12

Using this machine, the following basic measures to abide by, in order to avoid

electric shock or cause harm to human body.

1. In order to ensure the personal safety, the machine work has been

completed, please close the total power switch to the machine, not use

for a long time please unplug the power cord!

2. You must use the original approved or recommended by parts, otherwise will

lead to serious consequences.

3. Machine failure must be by professionals or the company designated

personnel for repair.

4. This product use three-wire grounding plug, grounding must be inserted into

the three hole socket, don’t change the plug or make with three head off

ground adapter and make bad earth.

5. Please make sure that in the safe state, the machine open, and do not leave

work.

6. Do not use the machine near flammable, explosive gas, objects!!

7. After machine open, its temperature can reach 400 above, do not touch the °C

preheating plate near the chassis, aluminum mesh.

8. Do not touch the air pressure gun metal parts, heat gun nozzle and jet of hot

air is very hot, don't treat the heat directly spray to the body, is in danger of

burn the body. (853 AA/AAA)

9. Please keep the air pressure gun inlet/outlet flow, there can be no blockages.

(853AA/AAA)

10. Do not touch the iron metal parts, high temperature dangerous! (853AAA)

11. Do not use the soldering iron welding outside of work; Don’t do the soldering

iron percussion work surface to remove fluxes residual, a move that could

seriously damage the iron. (853AAA)

12. When the replacement parts must pull the plug, and cool to room temperature

rear can be carried out.

13. Please put back to handle the heat gun handle frame, machine into sleep

again after power off. (853 AA/AAA)

14. Welding will emit smoke, please get proper ventilation.

15. After use, remember to cooling the fuselage,

WARNING!

1. If the supply cord is damaged, it must be replaced by a special cord or

assemble available from the manufacturer or its service agent.

2. WARNING: This tool must be placed on its stand when not in use.

3. Be careful when using the appliance in places where there are combustible

materials; Do not apply to the same place for a long time.

11

Safety Rules 4. Be aware that heat may be conducted to combustible materials that are out of

sight; Do not leave the appliance unattended when it is switched on.

5. This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge. Unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should

be supervised to ensure that they do not play with the appliance.

I. General Usage

1. Suitable for de-soldering and soldering BGA, SOIC, CHIP, QFP, PLCC packa-

ge SMD IC, particularly suitable for de-soldering BGA module, computer mo-

ther board north and south bridge, all kind of mobile phone motherboard SMT

IC and LED lights.

2. Shrinking, paint drying, adhesive removal, thawing, warming, plastic welding

etc.

