YOKOGAWA SA11 User manual

IM 12A06S01-00EN-P

3rd edition

Instruction

Manual

Model SA11

Smart Adapter

IM 12A06S01-00EN-P

2

Introduction

Thank you for purchasing the SA11 Smart Adapter. Please read the following respective

documents before installing and using the SA11. The SA11 Smart Adapter only works with

Yokogawa sensors equipped with an ID-chip. If sensors without ID-chip are connected, all

calculated output data of the SA11 will be disabled.

When the FLXA402 or UM33A-S00 is used as HOST of the SA11 slave device, please refer

to the User’s Manual IM 12A01F01-02 or IM 05P09D21-01EN too.

For the general specifications of the SA11 please refer to the GS 12A06S01-00EN-(P).

The related documents are as follows.

General Specifications

Contents Document number Note

SA11 Smart Adapter GS 12A06S01-00EN-(P) Available for

FLXA402 4-wire Analyzer GS 12A01F01-01EN download

UM33A-S00 Digital Indicator GS 05P03D21-01EN

BA11 Active Junction Box GS 12B06W03-01E-E

Fieldmate GS 01R01A01-01E

IB100 GS 12B06J09-01E-E

WU10/WE10 VP- and Ext. cable GS 12B06W02-02E-E

WU11 Interconnection cable GS 12B06W02-03E-E

User’s Manual

Contents Document number Note

SA11 Smart Adapter

Start-up Manual IM 12A06S01-01Z1-(P) Attached to the product

SA11 Smart Adapter

User’s Manual (English version) IM 12A06S01-00EN-(P) Available for download

SA11 Smart Adapter

User’s Manual (Japanese version) IM 12A06S01-00JA-(P) Available for download

FLXA402 4-wire Analyzer

Start-up Manual IM 12A01F01-01EN Attached to the product

FLXA402 4-wire Analyzer

User’s Manual IM 12A01F01-02EN Available for download

UM33A-S00 Digital Indicator IM 05P09D21-11EN Attached to the product

BA11 Active Junction Box IM 12B06W03-01E-E Attached to the product

WU11 Interconnection cable IM 12B06W02-03E-E Attached to the product

WU10/WE10 VP- and Ext. cable IM 12B06W02-02E-E Attached to the product

Note: The “E” or “EN” in the document number is the language code for English version,

the “JA” indicates the Japanese version and the “Z” indicates it is a multi-language

document.

Downloads can be done from: https://www.yokogawa.

com/solutions/products-platforms/process-analyzers/liquid-

analyzers/#Downloads

You can use the QR-code for quick-access.

IM 12A06S01-00EN-P

3

Notes on Handling User’s Manuals

• Please hand over the user’s manuals to your end users so that they can keep the user’s

manuals on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to

any purpose but rather to describe the functional details of the product.

• No part of the user’s manuals may be transferred or reproduced without prior written

consent from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product

at any time, without notice or obligation.

• If you have any questions, or you find mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

Drawing Conventions

Some drawings may be partially emphasized, simplified, or omitted, for the convenience of

description. Some screen images depicted in the user’s manual may have different display

positions or character types (e.g., the upper / lower case). Also note that some of the

images contained in this user’s manual are display examples.

Composition of this User’s Manual

Contents pH/ORP Specific Conductivity

Introduction and general description Section 1

Wiring and installation Section 2

Operation Section 3 Section 6

Commissioning Section 4 Section 7

Calibration Section 5 Section 8

Maintenance Section 9

Troubleshooting Section 10

Appendices Section 11

IM 12A06S01-00EN-P

4

Safety Precautions

Safety, Protection, and Modification of the Product

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this user’s manual. We

assume no liability for safety if users fail to observe these instructions when operating the

product.

• If this instrument is used in a manner not specified in this user’s manual, the protection

provided by this instrument may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepares it separately.

• Be sure to use the spare parts approved by Yokogawa Process Analyzers (simply referred

to as YOKOGAWA) when replacing parts or consumables.

• Modification of the product is strictly prohibited.

• The following safety symbols are used on the product as well as in this manual.

WARNING

This symbol indicates that an operator must follow the instructions laid out in this manual

to avoid the risks, for the human body, of injury, electric shock, or fatalities. The manual

describes what special care the operator must take to avoid such risks.

CAUTION

This symbol indicates that the operator must refer to the instructions in this manual

to prevent the instrument (hardware) or software from being damaged, or a system

failure from occurring.

CAUTION

This symbol gives information essential for understanding the operations and functions.

NOTE

This symbol indicates information that complements the present topic.

This symbol indicates Protective Ground Terminal.

This symbol indicates Function Ground Terminal. Do not use this terminal as the protective

ground terminal.

IM 12A06S01-00EN-P

5

Warning and Disclaimer

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor

responsibility to any person or entity with respect to any direct or indirect loss or damage

arising from using the product or any defect of the product that YOKOGAWA cannot predict

in advance.

SA11

• The SA11 should only be used with equipment that meets the relevant IEC, American,

Canadian, and Japanese standards. Yokogawa accepts no responsibility for the misuse of

this unit.

