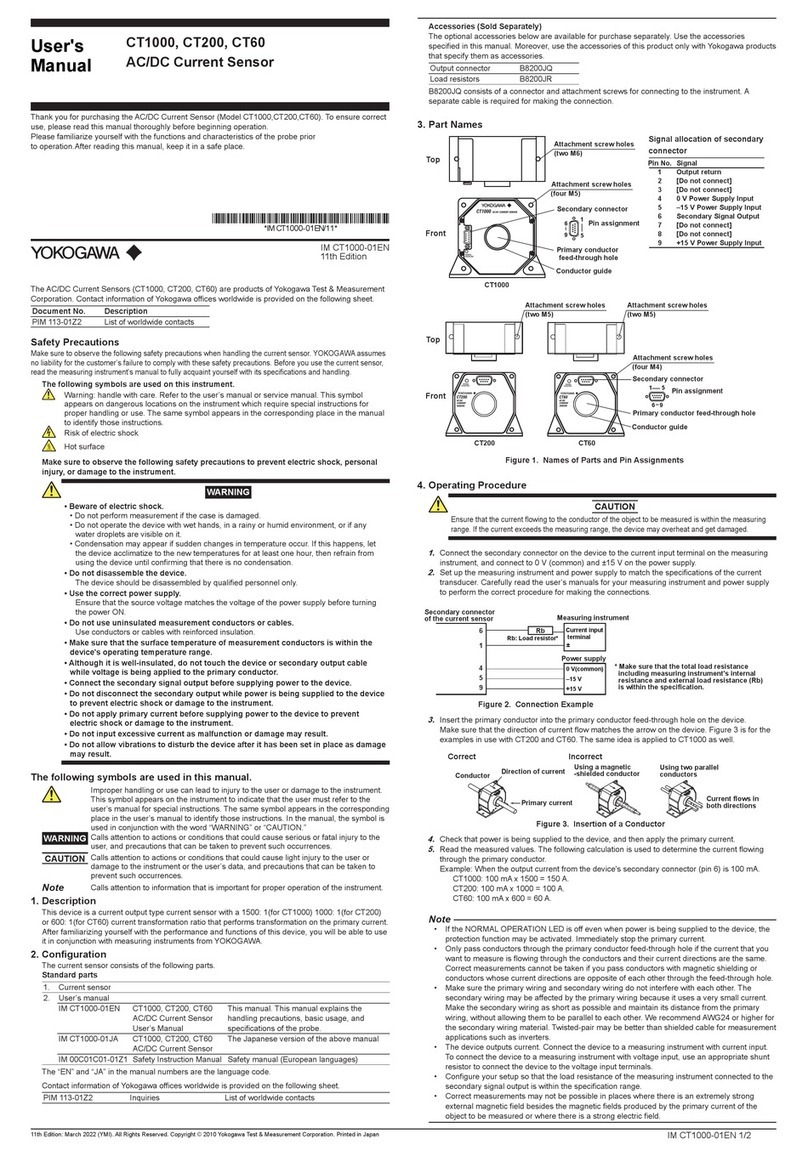

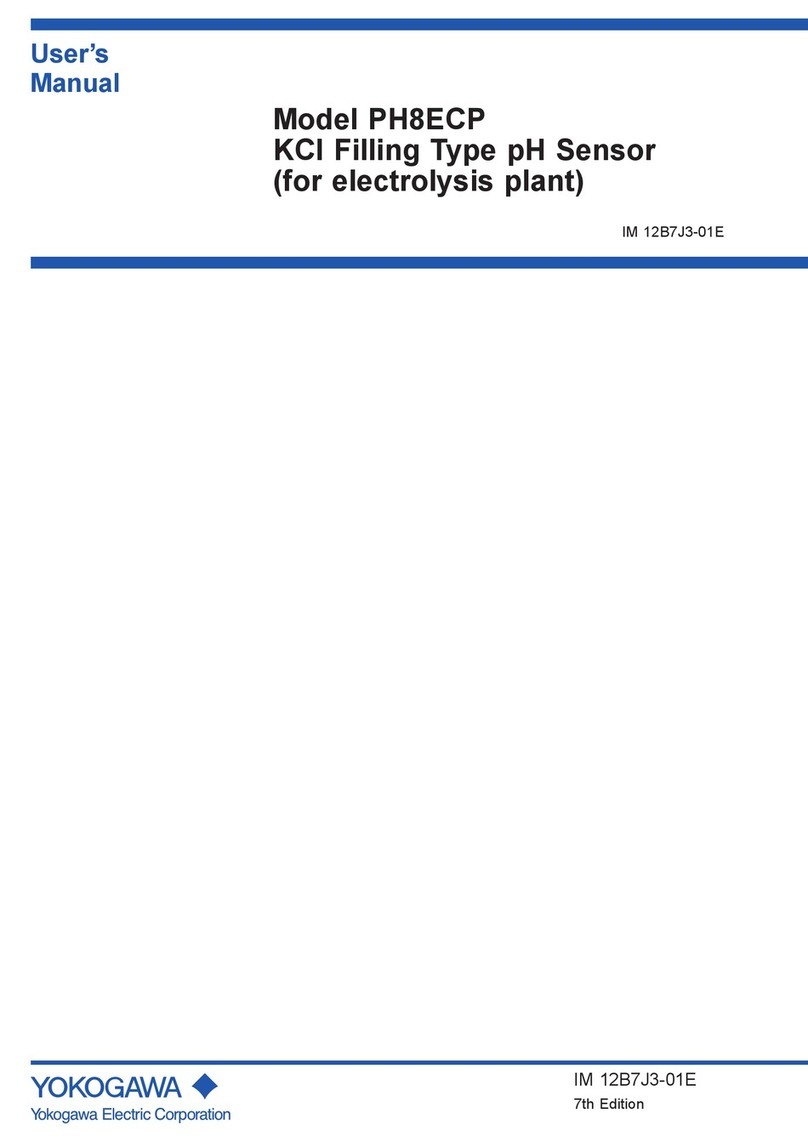

Conductor

Using an magnetic

-shielded conductor

conductors

Current flows in

both directions

Direction of current

Figure 3. Insertion of a Conductor

4.

Check that power is being supplied to the instrument, and then apply the primary current.

5.

Read the measured values. The following calculation is used to determine the current flowing

through the primary conductor.

Example:Whentheoutputcurrentfromtheinstrument'ssecondaryconnector(pin6)is100mA.

CT2000A:100mAx2000=200A

Note

• IftheoperationstatusLEDisoffevenwhenpowerisbeingsuppliedtotheinstrument,the

protection function may be activated. Immediately stop the primary current.

• Onlypassconductorsthroughtheprimaryconductorfeed-throughholeifthecurrentthatyou

want to measure is flowing through the conductors and their current directions are the same.

Correct measurements cannot be taken if you pass conductors with magnetic shielding or

conductorswhosecurrentdirectionsareoppositeofeachotherthroughthefeed-throughhole.

• Makesuretheprimarywiringandsecondarywiringdonotinterferewitheachother.The

secondary wiring may be affected by the primary wiring because it uses a very small current.

Make the secondary wiring as short as possible and maintain its distance from the primary

wiring, without allowing them to be parallel to each other. We recommend AWG24 or higher for

thesecondarywiringmaterial.Twisted-pairmaybebetterthanshieldedcableformeasurement

applications such as inverters.

•The instrument outputs current. Connect the instrument to a measuring instrument with

current input. To connect the instrument to a measuring instrument with voltage input, use an

appropriate shunt resistor to connect the instrument to the voltage input terminals.

•Configure your setup so that the load resistance of the measuring instrument connected to the

secondary signal output is within the specification range.

•Correctmeasurementsmaynotbepossibleinplaceswherethereisanextremelystrong

externalmagneticfieldbesidesthemagneticfieldsproducedbytheprimarycurrentofthe

object to be measured or where there is a strong electric field.

PowerOffIfAbnormalBehaviorOccurs

If you notice smoke or unusual odors coming from the instrument, immediately turn off the

measuring instrument supplying the power. Then, contact your nearest YOKOGAWA dealer.