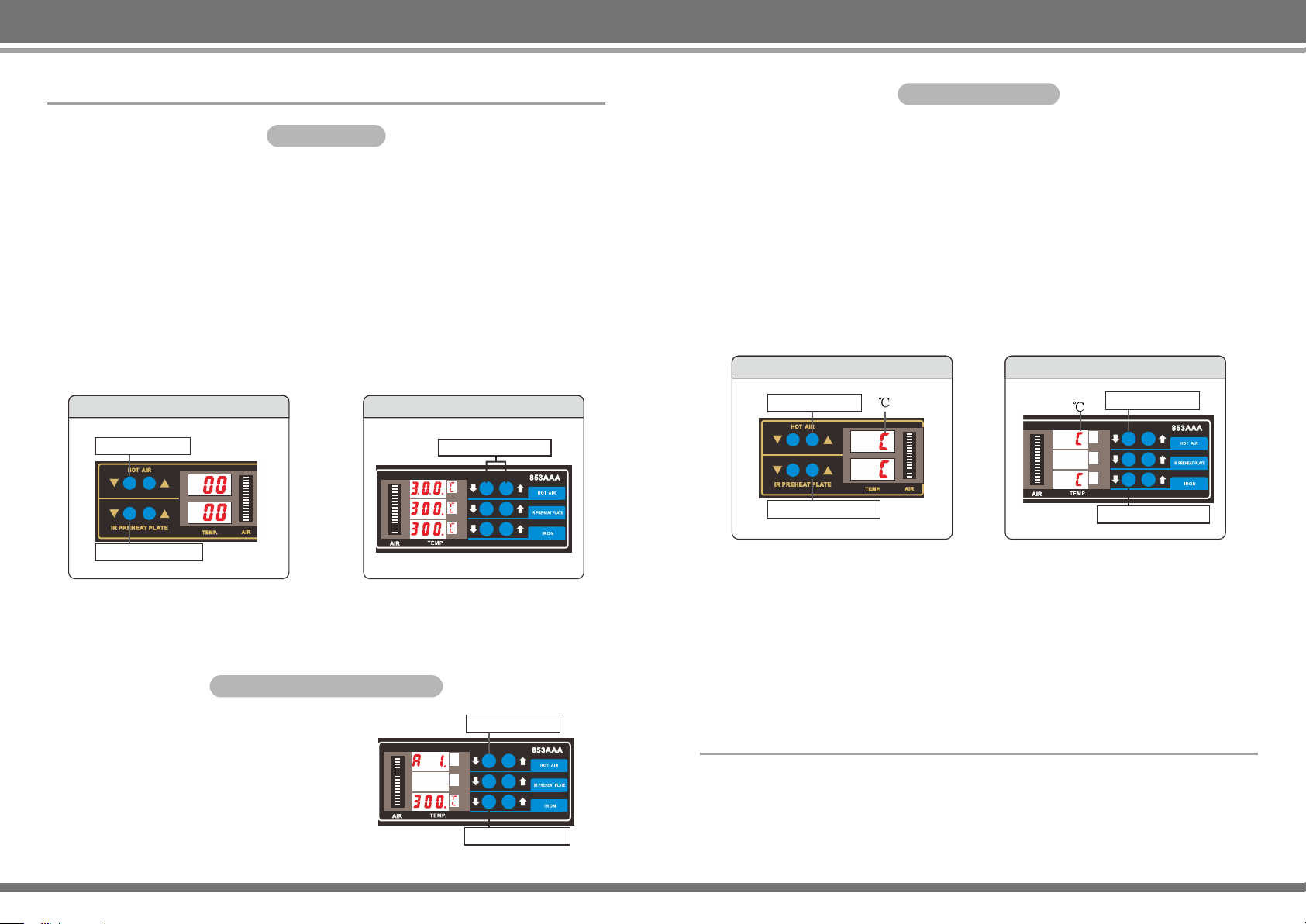

II. Feature

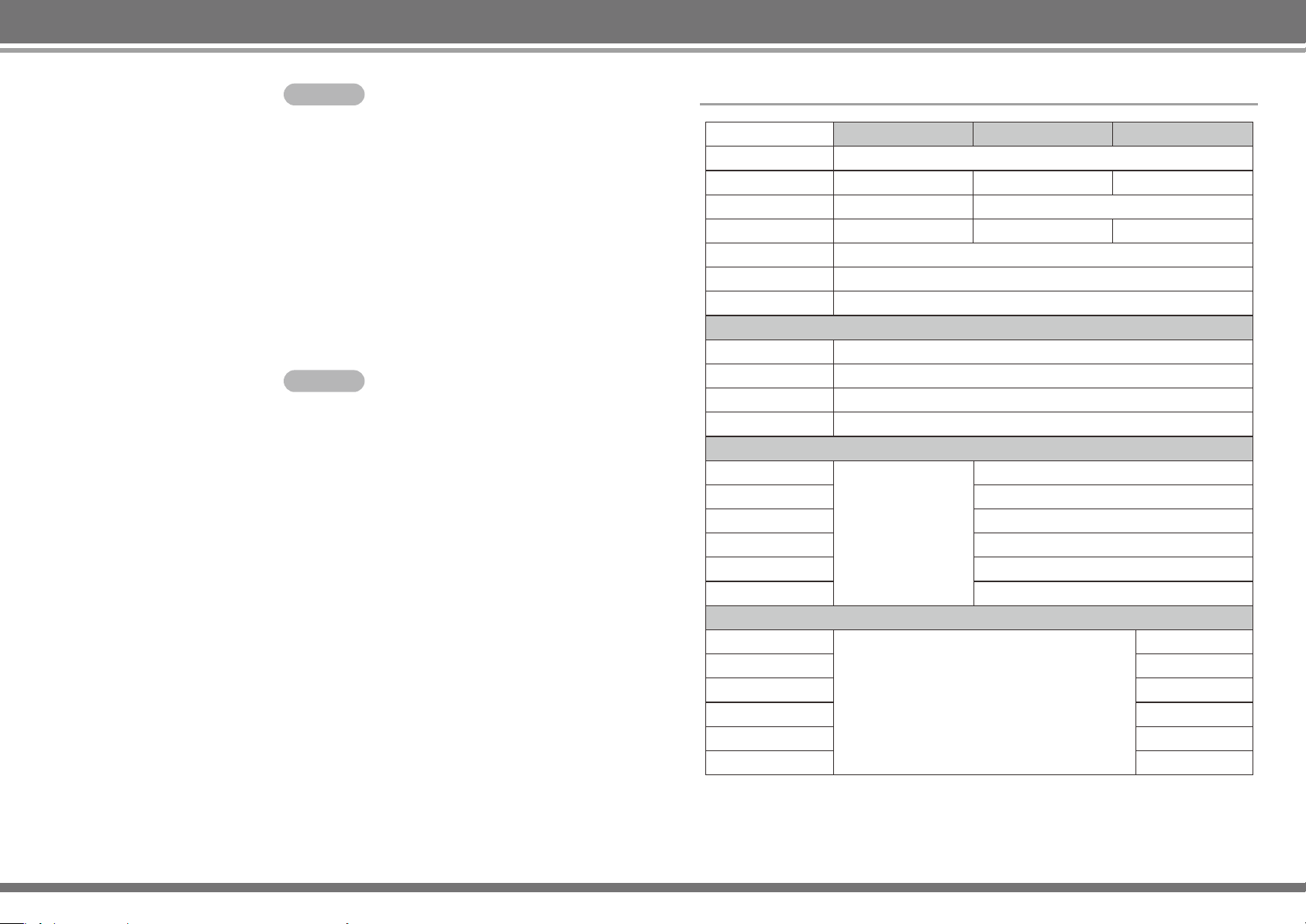

853A

1. Using microcomputer processor PID programmable temperature control techn-

ology, the program cycle every 20 milliseconds to detect the actual temperature

of the heating element and a quick correction, rapid return temperature, tempe-

rature stability LED display, precise preheating station, air gun and soldering

iron temperature.

2. Preheating station is to use a glaze layer having a high thermal effect, good the-

rmal shock resistance of the ceramic as the substrate, high-quality nickel brand-

ed alloy wire once sintering. It has a high thermal effect, overall good, good the-

rmal stability, uniform heating, high dielectric strength, clean, easy to install and

so on features.

3. 853 preheating station practical and easy to operate,the card plate sliding series

bracket bearing technology, to move around durable, convenient card board,

coupled with a fixed sliding bracket screws at the same time, the card board is

solid and reliable.