Safety3/3

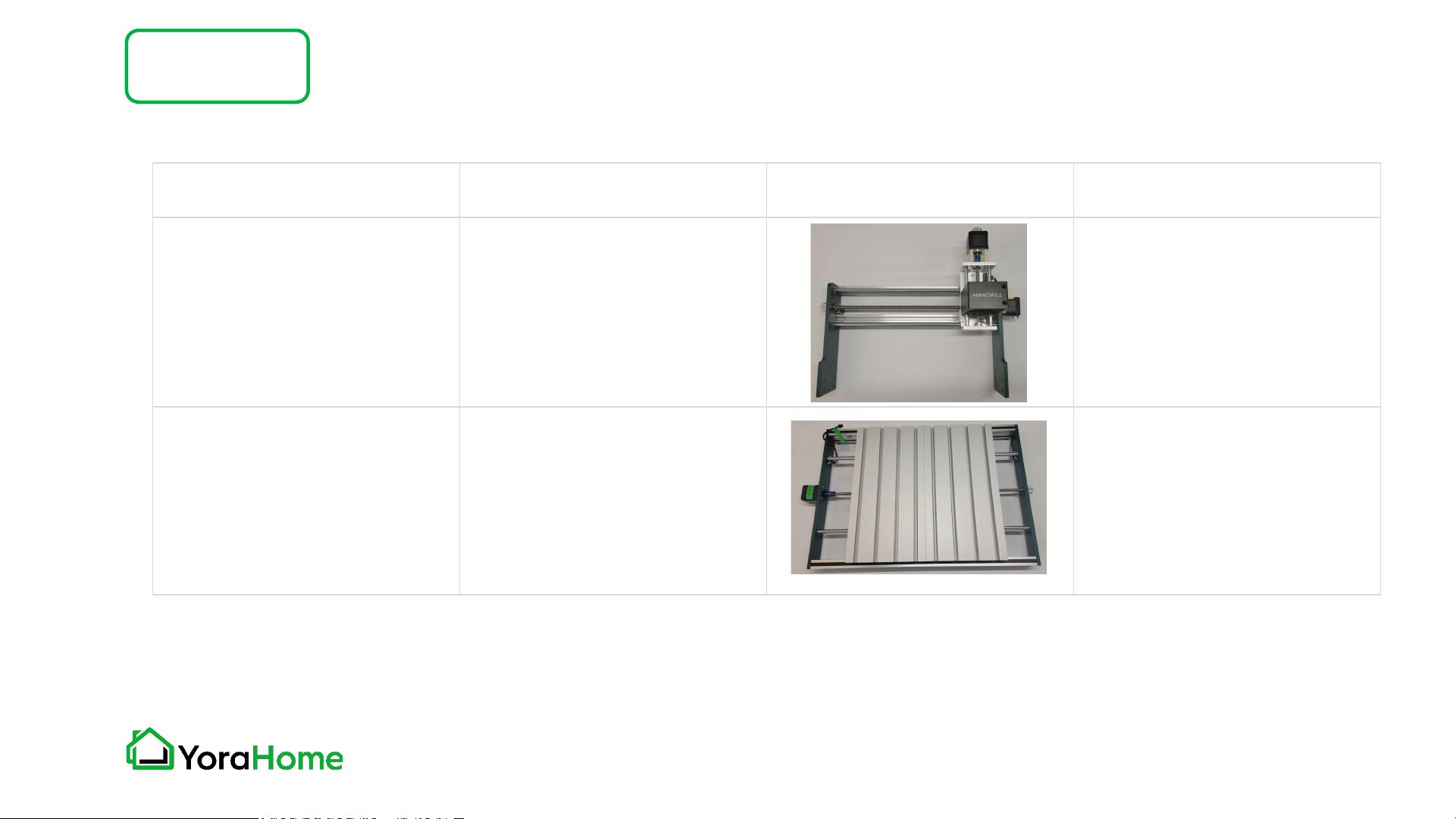

➔Always secure workpiece to spoil board using clamps or double-sided tape. Never hold

workpiece down by hand while operating.

➔Make sure workpiece is free from nails or other foreign objects.

➔After installing a bit, make sure collet is securely tightened. An unsecured bit may fly loose

from the collet and cause injury.

