22250 Hydrostatic Level Sensor

Refer to your local Georg Fischer Sales office for the most

current warranty statement.

All warranty and non-warranty repairs being returned must

include a fully completed Service Form and goods must be

returned to your local GF Sales office or distributor.

Product returned without a Service Form may not be

warranty replaced or repaired.

Signet products with limited shelf-life (e.g. pH, ORP, chlorine

electrodes, calibration solutions; e.g. pH buffers, turbidity

standards or other solutions) are warranted out of box but not

warranted against any damage, due to process or application

failures (e.g. high temperature,

chemical poisoning, dry-out) or

mishandling (e.g. broken glass,

damaged membrane, freezing

and/or extreme temperatures).

Thank you for purchasing the Signet line of Georg Fischer

measurement products.

If you would like to register your product(s), you can now

register online in one of the following ways:

• Visit our website www.gfsignet.com.

Under Service and Support click on

Product Registration Form

• If this is a pdf manual (digital copy), click here

Warranty Information

Product Registration

Safety Information

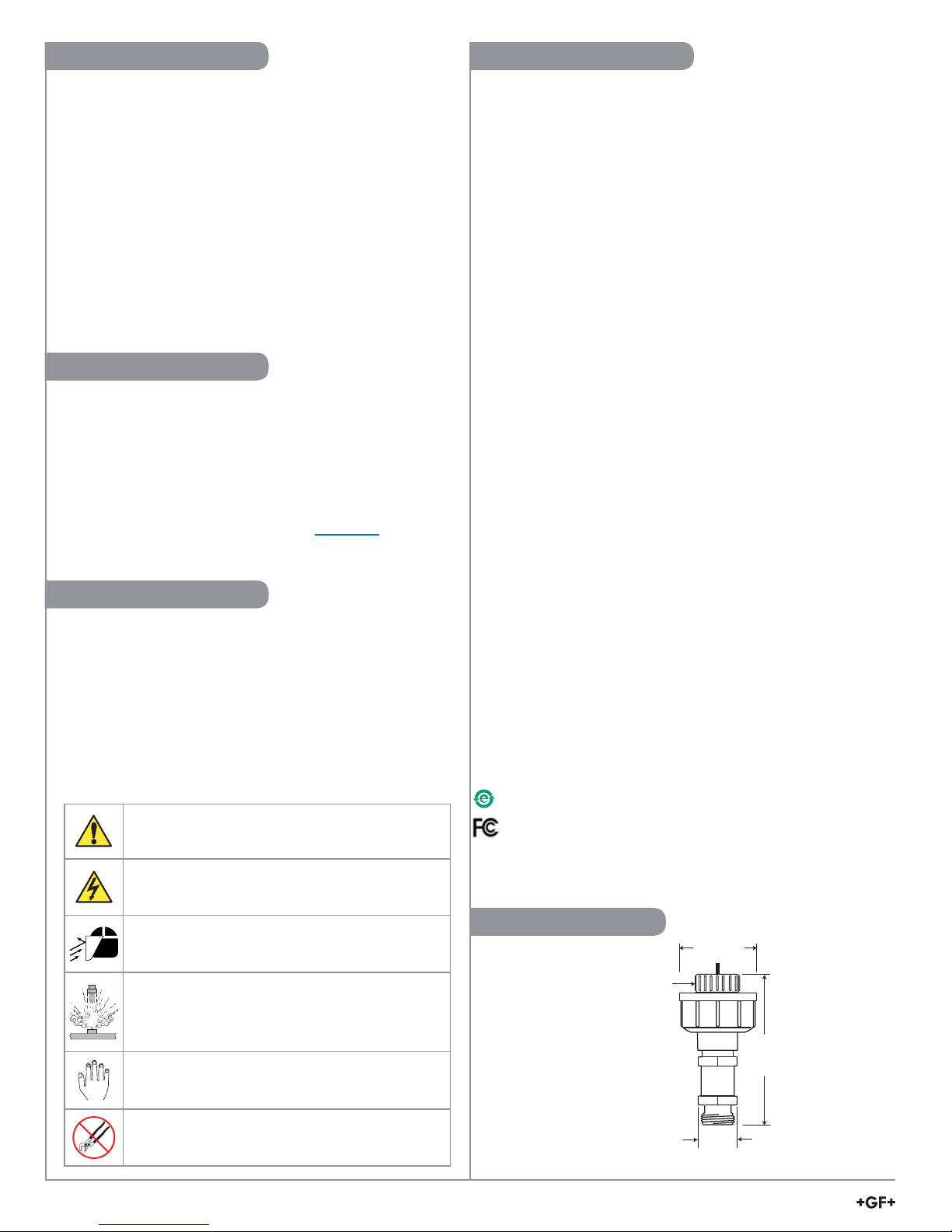

Dimensions