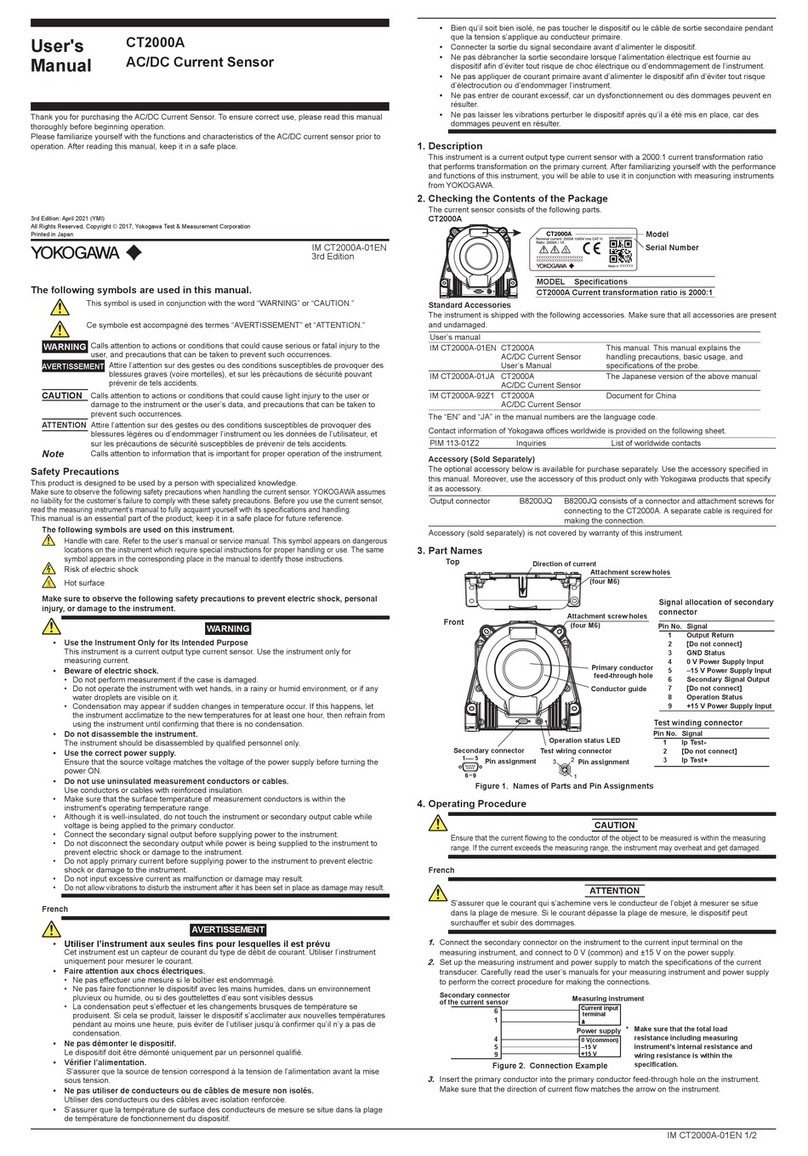

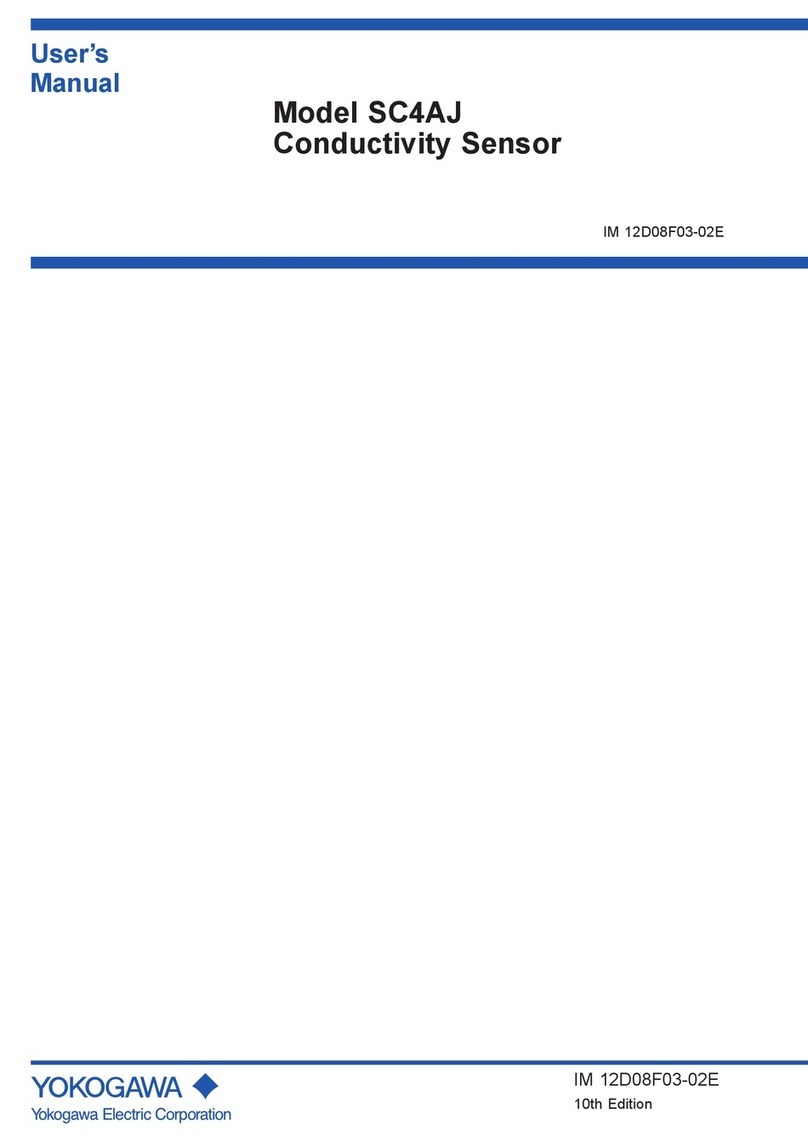

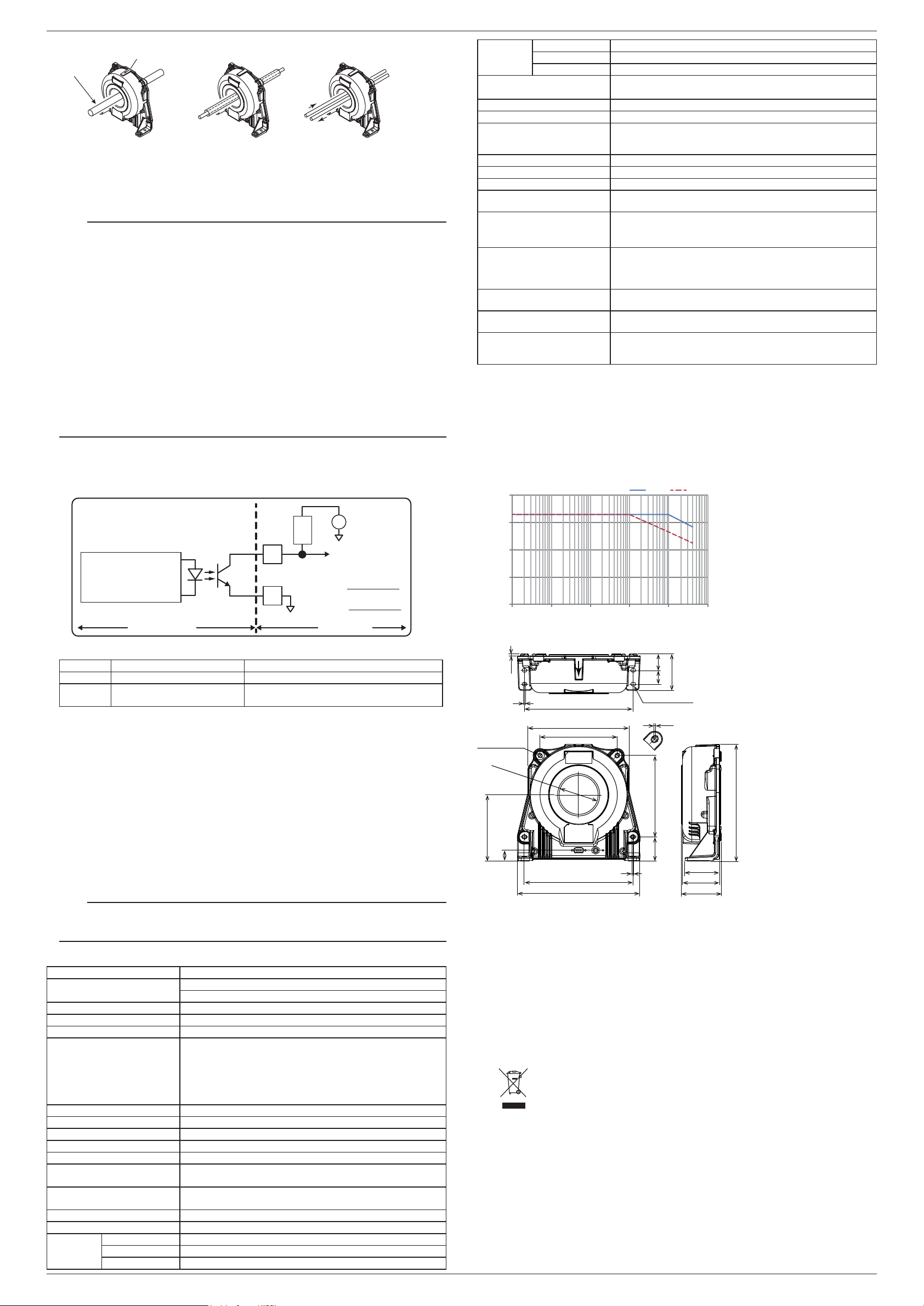

Status circuit diagram

Active Low Output

Operation status

ICEmax : 30 mA

ICEmin : 2 mA

Collector

DC

Power

Supply

R

3

8

+

-

V+ : 4..+24 V

Rmin(kΩ) =

Rmax(kΩ) =

V+(V) - 0.4 V

30 mA

V+(V) - 0.4 V

2 mA

D-Sub

(9 pin)

Emitter

CT2000A USER SIDE

Photocoupler operation:

ON :

CT2000A is OK

(normal mode)

OFF : CT2000A is not OK

Operation status output

Status Operation Status (8-pin) Output Note

Normal Lessthan0.7V TheLEDturnson.

Overloaded V+ TheLEDturnsoff.Alowfrequencysignalisoutput

as a secondary signal output.

Overload Protection

TheoverloadoccurswhentheprimarycurrentIpexceedsatriplevelsuchthatthefluxgatedetector

