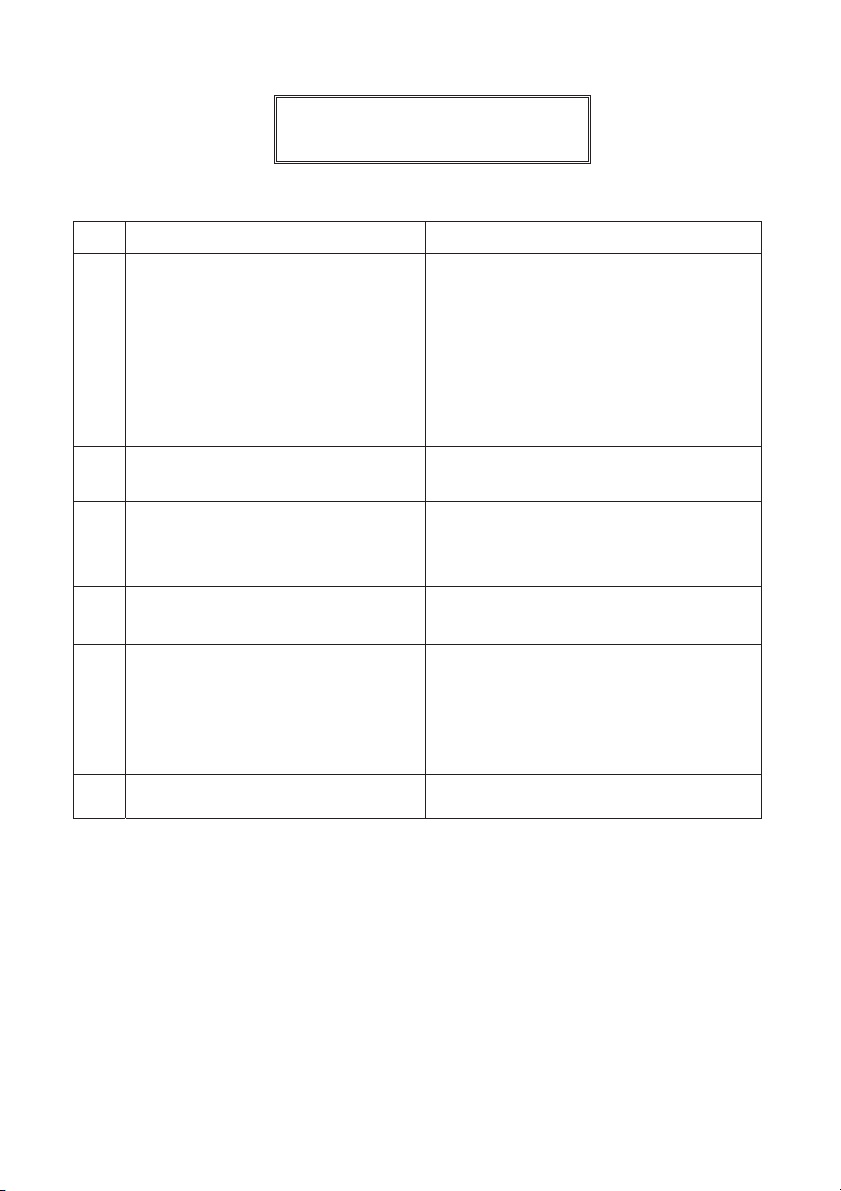

3. For single unit flow rate settings: press the “Setting” key Æselect the key set to

be defined ÆÆwhen settings are all done

Æpress the “Save” key again to finish.

III. Notes:

1. This machine can be adjusted to suit the viscosity of the fructose.

2. Before using the first time, clean the interior of the reservoir with warm water

(60°C). Fill with fructose after cleaning and drying with absorbent paper or cloth.

After filling press the “Continue” key to release about 500ml to drive out any air or

water that remains in the system.

3. Filling the reservoir with fructose should be done slowly to avoid the generation of

air bubbles that can influence the output accuracy.

4. It is recommended that the output nozzle be cleaned regularly (at least once per

month) to ensure accuracy of the dispenser. Cleaning may be done more

frequently if necessary.