1. Prior to installation or removal:

• Depressurize and vent system

• Drain below sensor level

2. Confirm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure

specifications.

4. Wear safety goggles or faceshield during installation/

service.

5. Do not alter product construction.

6. Dispose of properly; DO NOT INCINERATE!

½ in. (ANSI) or

25 mm (ISO)

Solvent Socket,

PVC-U

34 mm

(1.32 in)

115 mm

(4.55 in)

53 mm

(2.09 in)

General

Compatibility .............................. Signet 8900 Multi-Parameter Controller

Signet 9900 Transmitter

Signet 9950 Dual Channel Transmitter

Wetted Material

Sensor housing ......................... PVDF

Union nut/bushing ..................... PVC-U

Diaphragm................................. Ceramic

Diaphragm seal.........................FKM (optional EPDM)

Cable type .................................22 AWG, 3 conductor+capillary tube

Cable length ..............................10 m (32.8 ft) supplied

max. extension 120 m (400 ft)

Operating Temperature............. 15 °C to 85 °C (5 °F to 185 °F)

Storage Temperature................-20 °C to 100 °C (-4 °F to 212 °F)

Operating Pressure:.................. -XU: 0 to 0.7 bar (0 to 10 psig)

-XL: 0 to 3.4 bar (0 to 50 psig)

