035-13329-001-B-0504

Unitary Products Group 7

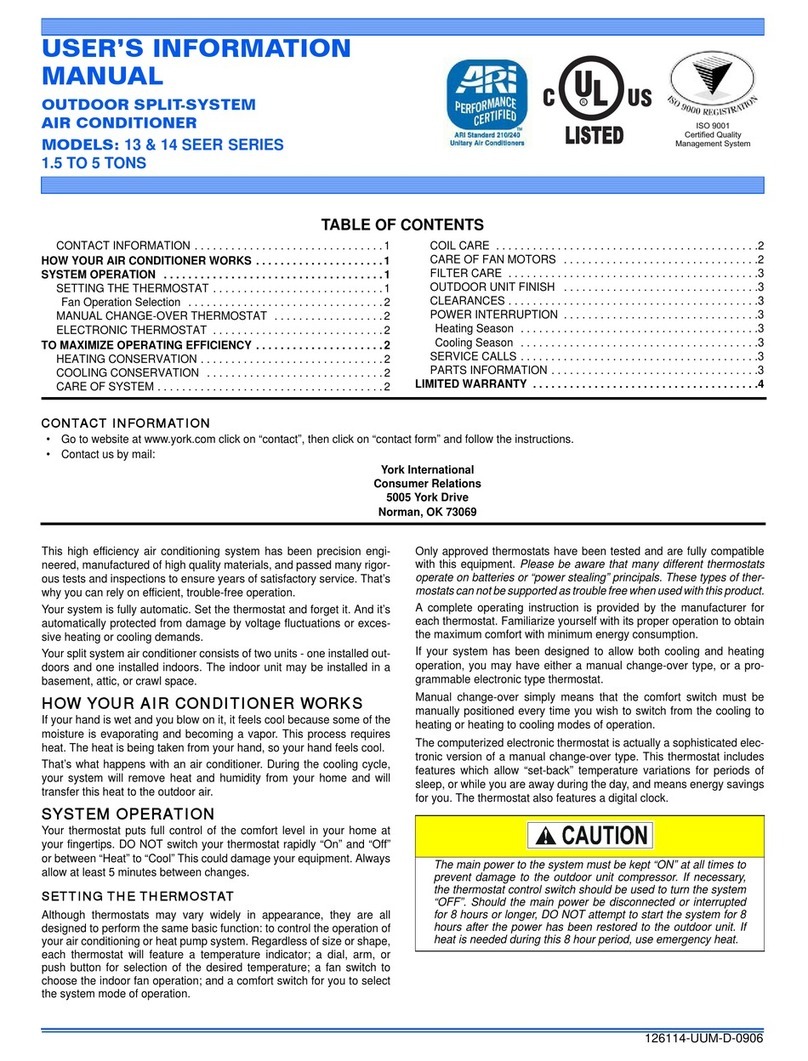

Refer to Figure 6 for typical field wiring and to the appropriate

unit wiring diagram for control circuit and power wiring infor-

mation.

COMPRESSORS

On some units the compressor is mounted on springs which

have been tightened down for shipment only.

After this unit is installed, back out the compressor bolts until

the sleeve clears the top grommet.

.

OPTIONAL ECONOMIZER RAIN HOOD

The following procedure should be used when assembling an

economizer rain hood onto a unit. Refer to Figure 3. The out-

door and return air dampers, damper actuator, the linkage

and all the controls are factory mounted as part of the econo-

mizer option.

All of the hood components, including the filters, the gasket-

ing and the hardware for assembling are located above the

top filter racks within the filter section. The outdoor air sensor

is in the bag of parts located at the bottom of the return air

section.

1. With filter section access panel removed, take out hood

components, filters and sensor described above.

Remove and discard outdoor air opening cover on back

unit (Upper right hand corner).

2. Remove the 1/2" knockout (A) in the units rear panel

(located to the right side of the outdoor air opening).

Insert the two loose wires from inside the unit, into the

1/2" bushing provided. Insert wires and bushing into

knockout. Snap bushing into place.

3. Mount the outdoor air sensor to the rear panel, just

below the knockout described in Step 2. Secure with two

self-drilling screws at dimples (B) provided in the panel.

NOTE: Sensor must be positioned so that the sensing ports

are at the top (louvers pointing downward) and ter-

minal connections to the right.

4. Connect the two wires, indicated in Step 2, to the sensor

as follows:

• Wire #73 to terminal (+)

• Wire #74 to terminal (S)

5. Assemble the LH and RH side plates to the top cover (2

screws each side) to form the hood. Apply gasketing to

the flange surface on each side plate. Extend gasketing

1/4" beyond top and bottom of each flange to insure

adequate corner sealing. Secure this assembly to the

unit back panel (upper right hand corner). First, remove

screw (C) on unit top cover. Then slip flange of hood

cover in under flange of unit top cover, replace screw

(C), engaging hole (E) in hood flange and tighten. Attach

the two side plates to the unit panel by using two self-

drilling screws for each side plate at dimples (D) pro-

vided in the panel.