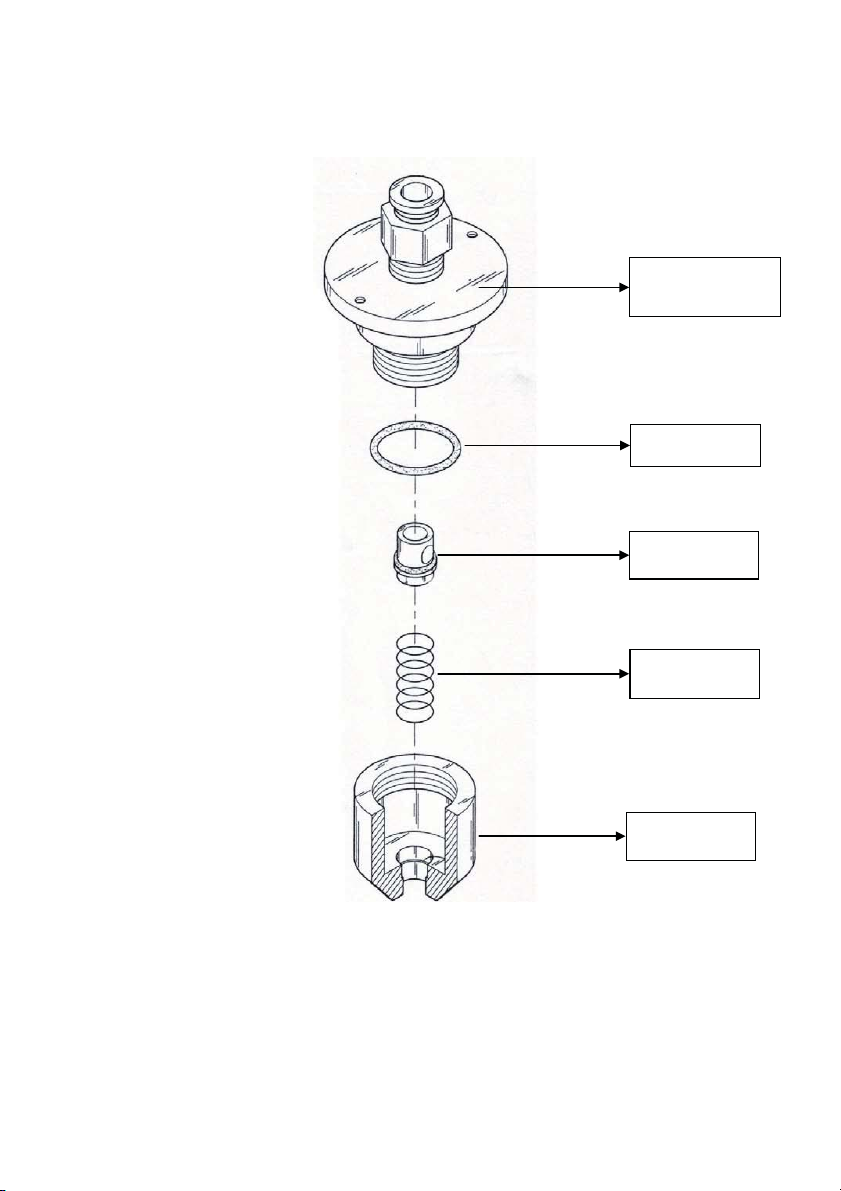

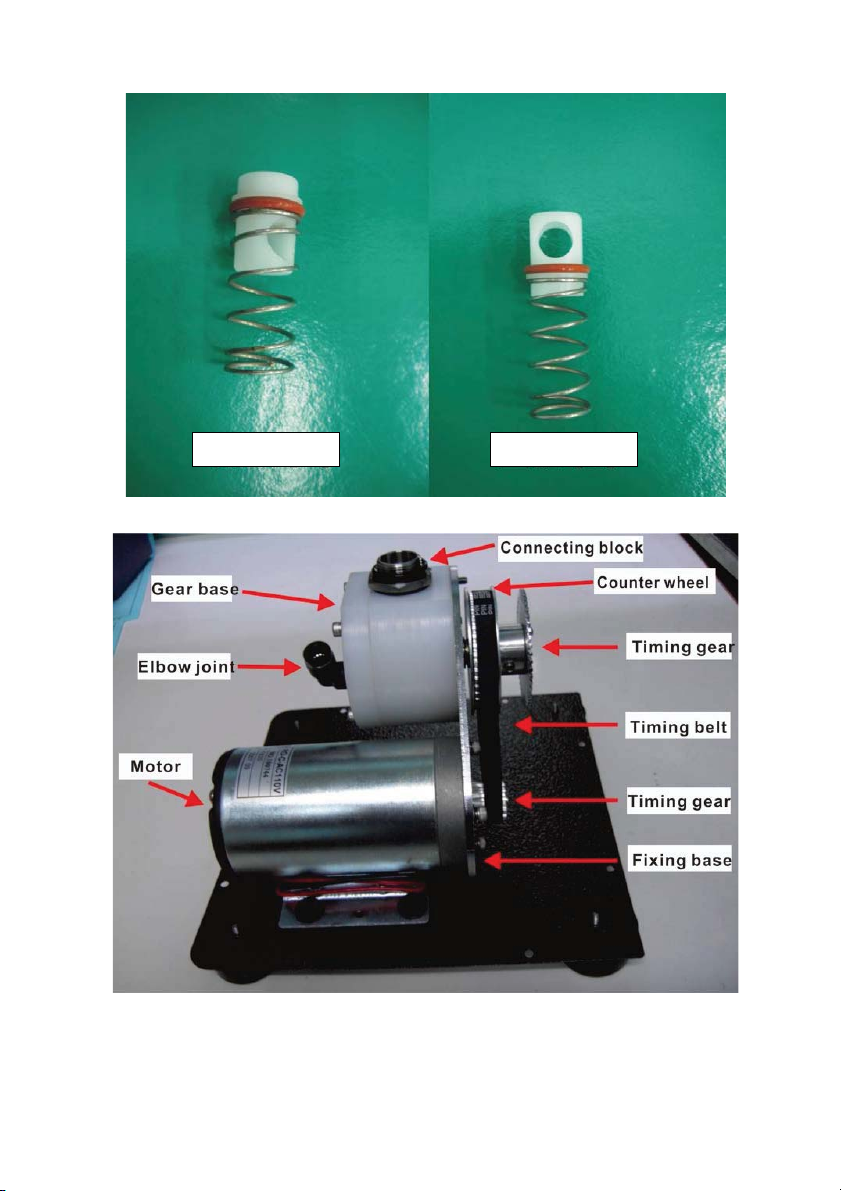

5. Fructose output nozzle cleaning procedures: (as in Attachment 1, on the rear side

of this manual).

(1) Rotate clockwise to remove fructose nozzle for cleaning.

(2) After cleaning, follow the procedure in Attachment 1 Component Detailed

Drawings to reinstall and tighten it counterclockwise.

6. Using hot water for cleaning is strictly prohibited.

-2-