• The Instrument is packed carefully with shock absorbing materials, nevertheless, the

instrument may be damaged or broken if subjected to strong shock, such as if the

instrument is dropped. Handle with care.

CAUTION

Electrostatic discharge

The SA11 contains devices that can be damaged by electrostatic discharge.

When servicing this equipment, please observe proper procedures to prevent such damage.

CAUTION

Do not use an abrasive or organic solvent in cleaning the instrument.

CAUTION

This device is an EN61326-1 Class A product, and it is designed for use in the industrial

environment. The device however can be used in a laboratory environment too.

CAUTION

Be careful to touch the concentrated sulfuric acid.

IM 12A06S01-00EN-P

6

Product Disposal

The instrument should be disposed of in accordance with local and national legislation/

regulations.

Warranty and service

Yokogawa products and parts are guaranteed free from defects in workmanship and

material under normal use and service for a period of (typically) 12 months from the date of

shipment from the manufacturer.

Individual sales organizations can deviate from the typical warranty period, and the

conditions of sale relating to the original purchase order should be consulted. Damage

caused by wear and tear, inadequate maintenance, corrosion, or by the effects of chemical

processes are excluded from this warranty coverage.

In the event of warranty claim, the defective goods should be sent (freight paid) to the

service department of the relevant sales organization for replacement (at Yokogawa

discretion).

The following information must be included in the letter accompanying the returned goods:

• Part number, model code and serial number

• Original purchase order and date

• Length of time in service and a description of the process

• Description of the fault, and the circumstances of failure

• Process/environmental conditions that may be related to the failure of the device.

• A statement whether warranty or non-warranty service is requested

• Complete shipping and billing instructions for return of material, plus the name and phone

number of a contact person who can be reached for further information.

Returned goods that have been in contact with process fluids must be decontaminated /

disinfected before shipment. Goods should carry a certificate to this effect, for the health

and safety of our employees.

Material safety data sheets should also be included for all components of the processes to

which the equipment has been exposed.

Copyright and Trademark Notices

The online manual is protected by the PDF security from modification, however, it can be

output via a printer. Printing out the online manual is only allowed for using the product.

When using the printed information of the online manual, check if the version is the most

recent one by referring to the version attached to the product.

No part of the online manual may be transferred, sold, distributed (including delivery via a

commercial PC network or the like), or registered or recorded on video tapes.

FLEXA, FLXA, SENCOM and FieldMate are trademarks or registered trademarks of

Yokogawa Electric Corporation.

Adobe, Acrobat and Acrobat Reader are either registered trademarks or trademarks of

Adobe Systems Incorporated in the United States and/or other countries.

All other company and product names mentioned in this user’s manual are trademarks or

registered trademarks of their respective companies.

We do not use TM or ® mark to indicate those trademarks or registered trademarks in this

user’s manual.

IM 12A06S01-00EN-P

7

SA11 fonts

(c) Copyright 2000-2001 /efont/ The Electronic Font Open Laboratory. All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are

permitted provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of

conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of

conditions and the following disclaimer in the documentation and/or other materials

provided with the distribution.

3. Neither the name of the team nor the names of its contributors may be used to endorse

or promote products derived from this font without specific prior written permission.

THIS FONT IS PROVIDED BY THE TEAM AND CONTRIBUTORS “AS IS” AND ANY

EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE TEAM OR CONTRIBUTORS

BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR

CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF

SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN

CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE)

ARISING IN ANY WAY OUT OF THE USE OF THIS FONT, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

CE marking products

Authorized Representative in EEA

The Authorized Representative for this product in EEA is Yokogawa Europe B.V.,

Euroweg 2, 3825 HD Amersfoort, The Netherlands.

Identification Tag

This manual and the identification tag attached on a packing box are essential parts of the

product. Keep them together in a safe place for future reference.

Users

This product is designed to be used by a person with specialized knowledge.

