2

Contents............................................................................................................................02

1 - How to Use This Manual.............................................................................................05

2 - Unit Designation..........................................................................................................06

2.1- Detailed Unit Designation.......................................................................................06

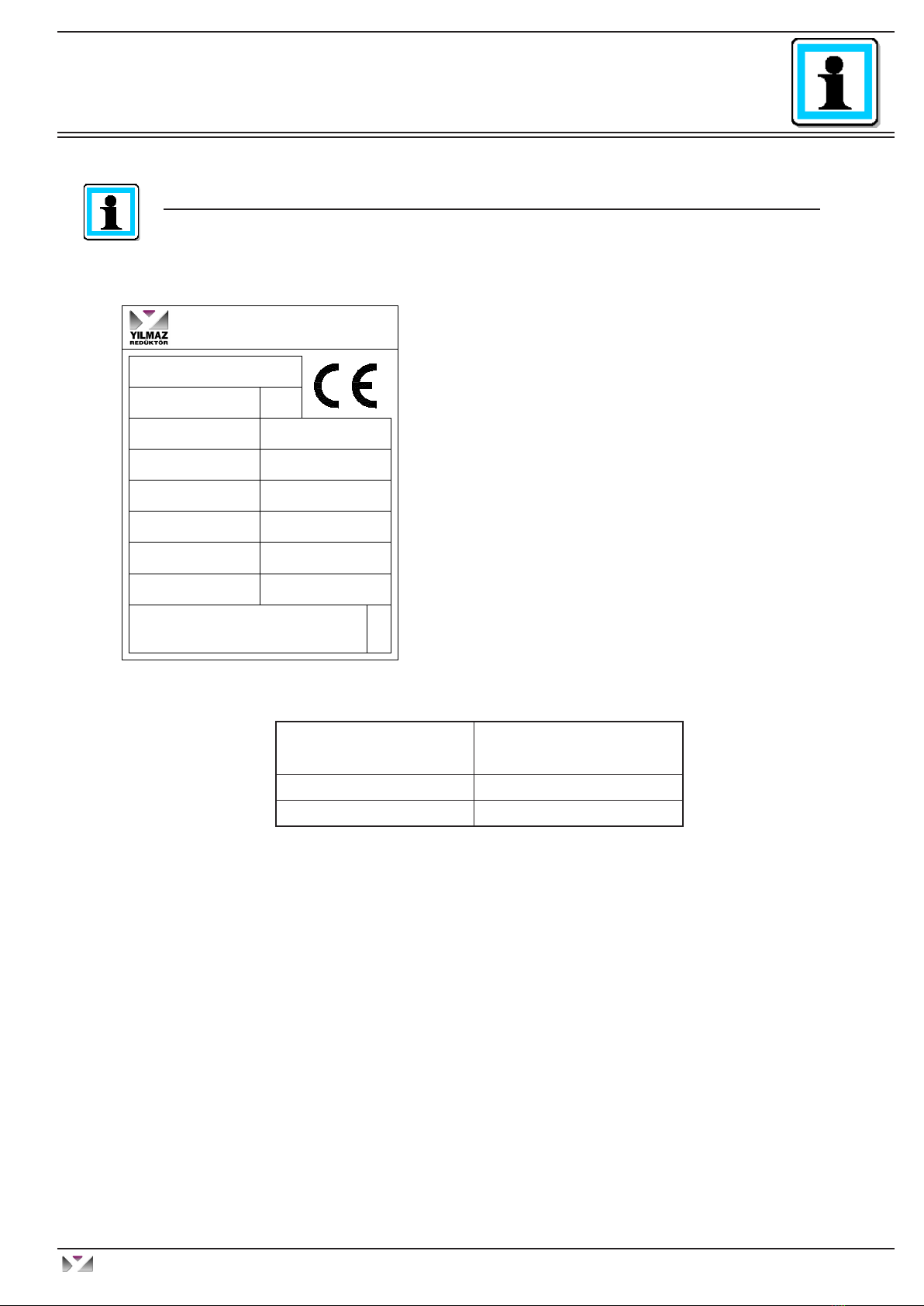

2.2- Nameplate, Unit Designation ....................................................................................07

