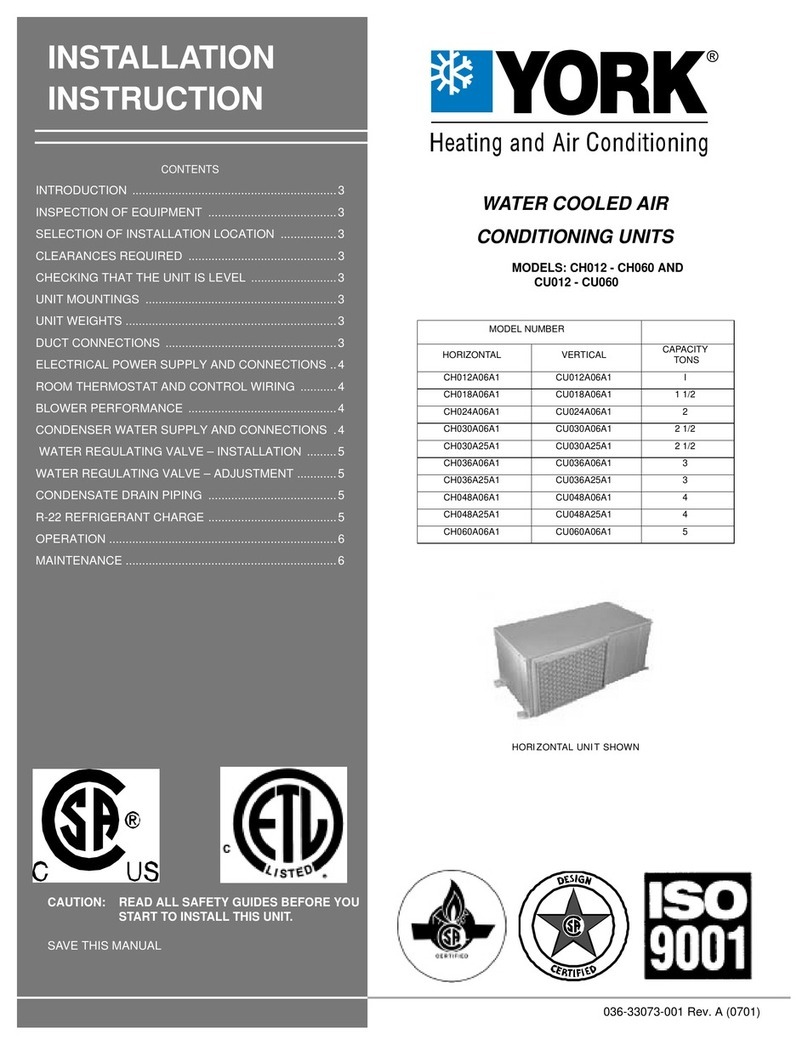

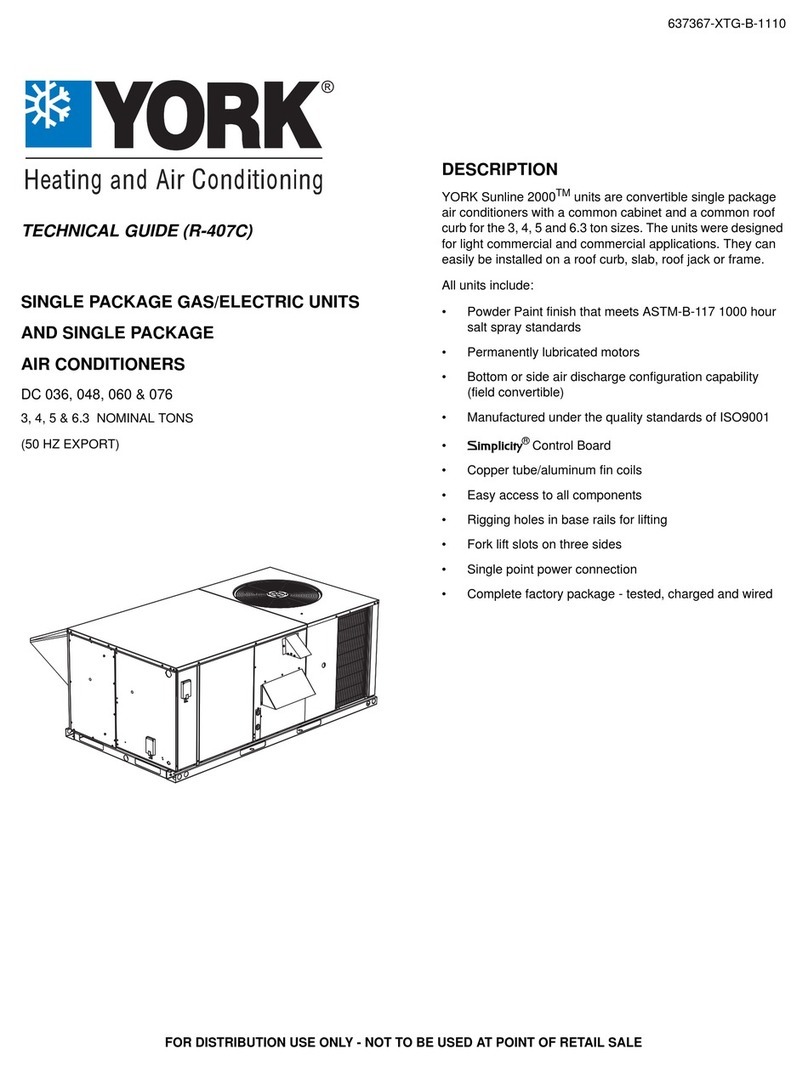

CLEARANCES

All units require certain clearances for proper operation and

service. Refer to Figure 3 for the clearances required for com-

bustion, construction, servicing and proper unit operation.

