Operating Procedure

1. Enter the appropriate settings on the measuring instrument being used to accommodate the

output from the probe.

2. Connect measuring leads (758917, sold separately) to the probe's output terminals and the

measuring instrument. The connection method diers depending on the measuring instrument

being used. See your instrument's user's manual for the procedure. If the connector on the

measuring leads cannot be connected to the input terminals on the measuring instrument, use

a fork terminal (758921: sold separately) or other adapter.

Example • For a digital power meter, connect a lead from the red output terminal (+) to

the current input I terminal, and from the black output terminal (-) to the current

± terminal.

• For a digital multimeter, connect a lead from the red output terminal (+) to the

A terminal, and from the black output terminal (-) to the Lo terminal.

3. Squeeze the jaws to open the clamps, then position the conductor inside the feed-through

hole. Hold the probe so that the conductor is as closely in the center of the feed through hole

as possible.

4. Release the clamp lever to close the clamps. Steps 3 and 4 is called clamping.

5. Read the measured values on the measuring instrument. Calculate the current owing

through the conductor using an input/output ratio of 1000:1.

Example: Given that 150.0 mA is owing from the probe's output terminal,

current = 150.0 mA × 1000 = 150.0 A.

Note

• Close the clamp completely before taking measurements. Errors can occur If any foreign

objects or particles become trapped between the jaws.

• Only perform measurements on conductors in which the current is flowing in only one

direction. The instrument cannot correctly measure earth-shielded conductors or parallel

conductors with current owing in both directions.

• To reduce errors, use a measuring instrument with an internal impedance less than or equal to 1Ω.

• If DC current is superimposed on an AC current being measured, the output signal from the

clamp will become distorted and measurements will be inaccurate.

• When measuring phase dierence in voltage and current using an instrument such as a digital

power meter, make sure that the current ows in the same direction as the arrows on the probe.

The phase dierence can be correctly measured by positioning the clamp so that current ows

from the front side (name plate) to the reverse side (in the direction shown by the arrows on the jaws).

• Avoid locations with extremely strong external magnetic fields (other than the conductor

under test) as they may cause measurement errors.

5. Specications

Safety Standards Complying standard: EN 61010-1 & EN IEC 61010-2-032

Instrument with double insulation or reinforced insulation between primary, secondary

and outer case parts.

Operating voltage: 600 V Measurement category III1, Pollution degree 22.

Operating voltage: 300 V Measurement category IV1, Pollution degree 22.

Electromagnetic compatibility Complying standard: EN61326-1

Environmental standards

3

EU RoHS Directive compliant

Current Range AC 0.001 to 1200 Arms. However, for 1000 to 1200 Arms, refer to the Maximum Current

Current Transformation Ratio 1000:1

Output Signal AC 1 mA/A (or 1 A/1000 A)

Accuracy and Phase shift (at Reference Conditions4)

PrimaryCurrentI 1≤I<100mA 0.1≤I<1A 1≤I<10A 10≤I<100A 100≤I≤1200A

%accuracyof ≤3%ofrdg+5µA ≤2%ofrdg+3µA ≤1%ofrdg ≤0.5%ofrdg ≤0.3%ofrdg

output signal (rdg: reading of output signal)

Phase shift Notspecied Notspecied ≤2deg ≤1deg ≤0.7 deg

Bandwidth 30 Hz to 5 kHz (error in frequency inuence is added to Accuracy at Reference Conditions).

Crest Factor 6 or less for a 2000 A peak (333 Arms) current or less

Maximum Current For a continuous frequency f of 1 kHz or less, I ≤ 1000 A

For frequencies exceeding 1 kHz, the current that can be allowed to ow continuously

(Ipermanent) is calculated as follows:

Ipermanent = 1000A/f(kHz)

For an input signal of 1000 A < I ≤ 1200 A at 1 kHz, the probe can be used continuously

for a maximum of 40 minutes. Do not perform measurements 20 minutes thereafter

Load Impedance 1 Ω or less

Max. Output Voltage 30 V peak or less (restricted by the output protection circuit).

Working Voltage Max. 600 Vrms

Inuence of Adjacent Conductor When the frequency of the current in an adjacent conductor is 50 Hz, the

inuence on the primary current is 0.5 mA/A or less.

Inuence of Conductor Position in the Jaws 0.1% or less in the output signal for a frequency of 400 Hz or less.

Inuence of Load Impedance r When 1 Ω < r ≤ 5 Ω, under 0.1% of output signal, and phase shift under 0.2 degrees

Inuence of Frequency f5 30 Hz ≤ f < 48 Hz: under 0.5% of output signal

65 Hz < f ≤ 1 kHz: under 1% of output signal

1 kHz < f ≤ 5 kHz: under 2% of output signal

Inuence of Crest Factor Under 1% of output signal, given a crest factor of 6 or less for a 2000 A peak

(333 Arms) current or less

Inuence of DC Current Superimposed on Nominal Current

Under 1% of the output signal, assuming a current of DC 15 A or less.