IM 12A06S01-00EN-P

8

Contents

Introduction 2

General Specifications 2

User’s Manual 2

Safety Precautions 4

Warning and Disclaimer 5

Product Disposal 6

Warranty and service 6

Copyright and Trademark Notices 6

CE marking products 7

1 INTRODUCTION AND GENERAL DESCRIPTION 11

1.1. Instrument check 11

1.2. Checking the accessories 12

1.3. Regulatory Compliance 12

1.4. Model & Suffix Codes 13

1.5. Spare part list 13

2 WIRING AND INSTALLATION 14

2.1 Installation site 14

2.2 Connecting to the sensor 14

2.2.1 Direct mounting 14

2.2.2 Cable mounting 15

2.3 Wiring to the HOST system 15

2.3.1 Wired connection 15

2.3.2 Connection in daisy chain concept 15

2.3.3 Wireless connection 16

2.3.4 Grounding 16

2.4 Operation 17

3 OPERATION OF pH/ORP 17

3.1 SA11 quick setup 17

3.2 Measurement setup 17

3.2.1 Parameter setting 17

3.2.2 Temperature setting 17

3.3 pH/ORP zero, slope and impedance 17

3.3.1 Zero 17

3.3.2 Slope 18

3.3.3 Impedance 18

3.4 Diagnostics 19

3.4.1 Liquid Earth (LE) detection 19

3.4.2 Device state 19

3.4.3 Calibration due 19

3.4.4 Last calibrated 19

3.4.5 Predictive maintenance 19

3.4.6 Sensor wellness 20

3.4.7 Sensor status 20

3.5 Output setup 21

3.6 Calibration and Commissioning 21

IM 12A06S01-00EN-P

9

4 COMMISSIONING OF pH/ORP 22

4.1 Measurement setup 22

4.1.1 Measurement select 22

4.1.2 Temperature settings 22

4.1.3 Temperature compensation 22

4.1.4 Process compensation 23

4.1.5 pH settings 23

4.1.6 ORP settings 24

4.1.7 rH settings 24

4.1.8 Impedance settings 24

4.1.9 Unit conversion 24

4.1.10 Calibration settings for pH/ORP1/ORP2 24

4.2 Communication setup 25

4.3 Error configuration 25

4.4 Logbook configuration 28

5 CALIBRATION OF pH/ORP 29

5.1 Temperature calibration 29

5.2 pH calibration 29

5.2.1 Manual calibration 29

5.2.2 Automatic calibration 30

5.2.3 Sample calibration 30

5.2.4 Fully Automatic calibration 31

5.3 ORP/rH calibration 31

6 OPERATION OF SC (Specific Conductivity) 32

6.1 SA11 quick setup 32

6.2 Measurement setup 32

6.2.1 Parameter setting 32

6.2.2 Temperature setting 32

6.3 Cell constant & polarization 32

6.3.1 Cell constant 32

6.3.2 Polarization 32

6.4 Diagnostics 32

6.4.1 Device state 32

6.4.2 Calibration due 33

6.4.3 Last calibrated 33

6.4.4 Predictive maintenance 33

6.4.5 Sensor wellness 33

6.4.6 Sensor status 34

6.5 Output setup 34

6.6 Calibration and Commissioning 34

IM 12A06S01-00EN-P

10

7 COMMISSIONING OF SC (Specific Conductivity) 35

7.1 Measurement setup 35

7.1.1 Measurement select 35

7.1.2 Temperature settings 35

7.1.3 Temperature compensation 35

7.1.4 Process compensation 35

7.1.5 Concentration 36

7.1.6 USP23 36

7.1.7 SC settings 36

7.1.8 Unit conversion 37

7.1.9 Calibration settings for Conductivity/Resistivity 37

7.2 Communication setup 37

7.3 Error configuration 38

7.4 Logbook configuration 39

8 CALIBRATION OF SC (Specific Conductivity) 40

8.1 Temperature calibration 40

8.2 Cell constant calibration 40

8.2.1 Cell constant (manual) 40

8.2.2 Cell constant (automatic) 40

8.2.3 Sample 41

8.3 Temperature coefficient (TC) 41

9 MAINTENANCE 42

9.1 Periodic maintenance SA11 42

9.2 Periodic maintenance of sensors 42

10 TROUBLESHOOTING 43

10.1 Installation of SA11 43

10.2 Setting of the SA11 43

10.3 Sensor 43

10.4 Application 43

11 APPENDICES 44

11.1 Appendix 1: Factory defaults & setting limits pH 44

11.2 Appendix 2: Buffer tables and matrix compensation pH 46

11.3 Appendix 3: Logbook pH 48

11.4 Appendix 4: Factory defaults & setting limits SC 49

11.5 Appendix 5: Matrix tables and buffer solutions SC 50

11.6 Appendix 6: USP <645> 54

11.7 Appendix 7: Logbook SC 55

IM 12A06S01-00EN-P

11

1 INTRODUCTION AND GENERAL DESCRIPTION

This manual describes how to use SA11 with Yokogawa’s HOST systems and sensors.

Please read carefully this manual and the instruction manual of the relevant HOST system

and sensor before using this SA11 slave device.

The model SA11 Smart Adapter can perform 2 kind of measurements, each measurement

having it’s own specific SA11 model of wich the pH parameter is devided into a model for

conventional pH sensors and a model for differential pH sensors:

1a. pH/ORP (oxidation-reduction potential) for conventional sensors, model SA11-P1;

1b. pH/ORP (oxidation-reduction potential) for differential sensors, model SA11-P2;

2. Contact Conductivity (SC), model SA11-C1.

1.1.Instrument check

Upon delivery, unpack the device carefully and inspect it to ensure that it was not damaged

during shipment. If damage is found, retain the original packing materials (including the outer

box) and then immediately notify the carrier and the relevant Yokogawa sales office.