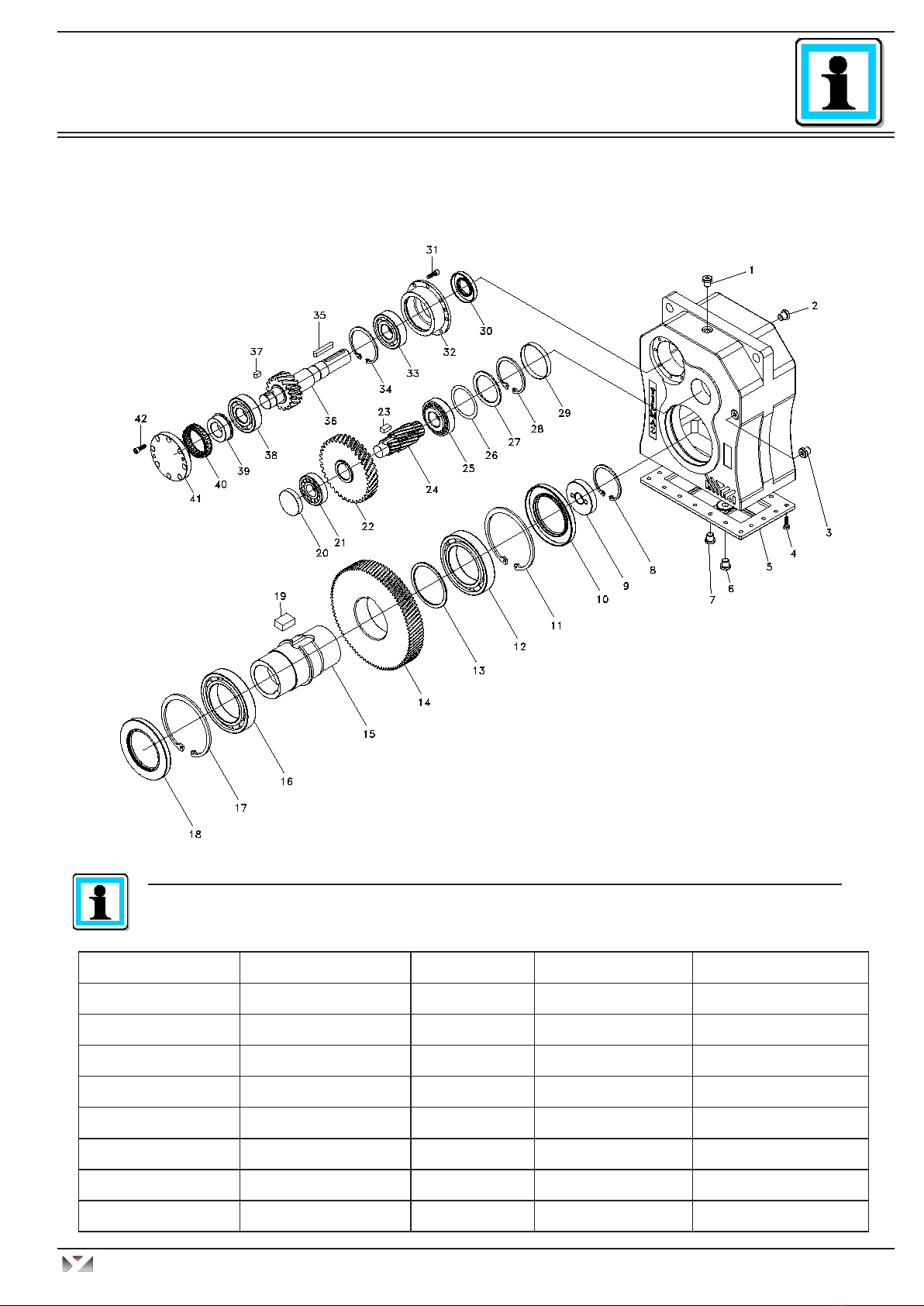

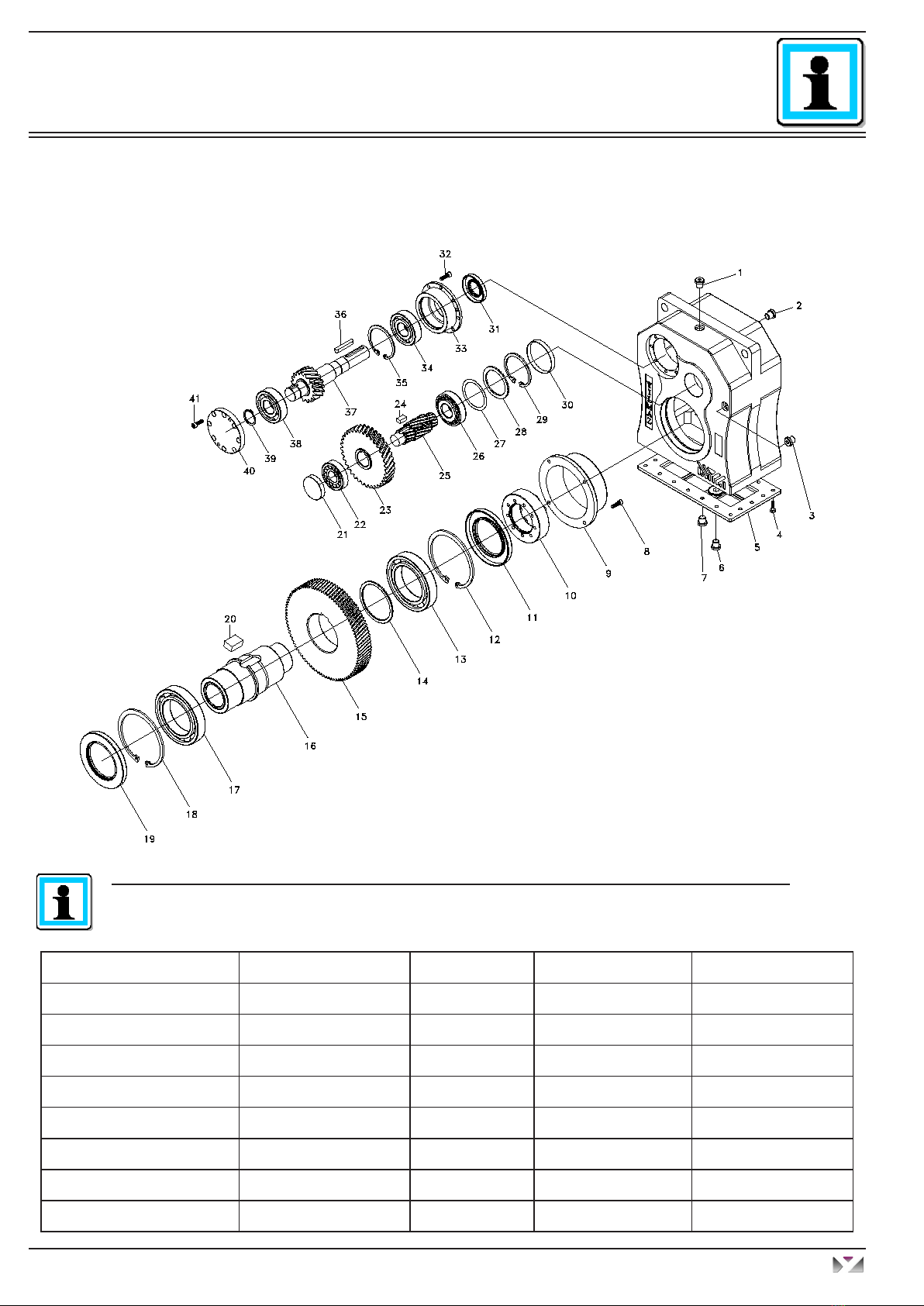

3. Standard Type Gearbox Parts Lists ..............................................................................08

3.1- TT..00 type ...............................................................................................................08

3.2- TT..00.K type ........................................................................................................09

3.3- TT..0S type............................................................................................................10

3.4- TT..0S.K type........................................................................................................ 11

4- Things to Check Before the Gear Unit or Geared Motor is Installed ...................... 12

4.1- Safety notes for use in potentially explosive atmosphere ...................................... 12

Intended use of Gearbox....................................................................................... 12

4.2- Transportation ........................................................................................................13

4.3- Storage...................................................................................................................13

5 - Installing the Gear Unit...............................................................................................14

5.1- Before You Start .....................................................................................................14

5.2- Check Name Plate of the Gear Unit ....................................................................... 14

5.3- Check the Ambient Conditions and Temperature .................................................. 14

5.4- Check Fitting Elements and the Shaft Dimensions to Fit ...................................... 14

5.5- Check the Voltage Supply ...................................................................................... 16

5.6- Check the Mounting Position..................................................................................16

5.7- Usage of Breather Plug.......................................................................................... 16

5.8- Check the oil level ..................................................................................................17

5.9- Check shaft ends and mounting faces ...................................................................17

5.10- Cover abrasive ambients......................................................................................17

5.11- Check accessibility to filling, breather and drain plugs......................................... 17

6- Mechanical Installation................................................................................................18

6.1- Installing gear units in category II2G/D-II3G/D.......................................................18

6.2- Installing Customer Shaft with Shoulder ................................................................ 19

6.3- Installing Customer Shaft without Shoulder ........................................................... 20

6.4- Disassembling Customer Shaft with Shoulder ....................................................... 21

6.5- Disassembling Customer Shaft without Shoulder .................................................. 22

6.6- Shaft Tightening Torques ....................................................................................... 23

6.7- Recommended Shaft Dimensions and Mounting Washer Dimensions.................. 24

6.8- Assembling customer shaft with shrink disk...........................................................25

Operating Instructions

T Series

YILMAZ REDÜKTÖR

Contents