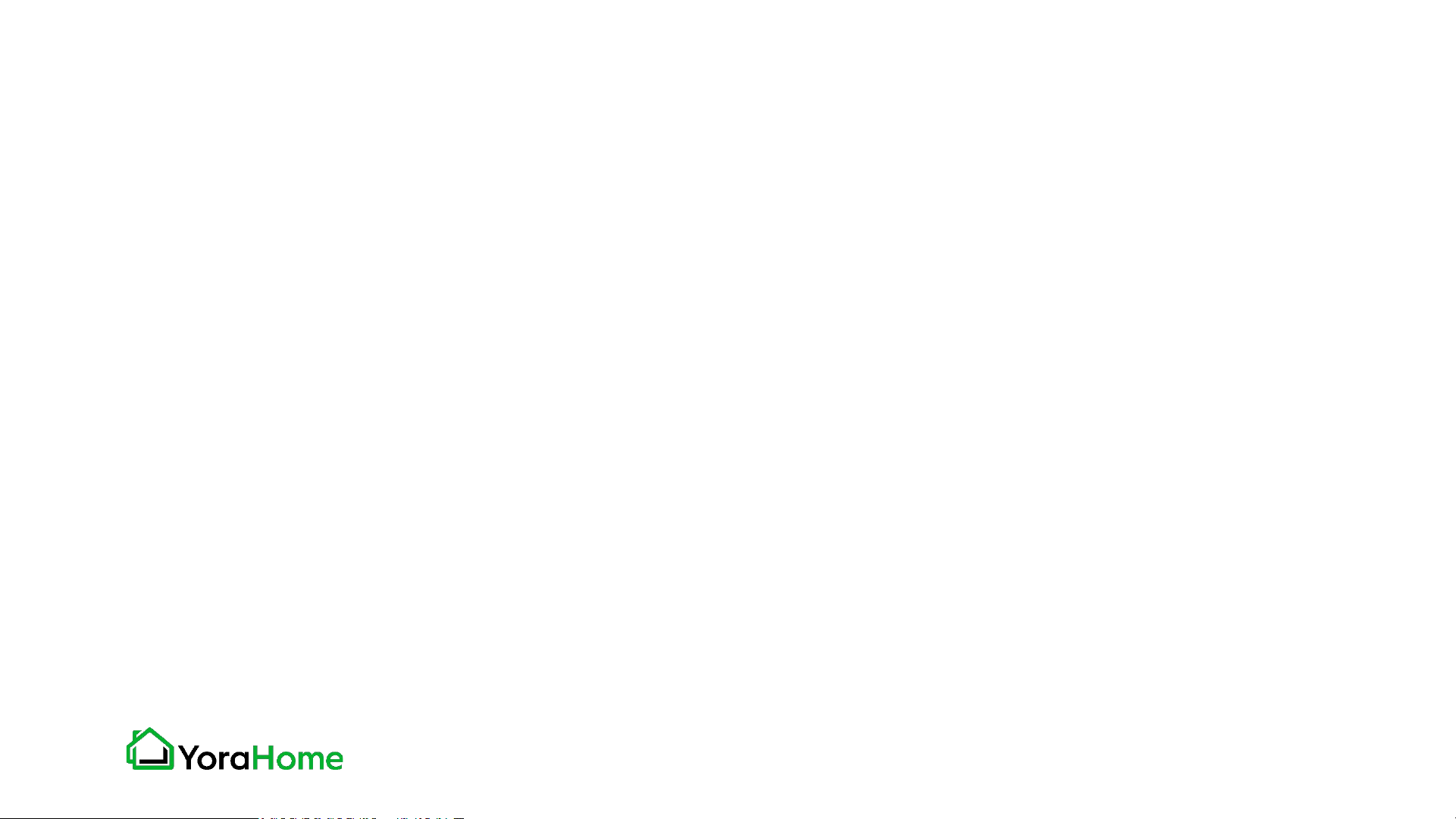

➔The Mandrill CNC router is intended for carving and cutting wood, acrylics, plastics and soft

metal, etc. Do not use it to cut hard metals.

➔Be within reach of the Emergency Stop or pause button when the machine is in operation. In

the event of an emergency, or if there are any conditions that may result in injury to yourself or

others, the Mandrill is equipped with an Emergency Stop button on top of the Controller.

When pressed, this button will latch in the Stop position. To reset, twist the red knob

clockwise.