6. Position fillpiece at bottom of hood, between the two side

plates but do not secure at this time. (Slotted openings

MUST be downward for drainage). After fillpiece is prop-

erly positioned, note where contact is made with the unit

panel.

Remove fillpiece and apply gasket material to this area

to provide a seal. Reposition fillpiece and secure with 2

screws.

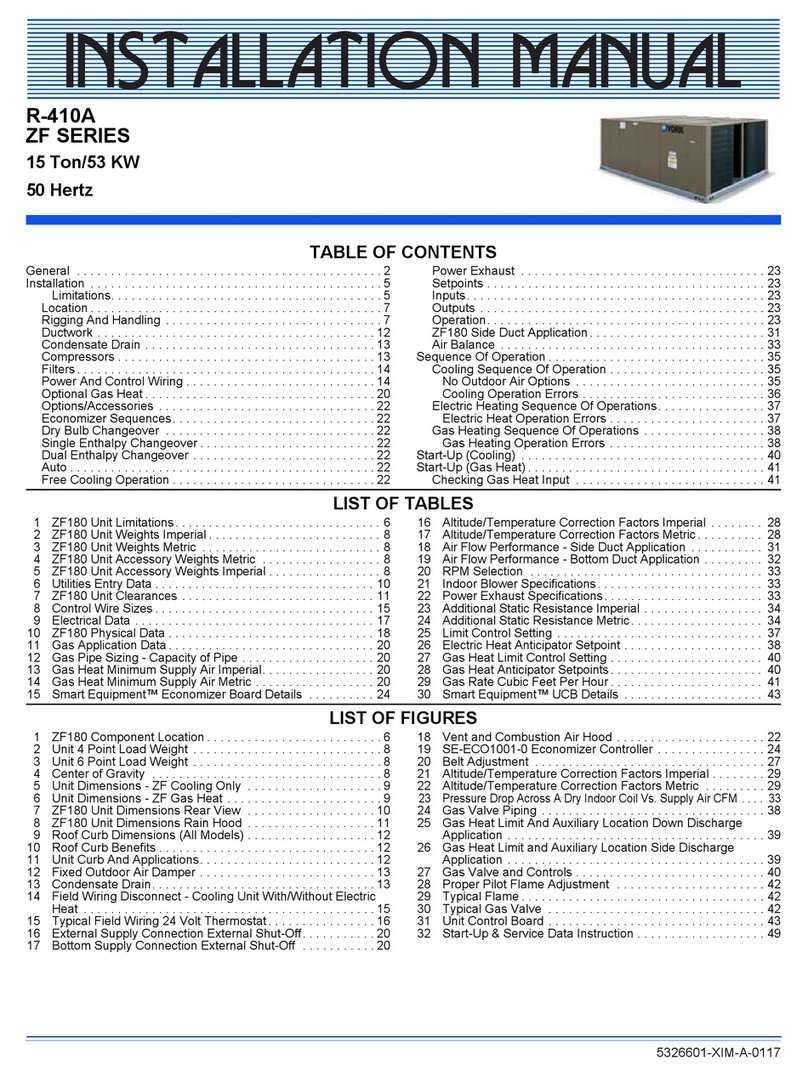

TABLE 1: PHYSICAL DATA

MODELS DHE

036 048 060

EVAPORA-

TOR

BLOWER

CENTRIFUGAL BLOWER (Dia. x Wd.

in.)

FAN MOTOR HP

12 x 10

1.5 12 x 10

1.5 12 x 10

1.5

EVAPORA-

TOR

COIL

ROWS DEEP 4 4 4

FINS PER INCH 13 13 13

FACE AREA (Sq. Ft.) 4.3 5.1 5.1

CONDENSER

FAN PROPELLER DIA. (in.) 24 24 24

FAN MOTOR HP 1/2 1/2 1/2

NOM. CFM TOTAL 4,500 4,200 4,200

CONDENSER

COIL ROWS DEEP 2 2 2

FINS PER INCH 18 18 18

FACE AREA (Sq. Ft.) 17.1 17.1 17.1

AIR FILTERS

(SEE NOTE) QUANTITY PER UNIT(15" x 20" x 1") 2 2 2

QUANTITY PER UNIT(14" X 25" X 1") 1 1 1

TOTAL FACE AREA (sq. ft.) 6.6 6.6 6.6

CHARGE REFRIGERANT 22 (lbs./oz.) 10 / 8 10 / 4 10 / 14

COMPRES-

SOR QUANTITY PER UNIT (HERMETIC-

TYPE) 1 /

RECPT 1 /

RECPT 1 /

RECPT

WEIGHTS (LBS)

Basic Unit

3 Ton 565

4 Ton 610

5 Ton 645

ACCESSORIES / OPTIONS

Electric Heat

(Nominal KW) 5 - 7 KW 18

10 - 15 KW 23

20 - 30 KW 28

Economizer 50

Motorized Outdoor

Air Damper 26

Relief/Fixed

Air Damper 10

Roof Mounting Curb 92

Do Not loosen compressor mounting bolts.