becomes completely saturated and, consequently, the current sensor will switch from normal

operation to overload mode.

ThistriplevelisguaranteedtobegreaterthanIpm(3000Apeak)anditsactualvaluedependson

operating conditions such as temperatures and measuring resistance.

Duringtheoverloadmode,thecurrentsensorgeneratesandoutputsalowfrequencysignal.

The measuring operation resumes when the primary current returns in the measuring range

between –Ipn and +Ipn (2000Arms).

Test Winding Connector

The test winding connector is used to test the operation of the current sensor.

When a current is applied between the positive and negative Ip test pins, a current that corresponds

tothetestcurrentwindingnumberof200andcurrenttransformationratioof2000:1isoutputfrom

the secondary signal output pin.

Example: When1AisappliedbetweenthepositiveandnegativeIppins,100mAisoutputfromthe

secondary signal output pin.

Note

To measure the current of the primary conductor that has been passed through the through hole,

donotconnectanythingtothetestwindingIp+orIp-pin.Ifconnected,errorsmaybeinducedin

the sensor output.

5. Specifications

Item Specification

Current Rating DC:0to2000A

AC:3000Apeak

Output Current Primaryratedcurrentat2000Ais1A.

Current Transformation Ratio 2000:1

DirectionofCurrent Per the arrow printed on the main unit.

Accuracy DC:±(0.05%ofreading+30μA)

50/60Hz:±(0.05%ofreading+30μA)sinewave

Standard Conditions

Voltage to earth: 0V

Conductor position: center

Conductor:φ25mm;length,300mmormore;straight

Accuracy warranty period 12months

Effect of Position of Conductor Add±(0.01%ofreading)