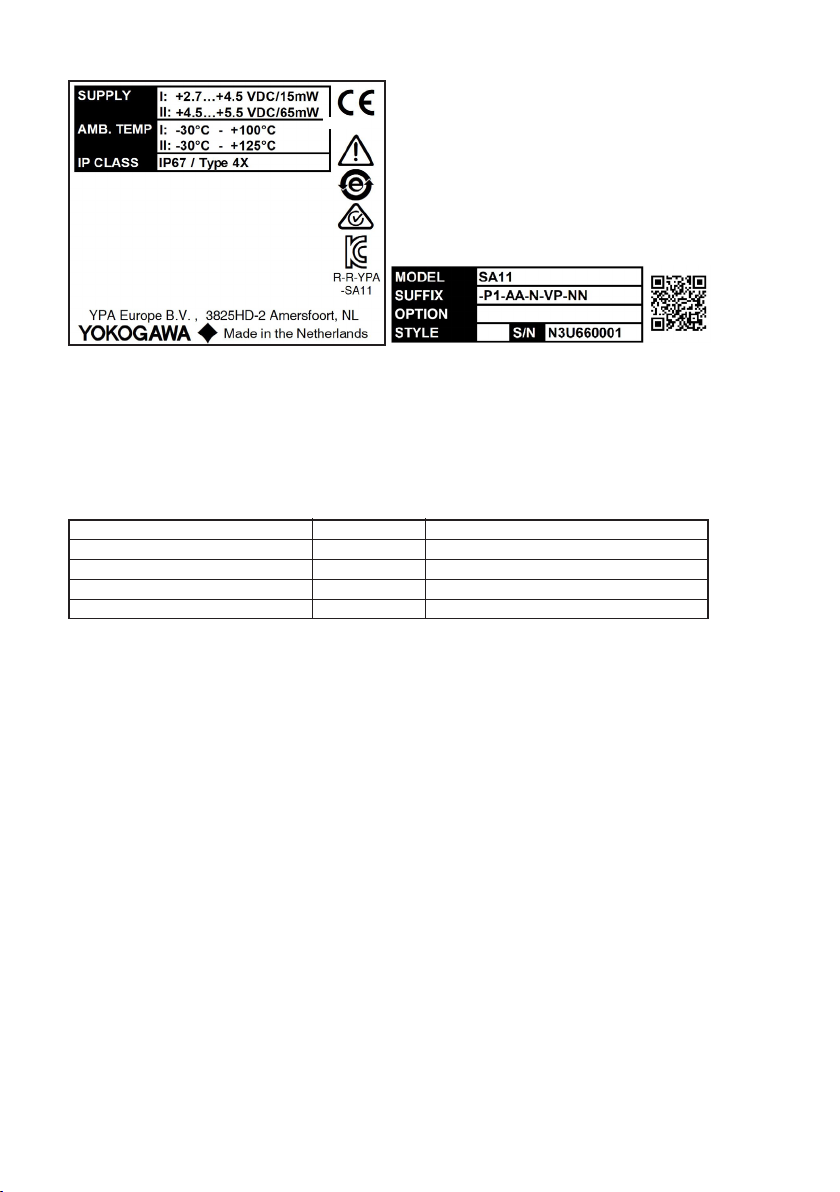

• Checking the model and suffix code

Make sure the model and suffix code on the metallized label affixed to the device housing

are in line with the order. Refer to Section 1.4.

Note: Be sure to apply correct power to the device, as detailed on the label.

CAUTION

The device is packed carefully in a shock absorbing box, nevertheless, the device may be

damaged or broken if subjected to strong shock, such as if the box is dropped. Handle with

care.

• Checking the serial number

The Serial Number is defined by nine (9) alphanumeric characters as follows:

X1X2Y3M4N5N6N7N8N9e.g. N3U100021

X1X2: Production Site

Y3M4: Year/Month code

N5N6N7N8N9: Tracking number

Table 1.1: Production year code

Year Year code Year Year code Year Year code Year Year code

2010 K 2015 R 2020 W 2025 2

2011 L 2016 S 2021 X 2026 3

2012 M 2017 T 2022 Y 2027 4

2013 N 2018 U 2023 Z 2028 5

2014 P 2019 V 2024 1 2029 6

Table 1.2: Production month code

Month Month code Month Month code Month Month code

January 1 May 5 September 9

February 2 June 6 October A

March 3 July 7 November B

April 4 August 8 December C

IM 12A06S01-00EN-P

12

Figure 1.1: Example of label SA11

1.2.Checking the accessories

Make sure that besides the SA11 device the accessories in Table 1.3 are included. Options

are available only if ordered.

Table 1.3: Accessories

Product Name Quantity Remark

SA11 Smart Adapter dust caps 2 pcs/device To prevent dust inside the connectors

Option: Universal mounting set 1 set Option code /UM*

Startup Manual 1 copy Quick startup description

QIS/QIC 1 copy Test certificate

* Option /UM contains Pipe and Wall mounting hardware

Note: Be sure to remove the dust caps before using the device.

1.3.Regulatory Compliance

Safety: IEC 61010-1

EN61010-1

Category based on IEC 61010: I (Note 1)

Pollution degree based on IEC 61010: 2 (Note 2)

Note 1: Installation category, called over-voltage category, specifies impulse withstand

voltage. Equipment with “Category I” is used for connection to circuits in which

measures are taken to limit transient over-voltages to an appropriately low level.

Note 2: Pollution degree indicates the degree of existence of solid, liquid, gas or other

inclusions which may reduce dielectric strength.