Operating Temperature –10°C to +50°C

Storage Temperature –40°C to +70°C

Temperature Inuence 0.02%/°C or less of the output signal

Operating Humidity 0 to 90% RH (no condensation) However, if 35°C is exceeded, humidity will impair the

primary functionality (by a factor of 0.5% RH/°C)

Inuence of Humidity Under 0.1% of the output signal given 10% RH ≤ Humidity < 20% RH or

75% RH < Humidity ≤ 90% RH

Operating Altitude 2000 m or less above sea level

Installation Indoor use

Max. Jaws Opening 53 mm (open jaws height: 139 mm (W))

External Dimensions Approx. 111(W) x 216(H) x 45(D) mm

Weight Approx. 620g.

Output Safety jacks (Φ4 mm)

1 This instrument is a measurement category III (600V) product. In this case do not use it for measurement

category IV measurements. This instrument is a measurement category IV (300V) product.

Measurement category O applies to measurement of other types of circuits that are not directly connected

to a main power source.

Measurement Category II applies to electrical equipment that is powered through a xed installation, such

as a wall outlet wired to a distribution board, and to measurement performed on such wiring.

Measurement category III applies to measurement of facility circuits, such as distribution boards and

circuit breakers.

Measurement category IV applies to measurement of power source circuits, such as entrance cables to

buildings and cable systems, for low-voltage installations.

2 Pollution degree describes the degree to which a solid, liquid, or gas which deteriorates dielectric strength

or surface resistivity is adhering.

Pollution Degree 2 applies to the normal indoor atmosphere. Normally, only non-conductive pollution

occurs. Occasionally, however, temporary conductivity caused by condensation must be expected.

3 For conformity to environmental regulations and/or standards other than EU, contact your nearest

YOKOGAWA oce (PIM 113-01Z2).

4 Reference Conditions

Temperature: 23 °C±3°C Humidity: 20 to 75% RH External magnetic eld < 40 A/m

No AC magnetic eld Conductor centered in jaws Load impedance ≤ 1 Ω (≤ 1 VA)

No inuence of current owing in adjacent conductors

When the primary current is sinusoidal, the sinusoidal conditions are: frequency; 48 to 65 Hz, distortion