MeasurementBand(-3dB) DCto40kHz

Temperature Coefficient Inthe-40to18°C,28to85°Cranges:0.01%/°C

Max.AllowableContinuousInput 3000Apeak

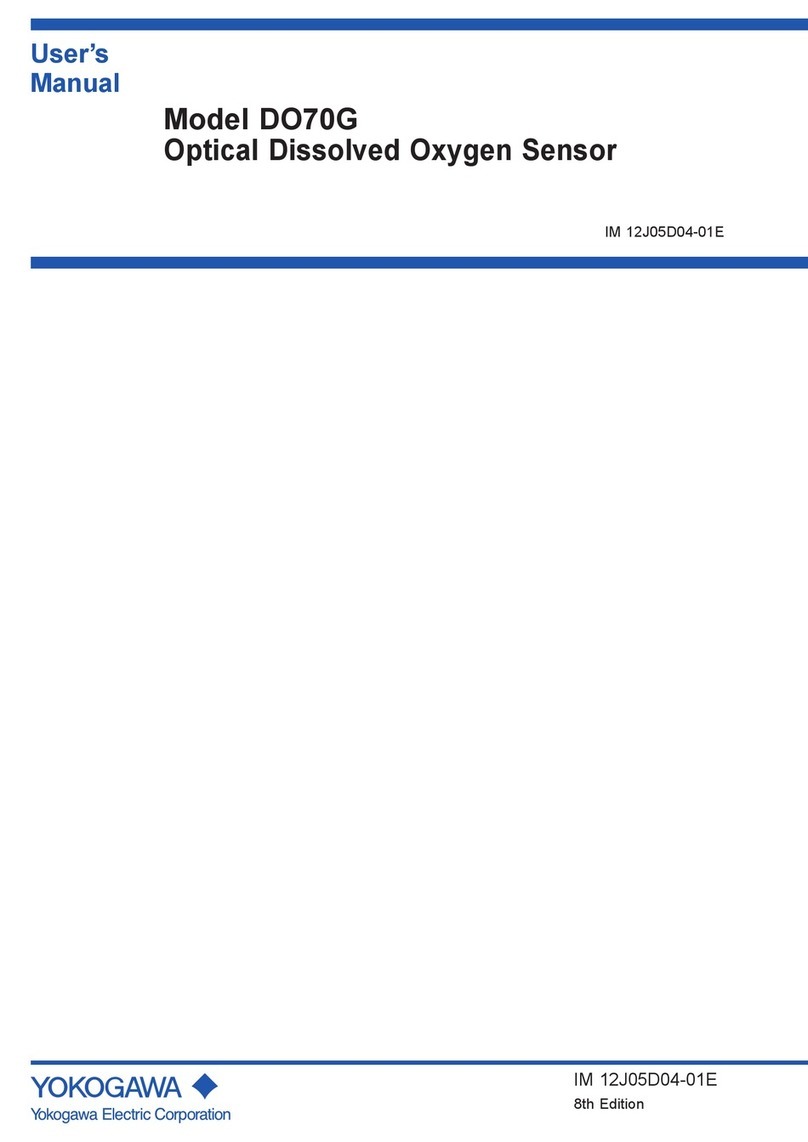

DeratingofMax.AllowableInput Forthemaximumallowablecontinuouscurrentwithrespectto

frequency, see figure 4.

InstantaneousMax.AllowableInput

(0.1sec.orless,referencevalue)

10000Apeak

MaximumRatedVoltage 1000Vrms,CATIII

LoadResistance 0to1Ω(powersupplyvoltage:±14.25V,25°C)

Operating

environment

Temperature -40to85°C

Humidity 20to80%RH(nocondensation)

Altitude 2000 m or less

IMCT2000A-01EN2/2

Storage

environment

Temperature -40to85°C

Humidity 20to80%RH(Nocondensation)