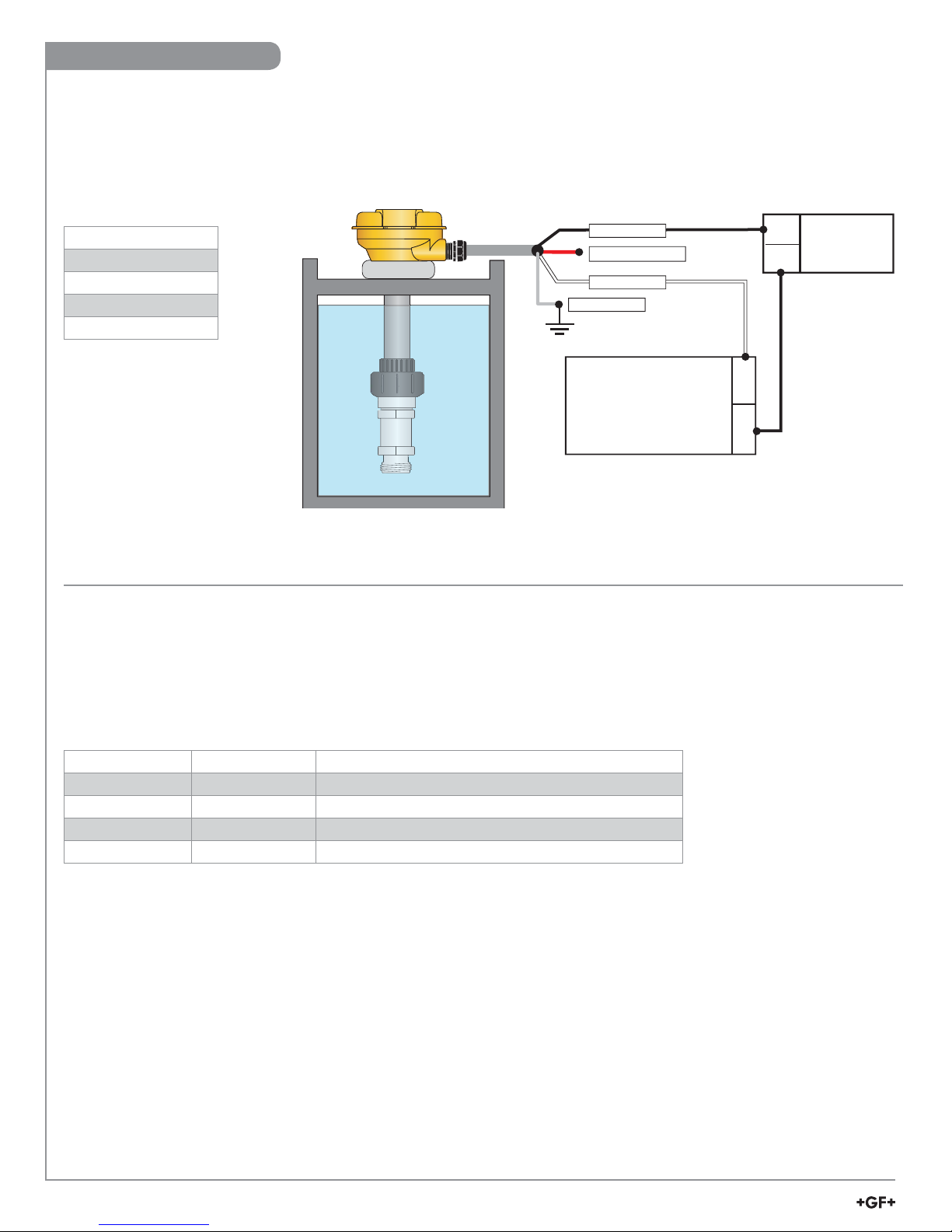

Electrical

Digital (S3L) Output

Format .......................................Serial ASCII, TTL level 9600 bps.

Accuracy.................................... ±1% of full scale (±0.001 psi)

Power.........................................5 VDC nominal, 1.5 mA max. current

(5 VDC min, 6.5 VDC max)

Reverse polarity and short circuit protected

4 to 20 mA Output

Factory span

-XU.............................................0 to 0.7 bar (0 to 10 psig) =

0 m to 7 m (0 ft to 23 ft) of water

-XL.............................................. 0 to 3.4 bar (0 to 50 psig) =

0 m to 34 m (0 ft to 115.5 ft) of water

Accuracy.................................... ± 32 μA

Resolution.................................. < 5 μA

Response Time .........................< 100 ms

Loop Power Required...............12 to 24 VDC nominal, 22.1 mA max

(10.8 VDC min. to 26.4 VDC max.)

Max. Loop Impedance.............. 100 Ω@ 12 V

325 Ω@ 18 V

600 Ω@ 24 V

Standards and Approvals

CE

RoHS Compliant

Manufactured under ISO 9001 for Quality, ISO 14001 for

Environmental Management and OHSAS 18001 for Occupational

Health and Safety.

China RoHS (Go to www.gfsignet.com for details)

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and,

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Specifications

Caution / Warning / Danger

Indicates a potential hazard. Failure to follow all warnings

may lead to equipment damage, injury, or death

Electrostatic Discharge (ESD) / Electrocution Danger

Alerts user to risk of potential damage to product by ESD,

and/or risk of potential of injury or death via electrocution.

Personal Protective Equipment (PPE)

Always utilize the most appropriate PPE during

installation and service of Signet products.

Pressurized System Warning

Sensor may be under pressure, take caution to vent

system prior to installation or removal. Failure to do so

may result in equipment damage and/or serious injury.

Hand Tighten Only

Overtightening may permanently damage product threads

and lead to failure of the retaining nut.

Do Not Use Tools

Use of tool(s) may damage product beyond repair and

potentially void product warranty.