EMC: EN61326-1 Class A, Table 2 (For use in industrial locations)

Influence of immunity environment (Criteria A): Output is within

accuracy

EN61326-2-3

AS/NZS CISPR11

KC (registered as R-R-YPA-SA11)

RoHS2: EN 50581

Installation altitude: 2000 m or less

IM 12A06S01-00EN-P

13

CAUTION

The device is packed carefully in a shock absorbing box, nevertheless, the device may be

damaged or broken if subjected to strong shock, such as if the box is dropped. Handle with

care.

CAUTION

The device is a Class A product, and it is designed for use in the industrial environment.

The device however can be used in a laboratory environment too.

WARNING

Do not use an abrasive or organic solvent in cleaning the device.

WARNING

The SA11 contains components that can be damaged by electrostatic discharge.

When servicing this device, please observe proper procedures to prevent such damage.

1.4.Model & Suffix Codes

Model Suffix code Option code Description

SA11 SENCOM Smart Adapter

Measuring -P1 pH/ORP, conventional

Parameter -P2 pH/ORP, differential

-C1 Specific Conductivity

Type -AA General purpose

Region -N Not specified

Conn. type -VS Variopin connector for SENCOM ID-chip

in sensor

Style -NN Always -NN

Option /UM Pipe and wall mounting hardware

1.5.Spare part list

Order no. Product Name Quantity Remark

K1548PQ Universal mounting set 1 set Option /UM

K1548GF O-ring set (5 pieces) 1 set

Option /UM contains Pipe and Wall mounting hardware

Figure 1.2: Positioning of O-ring

IM 12A06S01-00EN-P

14

2 WIRING AND INSTALLATION

Figure 2.1: Installation diagram SA11

2.1 Installation site

The SA11 is weatherproof and can be installed both inside and outside. Select an

installation site that meets the following conditions:

• Mechanical vibrations and shocks are negligible

• No relay switch and power switch are installed close to the device

• There is space mounting the device to the Yokogawa sensor & Yokogawa HOST system

• Not exposed to direct sunlight or severe weather conditions

• Maintenance is possible

• No corrosive atmosphere

• Water Protection: IP67, NEMA Type 4X

2.2 Connecting to the sensor

2.2.1 Direct mounting

The SA11 can be installed directly on top of the Yokogawa labelled sensor by means of the

Variopin connection system. In this case the temperature limit of the device is determined by

the process temperature, limited from -30 up to +100°C / -22 up to +212°F for power supply

+2.7 to +4.5VDC, -30 up to +125°C / -22 up to +257°F for power supply +4.5 to +5.5VDC.

Figure 2.2: Example of direct mounting of SA11 to sensor

CAUTION

Place the Variopin connectors securely to guarantee IP67.

YPA Europe

Made in the Netherlands 3825HD-2

BA11

ACTIVE JUNCTION BOX

BUS SENSOR CONNECTIONS

IN OUT J1 J2 J3 J4

WU11-M9-**-CN-S

Modbus Host

e.g. FLXA402

WU11-M9-**-WP-S

WU11-M9-**-WP-S

max. 100m (328ft)

max. 100m

(328ft)

max. 100m

(328ft)

Suffix -C-AA-M9

Serial# N3T400171

Power +2.7. +5.5VDC/30mW

T amb. -20.. + 55ºC

IP Type 4X / IP66 2018

Read IM

12B06W03-01E-E

IM 12A06S01-00EN-P

15

2.2.2 Cable mounting

When there is less room to install the SA11 on top of the Yokogawa labelled sensor or

when the process conditions are higher than +100°C (for power supply +2.7 to +4.5VDC) or

+125ºC (for power supply +4.5 to +5.5VDC), an alternative mounting method is to install the

SA11 using the optional wall/pipe mounting hardware. The SA11 in this case is connected

to the sensor using the dedicated extension cable model WE10 with a fixed length of 2.95

meter. The ambient temperature limit of the device has to be within -30 to +55°C.

Figure 2.3: Example of cable mounting of SA11 to sensor

CAUTION

Place the Variopin connectors securely to guarantee IP67. When securing the Variopin

connectors, be sure no moisture is encaptulated to garantee isolation in between the

individual contacts. Variopin connector can be cleaned with iso-propanol. Be sure it is dry

before re-connecting.

Note: Use the correct Variopin cable. For correct measurement without loss of specification

the SA11-P1 must be used with WE10-H-D-003-V1, all other types must be used

with WE10-H-D-003-V2.

2.3 Wiring to the HOST system

2.3.1 Wired connection

The Yokogawa HOST system is connected to the SA11 using the WU11 type S

interconnection cable with at one end wired terminals and on the other end a M9 connector.

This cable is specified for reliable transfer of digital signals, and especially designed to

be installed in a heavy industrial environment. The double shielded cable will protect the

connected devices for interference from high voltages and currents which are present

on other cables. The cable is specified to be used in IP67 applications, allowing it to be

submerged as a whole. The WU11 type S cable is available length up to a maximum of 100

meter.