Altitude 2000 m or less

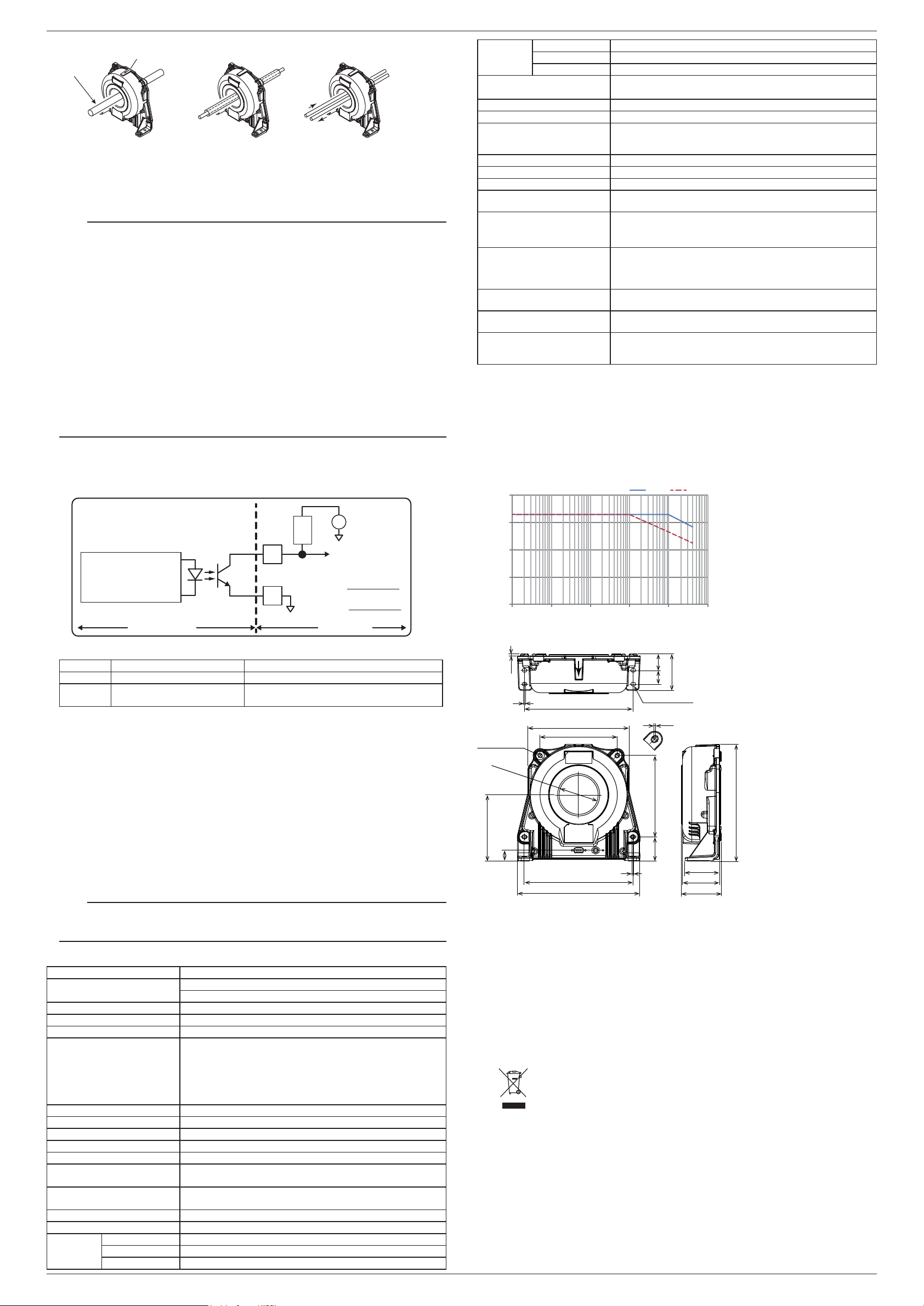

ExternalDimensions Approx.230.5(W)x219.5(H)x75.5(D)mm

(excludingtheconnector,conductorguide,andprotrusions)

DiameterofPrimaryCurrentHole φ70mm

Secondary Connector D-Sub9pin

Test Wiring Connector M8circular3pin

Testcurrent:1Amax.

Number of test windings: 200

Weight Approx.4.2kg.

Power Supply Voltage ±(15V±5%)

MaximumRatedPowerConsumption

Approx.35VA

Current Consumption (at Power

Supply Voltage)

Approx.(225mA+outputcurrent)

Recommended fastening torque

•Flatmounting M6×4steelscrews5.5Nm

M6×4steelscrews5.5Nm

•Straightmounting

Safety standard1Compliant standards

EN61010-11000Vrms

Measurement Category: CAT III2

Pollution degree 23

Emissions Compliant standards

EN61326-1ClassB,EN55011ClassB,Group1

Immunity Compliant standards

EN61326-1Table2(forindustriallocations)

Environmental standard Compliant standards

EN50581Monitoringandcontrolinstrumentsincludingindustrial

monitoring and control instruments.

1 AppliestoproductswithCEmarks.Forinformationonotherproducts,contactyournearestYOKOGAWAdealer.

2 ThisinstrumentismeasurementcategoryIIIproduct.DonotuseitforMeasurementCategoriesIV.

Measurement category O applies to measurement of other circuits that are not directly connected to a main power

supply.

MeasurementcategoryIIappliestoelectricalequipmentthatispoweredthroughafixedinstallation,suchasa

wall outlet wired to a distribution board, and to measurement performed on such wiring.

Measurement category III applies to measurement of facility circuits, such as distribution boards and circuit

breakers.

Measurement category IV applies to measurement of power source circuits, such as entrance cables to buildings

and cable systems, for lowvoltage installations.

3 PollutionDegreeappliestothedegreeofadhesionofasolid,liquid,orgaswhichdeteriorateswithstandvoltageor

surfaceresistivity.Pollutiondegree2appliestonormalindooratmospheres(withonlynon-conductivepollution).

