3

Contents

1 How To Use This Manual .......................................................................................................... 05

2 Unit Designation........................................................................................................................ 06

2.1 Detailed unit designation ...................................................................................................... 06

2.2 Nameplate unit designation.................................................................................................. 07

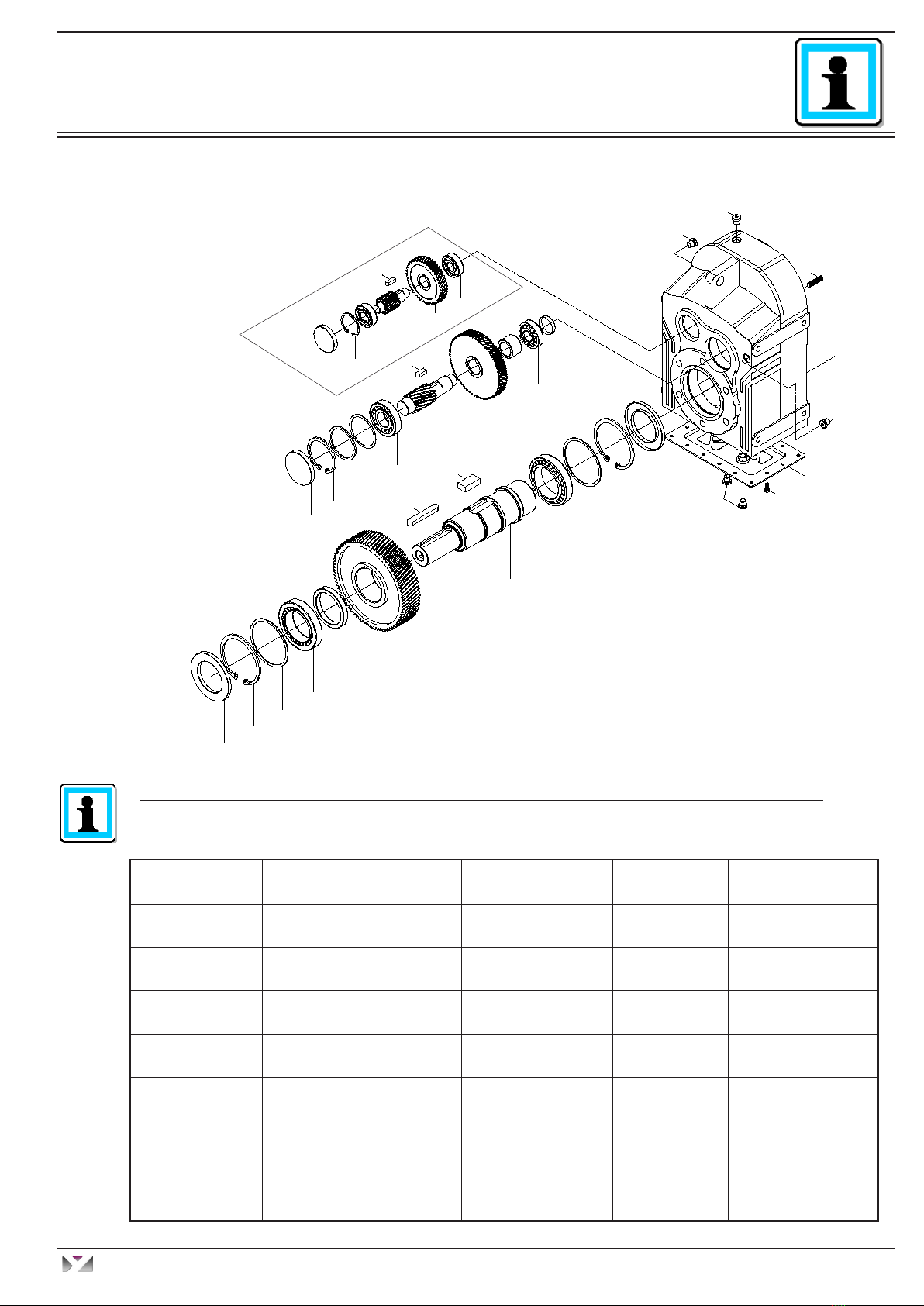

3 Part List of Standard Type Gear Units...................................................................................... 08

3.1 D...00... Type ................................................................................................................... 08

3.2 D...01... Type ................................................................................................................... 09

3.3 D...02... Type. .................................................................................................................. 10

3.4 D...03... Type ................................................................................................................... 11

3.5 D...0S...Type.................................................................................................................... 12

3.6 D...0E... Types................................................................................................................. 13

3.7 D..4 Additional Stage....................................................................................................... 14

3.8 D..5 and D..6 Additional Stages ...................................................................................... 15

3.9 D Series Motor Flange for Direct Coupled Types............................................................ 16

3.10 DN..., DV...Types B5, B14 Motor Flange....................................................................... 16

3.11 DT... Types Input Bearing Housing with Solid Input Shaft ............................................. 17

4- Things to Check Before the Gear Unit or Geared Motor is Installed....................... 18

4.1- Safety notes for use in potentially explosive atmosphere ................................. 18

4.2- Transportation ...................................................................................................19

4.3- Storage..............................................................................................................19

5- Installing the Gear Unit................................................................................................ 20

5.1- Before you start.................................................................................................20

5.2- Check Nameplate of the Gear Unit ................................................................... 20

5.3- Check the Ambient Conditions and Temperature.............................................. 20

5.4- Check Fitting Elements and the Shaft Dimensions to Fit .................................. 20

5.5- Check the Voltage Supply ................................................................................. 22

5.6- Check the Mounting Position ............................................................................ 22

5.7- Usage of Breather Plug..................................................................................... 22

5.8- Check the oil level ............................................................................................. 23

5.9- Check shaft ends and mounting faces .............................................................. 23

5.10- Cover abrasive ambient .................................................................................. 23

5.11- Check accessibility to filling, breather and drain plugs .................................... 23

6- Mechanical Installation................................................................................................ 24

6.1- Installing gear units in category II2G/D-II3G/D.................................................. 24

6.2- Installing Customer Shaft with Shoulder ........................................................... 25

6.3- Disassembling Customer Shaft with Shoulder .................................................. 26

6.4- Fitting Output Shaft Elements ........................................................................... 27

6.5- Correct Position of Output Shaft Elements ....................................................... 27

6.6- Fitting Couplings ............................................................................................... 28

6.7- Shaft Tightening Torques .................................................................................. 29

6.8- Assembling customer shaft with shrink disk..................................................... 30

6.9- Disassembling customer shaft with shrink disk................................................ 32

6.10- Assembling Gear Unit with Torque Arm ......................................................... 33

Operating Instructions

D Series

YILMAZ REDÜKTÖR

Contents