2.3.2 Connection in daisy chain concept

The Yokogawa HOST system model FLXA402 can be connected to maximum five (5) SA11

devices. In case of more than two (2) SA11 devices connected, the BA11 Active Junction

Box must be used. Connection in between the FLXA402 and BA11 is done by using the

WU11 type S interconnection cable with at one end wired terminals and on the other end

a M9 connector. Connection in between the BA11 and the SA11 is done using the WU11

type S interconnection cable with at both ends a M9 connector. In both cases the maximum

length has to be within 100 meter.

IM 12A06S01-00EN-P

16

2.3.3 Wireless connection

In laboratory environments the HOST Fieldmate system can be connected to the SA11

using the Yokogawa Bluetooth device model IB100. Interconnection in between the IB100

and SA11 is done using the WU11 type S interconnection cable with at both ends a M9

connector. The wireless communication in between the Fieldmate system and IB100 is

limited to a distance of 10 meter.

Grounding

The measuring system must always be

connected to a class D ground (a ground

resistance of 100 Ohm or less), preferably

done at the HOST side. To protect the

SA11 device against interference, such as

electromagnetic noise or common mode, all

wires in WU11 type -S cable are connected

at HOST. This makes the housing of the

SA11 grounded. For correct measurement

without loss of specifications, it is strongly

recommended to ensure that the process

liquid is grounded. Figure 2.4 shows the

connection diagram in case without/UM

option.

However, in case that there is different

potential between Ground at HOST side and

Ground which the housing of the SA11 is

connected, figure 2.5 shows the example

of the installation. To prevent ground loop

by this different potentials it is necessary to

disconnect one of the ground references.

This can be done at the HOST side by

disconnecting the wire #82 of the WU11 type

S cable. Please connect #82 to NC terminal

on the SENCOM SA module when SA11 is

connected to FLXA402. Please be sure to

insulate contact pin of #82 wire from terminals

and metal housing, when SA11 is connected

to other host. The SA11 device must then

be installed using the optional pipe and wall

mounting hardware (/UM) with a ground wire

connected in between the ground terminal

of the mounting bracket and the ground

reference of the process.

Alternate way to prevent ground loop is

to isolate the SA11 & mounting plate from

ground 2 & keep the terminal 82 connected.

Remark: For the installation shown in Figure

2.5, in case the ground references at the

HOST side (Ground 1) and process side

(Ground 2) have no potential difference the

Host

WU11

(max 10m)

Ground

WE10

(max 3m)

SA11/UM

Sensor

Liquid

IB100

Figure 2.6: Installation example

SA11 & IB100 to prevent interference

Ground 1

#82

Host

WU11

(max 100m)

Ground 2

WE10

(max 3m)

SA11/UM

Sensor

Liquid

Figure 2.5: Typical installation example

to prevent ground loop

Host

Ground 1

Sensor

SA11

WU11

(max 100m)

Liquid

Ground 2

Figure 2.4: Typical installation of

SA11 to host

IM 12A06S01-00EN-P

17

shield wire of the WU11 type -S cable (wire #82) can stay connected to the (pre-defined)

ground terminal at the HOST.

In combination with Host who does not have grouding terminal to still meet the statutory

regulations it is necessary to ground either the SA11 enclosure (e.g. by using the option /

UM) or ground the shield of the cable. An example is shown in figure 2.6.

Operation

Select a YOKOGAWA parameter specific sensor equipped with an ID-chip which is suitable

for the process. When all wiring is completed, turn on the power of the HOST system. Part

of the setup of the SA11 will be done automatically by reading the content of the ID-chip of

the sensor. These are sensor characteristics, factory calibration data, customer calibration

data, diagnostics and loggings of calibration and events. For details refer to the SA11 Smart

Adapter User’s Manual. Other setups have to be done by the YOKOGAWA HOST system,

for details see the belonging User’s Manual. If the system is configured incorrectly, an error

indicator may be displayed, or the measurement values displayed may be incorrect. Refer to

the User Manual of the HOST system how to check the initial settings and change them to

suit your purpose.

3 OPERATION OF pH/ORP

3.1 SA11 quick setup

Select a Yokogawa pH/ORP electrode equipped with an ID-chip which is suitable for the

process. When connected to the SA11 and powered, part of the setup of the SA11 will be

done automatically by reading the content of the ID-chip of the sensor. These are sensor

characteristics, factory calibration data, customer calibration data, diagnostics and loggings

of calibration and events. See section 4 and 5 for details.

Other setups have to be done by the Yokogawa HOST system, for details see the belonging

User’s Manual.

3.2 Measurement setup

3.2.1 Parameter setting

The SA11 measures and calculates process parameters, for details see section 4.

The suitable measurement parameter(s) for display and process control can be set by the

Yokogawa HOST system, for details see the belonging User’s Manual.

3.2.2 Temperature setting

The SA11 measures process temperature in Celsius (ºC) or Fahrenheit (ºF). Setup of the

temperature unit is done by the Yokogawa HOST system, for details see the belonging

User’s Manual.

3.3 pH/ORP zero, slope and impedance

3.3.1 Zero

The ZERO is the calibrated sensor offset in mV. Theoretically, the sensor reads 0 mV in a

buffer solution of pH7. The ZERO value indicates the condition of the sensor. The trend of

ZERO drift of the sensor is used to predict the lifetime of the sensor.