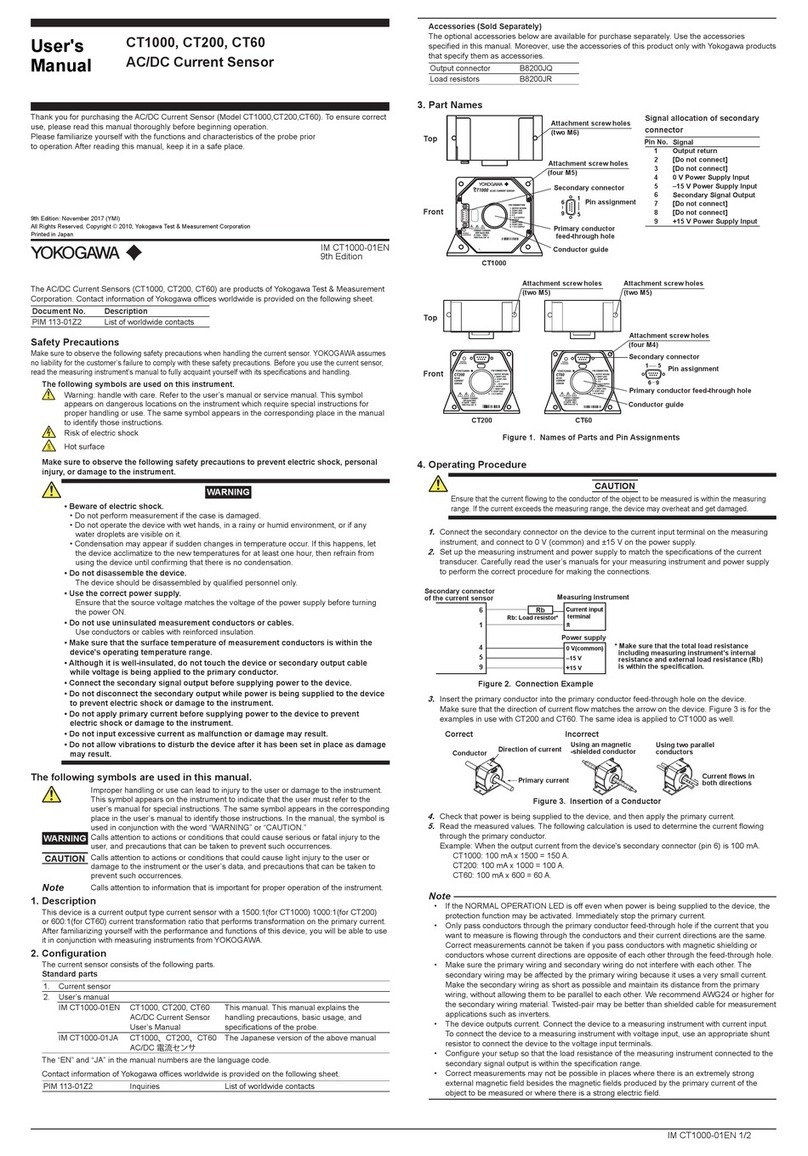

Figure 4. Derating of Primary Current by Frequency

Frequency [Hz]

Maximum Allowable Input Current [Arms]

1

10

100

1000

10000

1 10 100 1000 10000 100000

190.5

145

45.3 153

204

230.5

65

69.5

75.5

219.5

Φ70+1

0

hole

20

1.4

(2)

31

26

68.5

204 4-Φ7x9 hole

(2)

3.5

Figure 5. External Dimensions

Unless otherwise specified, tolerances are ±3% (however, tolerances are ±

0.3 mm when below 10 mm).

Unit: mm

6. Servicing

If you encounter any problems during use, or if the instrument does not appear to be operating

normally, contact your nearest YOKOGAWA dealer.

7. Warranty

Ifyouexperienceabreakdownintheinstrumentduetofaultymanufacturingoraccidentsduring

shipping, contact your nearest YOKOGAWA dealer.

8. Appendix

WasteElectricalandElectronicEquipment(WEEE),Directive

(This directive is valid only in the EU.)

ThisproductcomplieswiththeWEEEDirectivemarkingrequirement.Thismarking

indicates that you must not discard this electrical/electronic product in domestic

household waste.

Product Category

With reference to the equipment types in the WEEE directive, this product is classified

as a “Monitoring and Control instruments” product.

When disposing products in the EU, contact your local Yokogawa Europe B. V. office.

Donotdisposeindomestichouseholdwaste.

Authorized Representative in the EEA

YokogawaEuropeB.V.isAuthorizedRepresentativeofYokogawaTest&MeasurementCorporation

in the EEA for this Product. To contact Yokogawa Europe B. V., see the separate list of worldwide

contacts,PIM113-01Z2.

DisposingoftheInstrument

When disposing of the instrument, follow the laws and ordinances of your country or region.