factor < 1%, no DC component

5 There is no frequency inuence in the range 48 Hz ≤ f ≤ 65 Hz.

IM 751552-01E 2/2

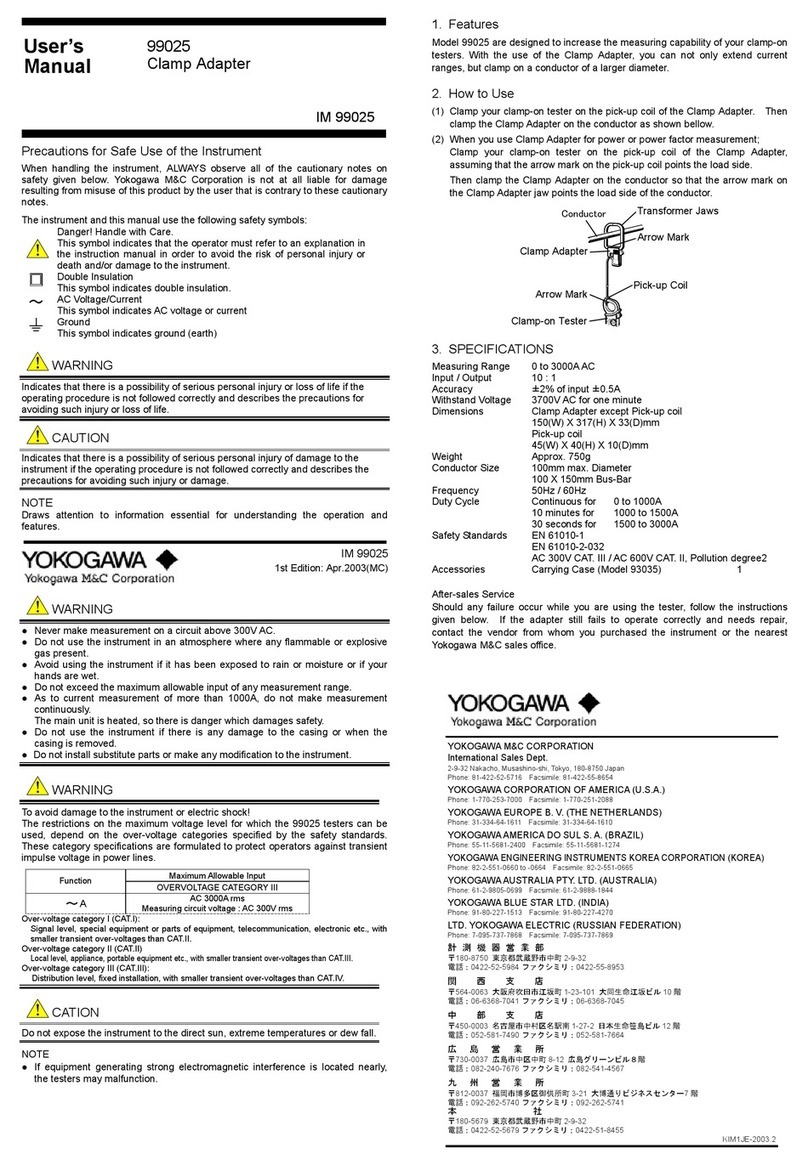

99

111

101

52

216

43.5

31

35

45

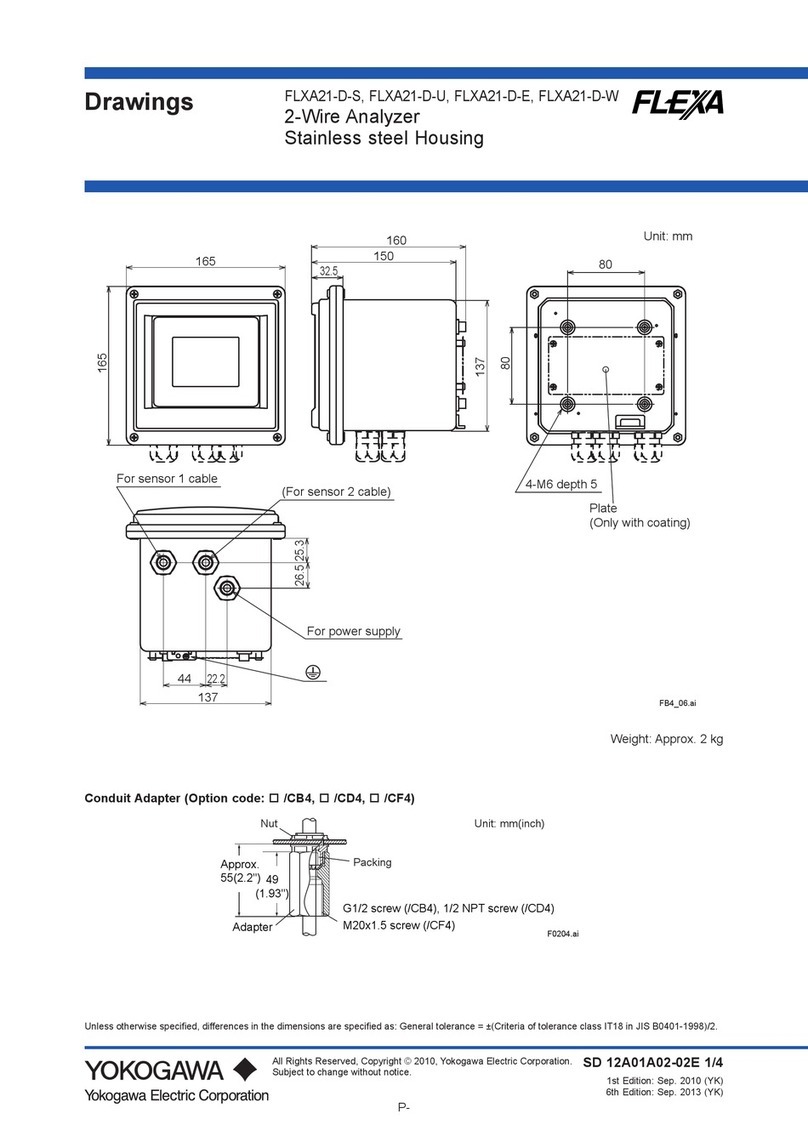

External Dimensions (Units: mm)

6. Maintenance

• Note the following when cleaning the probe.

• Do not clean the probe while clamped to a conductor. Likewise, do not clean while

connected to a measuring instrument.

• Do not allow water to contact the jaws.

• Keep the metal surfaces of the iron cores, which are exposed when the clamp is opened, clean.

If dust accumulates, wipe with a clean dry cloth. To prevent rust, wipe metal surfaces with oil from

time to time. Avoid getting oil on non-metallic surfaces. Use only high quality, low-viscosity machine

oil such as sewing machine oil.

• This product undergoes a 100% inspection at the time of shipment. If any layers of the core

come apart slightly during shipment, this will not aect the functioning of the product.

The metal surfaces of the iron

cores are exposed when the

clamp is opened (4 locations).

Metal surfaces

7. Servicing

If you encounter any problems during use, or if the instrument does not appear to be operating

normally, contact your dealer or nearest YOKOGAWA representative.

8. Appendix

Waste Electrical and Electronic Equipment (WEEE)

(EU WEEE Directive valid only in the EEA* and UK WEEE Regulation in the UK)

This product complies with the WEEE marking requirement. This marking indicates that

you must not discard this electrical/electronic product in domestic household waste.

When disposing of products in the EEA or UK, contact your local Yokogawa oce in

the EEA or UK respectively.

* EEA: European Economic Area

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test & Measurement

Corporation for this product in the EEA. To contact Yokogawa Europe B.V., see the separate list of

worldwide contacts, PIM 113-01Z2.

Disposal

When disposing of YOKOGAWA products, follow the laws and ordinances of the country or region

where the products will be disposed of.