ZERO can also be displayed in pH units and then it represents the pH value where the

sensor output is 0 mV at 25ºC. Settings can be done with the Yokogawa HOST system, for

details see the belonging User’s Manual.

IM 12A06S01-00EN-P

18

3.3.2 Slope

The SLOPE is the calibrated efficiency of the sensor unit as a percentage of the theoretical

slope of the sensor unit. The theoretical slope follows the NERNST equation and is

59.16 mV/pH (at 25ºC). The SLOPE can be calibrated only after a two- or a three point

calibration in buffer solutions with a different pH value. A low slope indicates that the sensor

is not clean or is faulty.

The SLOPE can also be displayed as mV/pH at 25ºC. Settings can be done with the

Yokogawa HOST system, for details see the belonging User’s Manual.

Figure 3.1: Zero/slope example

3.3.3 Impedance

The SA11 can measure the condition of the electrodes connected. This is done by

measuring the electrical resistance, and this can be either high-ohmic or low-ohmic.

If the impedance measurement is set as high-ohmic, the measurement is used for glass

break detection. The detection limit is set automatically by the sensor characteristics.

In case the impedance measurement is set as low-ohmic, the measurement is used for

fouling and dry fall detection. Detection limits to be set by Yokogawa HOST system.

The SA11 impedance measurement depends on the device type and connected sensor.

• SA11-P1 type in combination with a pH sensor with Liquid Earth (LE) element:

The SA11 measures both the electrical resistance of the high-ohmic glass membrane

electrode and the electrical resistance of the low-ohmic reference electrode liquid

junction. The liquid junction forms the electrolytic contact between the liquid earth and the

reference electrode. It must be kept clean and filled with conductive electrolyte otherwise

the measurement will suffer from instability, drift and measuring errors.

• SA11-P1 type in combination with a pH sensor without Liquid Earth element:

The SA11 measures only the electrical resistance of the high-ohmic glass membrane

electrode.

• SA11-P2 type in combination with a pH sensor with Liquid Earth element:

The SA11 measures the electrical resistance of the two high-ohmic glass membrane

electrodes.

In cases where a Liquid Earth is suitable for ORP measurement, the impedance value

is based upon the electrical resistance of the low-ohmic reference. For an ORP-pH

compensated measurement the impedance value is based upon the electrical resistance of

the (high-ohmic) glass membrane reference.

pH14

pH0

pH7, 0mV

Theoretical value

+mV

-mV Calibration curve (slope)

Zero

F0410.ai

IM 12A06S01-00EN-P

19

3.4 Diagnostics

3.4.1 Liquid Earth (LE) detection

If a Yokogawa sensor with ID-chip is connected to a SA11-P1 type, the sensor

characteristics explains if LE element is available or not. If available, the SA11 will activate

the LE detection. If LE wiring is broken, an error will be flagged. If a Yokogawa sensor

with ID-chip is connected to a SA11-P2 type, the LE element is always available. The LE

detection is active and if LE wiring is broken an error will be flagged.

3.4.2 Device state

The operating mode of the SA11 is reflecting the device state. Except from the standard

operating mode there are four other modes:

• Sleep mode (all calculations disabled)

• Calibration

• HOLD

• Safely remove (this is not a function of Yokogawa HOST systems)

3.4.3 Calibration due

Calibration due is the date when the calibration must be done next according to the settings

of the calibration interval. The calibration intervals are set by the Yokogawa HOST system,

for details see the belonging User’s Manual.

3.4.4 Last calibrated

The last calibrated is the date on which the last sensor calibration was performed. For ZERO

the displayed value is date of this last calibration. For SLOPE the displayed value is the date

that the last 2-point calibration is executed.

3.4.5 Predictive maintenance

There are two kinds of predictive maintenance:

• Predictive sensor maintenance, which predicts the date when the sensor will need

recalibrating for maintaining measurement accuracy. The function checks the low-ohmic

reference impedance every 24 hours. The function predicts the date when the reference

impedance will cross the upper or lower limits set by the Yokogawa HOST system, and

indicates the date and its reliability status. The date is predicted based on the intersection

point of the upper or lower limits and the extrapolated line of the values obtained by the

least squares method.

Figure 3.2: Predictive sensor maintenance date

Day

Value Lower limit

Upper limit

Current

date

Projected

maintenance date F0310.ai

IM 12A06S01-00EN-P

20

• Predictive sensor replacement, which predicts the date when the sensor will need

replacement. The date is based on the pH ZERO and pH SLOPE on each calibration, and

the measured low-ohmic reference impedance. The date is predicted based on the best

status of correlation in those three parameters. If some parameters have the same status,

the nearest date is selected. The function indicates the date and its reliability status.

3.4.6 Sensor wellness

The SA11 can calculate the performance status of the sensor connected. The calculated

result depends on user programmable settings done in the Yokogawa HOST system, and

the sensor diagnostics data stored in the ID-chip of the sensor.

When a sensor is replaced or exchanged, a reset of the wellness data is not necessary. If a

user wants to reset this data anyhow, this is possible by the Yokogawa HOST system. For

details see the belonging User’s Manual.

There are seven (7) different wellness statuses for pH:

• ZERO

• SLOPE

• IMP1

• IMP2

• Progress time

This is the time in between 0 and actual operating hours of the sensor.

• Heat cycle

This is a counter which counts the settable temperature step changes (up or down) of a

sensor.

• Total

This state indicates the worst wellness state of those activated.

Each wellness status can be set ON or OFF. If activated, the status is measured as a ratio of

the actual value against the calculated value obtained from settings of lower limit and upper

limit. For limit setting see Appendix 1. The status is indicated as a number in between 0

(bad) and 4 (good).

3.4.7 Sensor status

The SA11 monitors some process conditions of the connected sensor:

•Maximum temperature exposed, which is automatically updated every time a higher

process temperature is measured.

• High temperature 1/High temperature 2, which is the total time at which the sensor

is exposed above the corresponding limits, set by the Yokogawa HOST system. The last

date and time (the end of high-temperature condition) is stored.

• Sterilization, which reflects the number of times at which the temperature remains above

the preset value for at least the prescribed time period set by the Yokogawa HOST

system.

Other manuals for SA11

1

Table of contents

Other YOKOGAWA Adapter manuals

YOKOGAWA

YOKOGAWA ZR22P User manual

YOKOGAWA

YOKOGAWA 772075 User manual

YOKOGAWA

YOKOGAWA SA11 Installation and operation manual

YOKOGAWA

YOKOGAWA 98031 User manual

YOKOGAWA

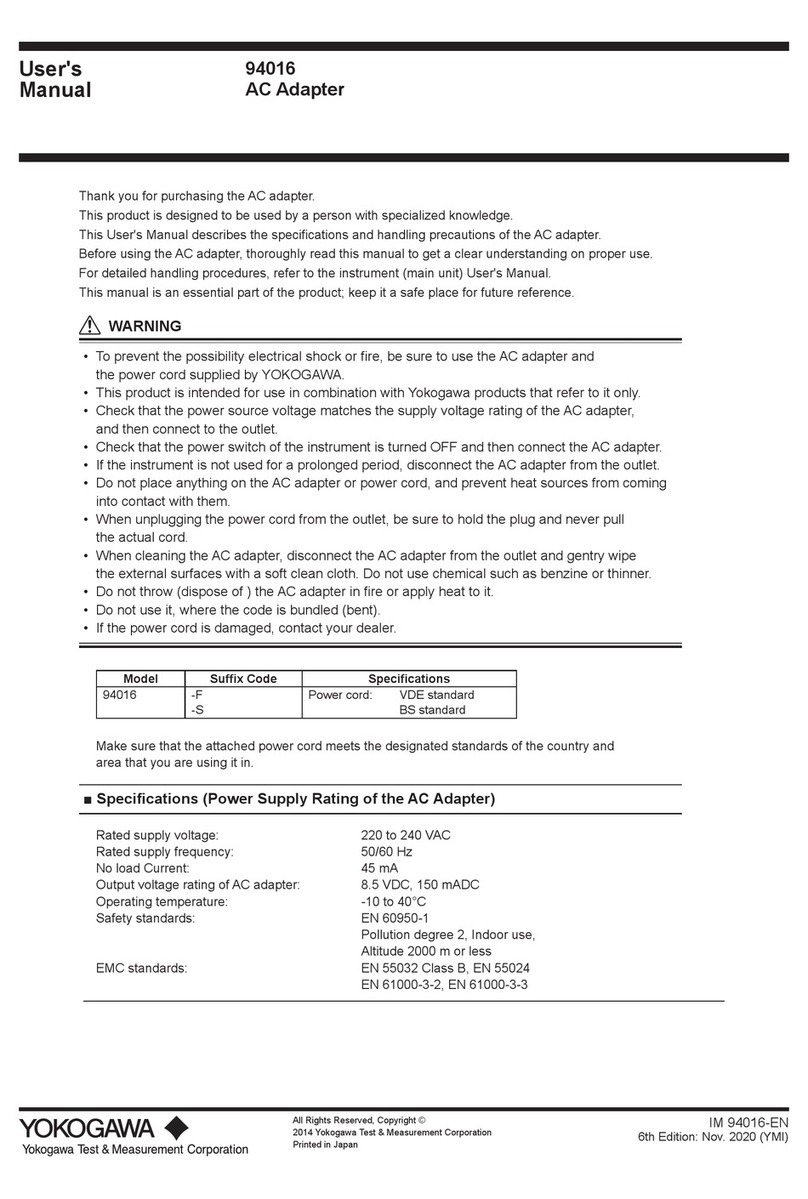

YOKOGAWA 94016 Series User manual

YOKOGAWA

YOKOGAWA 761953 User manual

YOKOGAWA

YOKOGAWA 720921 User manual

YOKOGAWA

YOKOGAWA LE-0309ADSP12V300 User manual

YOKOGAWA

YOKOGAWA 94016 User manual