WARNING:Do not permit overhanging structures or shrubs to

obstruct the condenser air discharge outlet.

DUCT WORK

Theseunitsareadaptable todownflow useaswellasrear sup-

ply and return air duct openings. To convert to downflow, use

the following steps:

1. Remove the duct covers found in the bottom return and

supply air duct openings. There are four (4) screws secur-

ing each duct cover (save these screws to use later).

2. Installtheductcovers,removedinstepone,totherearsup-

ply and return air duct openings. Secure with the four (4)

screws used in step one.

3. Seal the duct covers with silicone caulking.

Downflow units must have an L-shaped supply duct without

any outlets or registers located directly below the supply outlet

of the unit.

Duct work should be designed and sized according to the

methods of the Air Conditioning Contractors of America

(ACCA), as set forth in their Manual D.

A closed return duct system shall be used. This shall not pre-

clude use of economizers or ventilation air intake. Flexible

joints may be used in the supply and return duct work to mini-

mize the transmission of noise.

CAUTION: When fastening duct work to the side duct flanges on

theunit,insertthescrewsthroughtheductflangesonly.

DONOTinsertthescrewsthroughthecasing.Outdoor

duct work must be insulated and waterproofed.

NOTE: Be sure to note supply and return openings.

Refer to Figure 3 for information concerning rear and bottom

supply and return air duct openings.

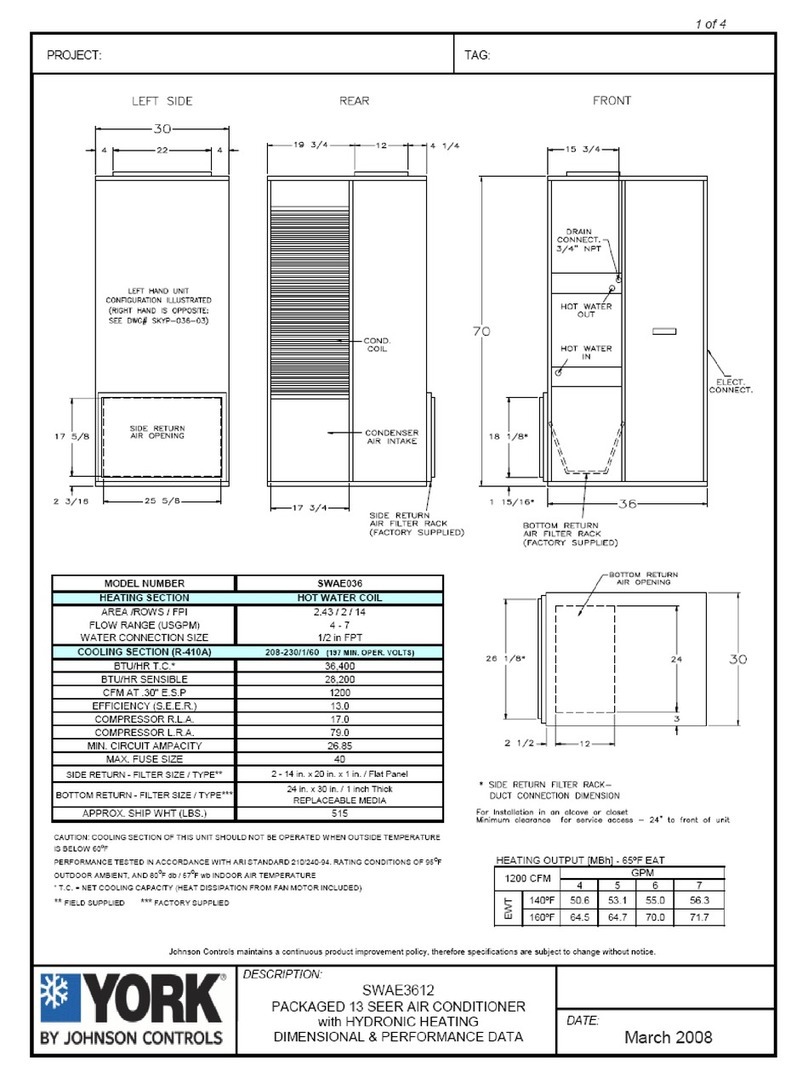

FILTERS

Singlephaseunitsareshippedwithoutafilterandistheresponsi-

bilityoftheinstallerto securea filterin thereturn airductwork or

install a Filter/Frame Kit (1FF0114).

A filter rack and a filters are standard on three phase units.

Filters must always be used and must be kept clean. When fil-

ters become dirt laden, insufficient air will be delivered by the

blower,decreasingyourunitsefficiencyandincreasingoperat-

ing costs and wear-and-tear on the unit and controls.

Filters should be checked monthly especially since this unit

may be used for both heating and cooling.

CONDENSATE DRAIN

Acondensate trap is required to be installed in the condensate

drain. The plumbing must conform to local codes. Use a seal-

ing compound on male pipe threads. Install the condensate

drain line (

34

“ NPTF) to spill into an open drain.

SERVICE ACCESS

Accesstoallserviceablecomponentsisprovidedbythefollow-

ing removable panels:

•Blower service access

•Electrical/filter access

•Compressor service access

Refer to Figure 3 for location of these access panels and mini-

mum clearance.

THERMOSTAT

The room thermostat should be located on an inside wall ap-

proximately 56" above the floor where it will not be subject to

drafts, sun exposure or heat from electrical fixtures or appli-

ances. Follow manufacturer's instructions enclosed with the

thermostatforgeneralinstallationprocedure.Four orfivecolor

coded insulated wires (minimum #18 AWG) should be used to

connect thermostat to unit. See Figure 2.

035-16703-001-A-0202

Unitary Products Group 3

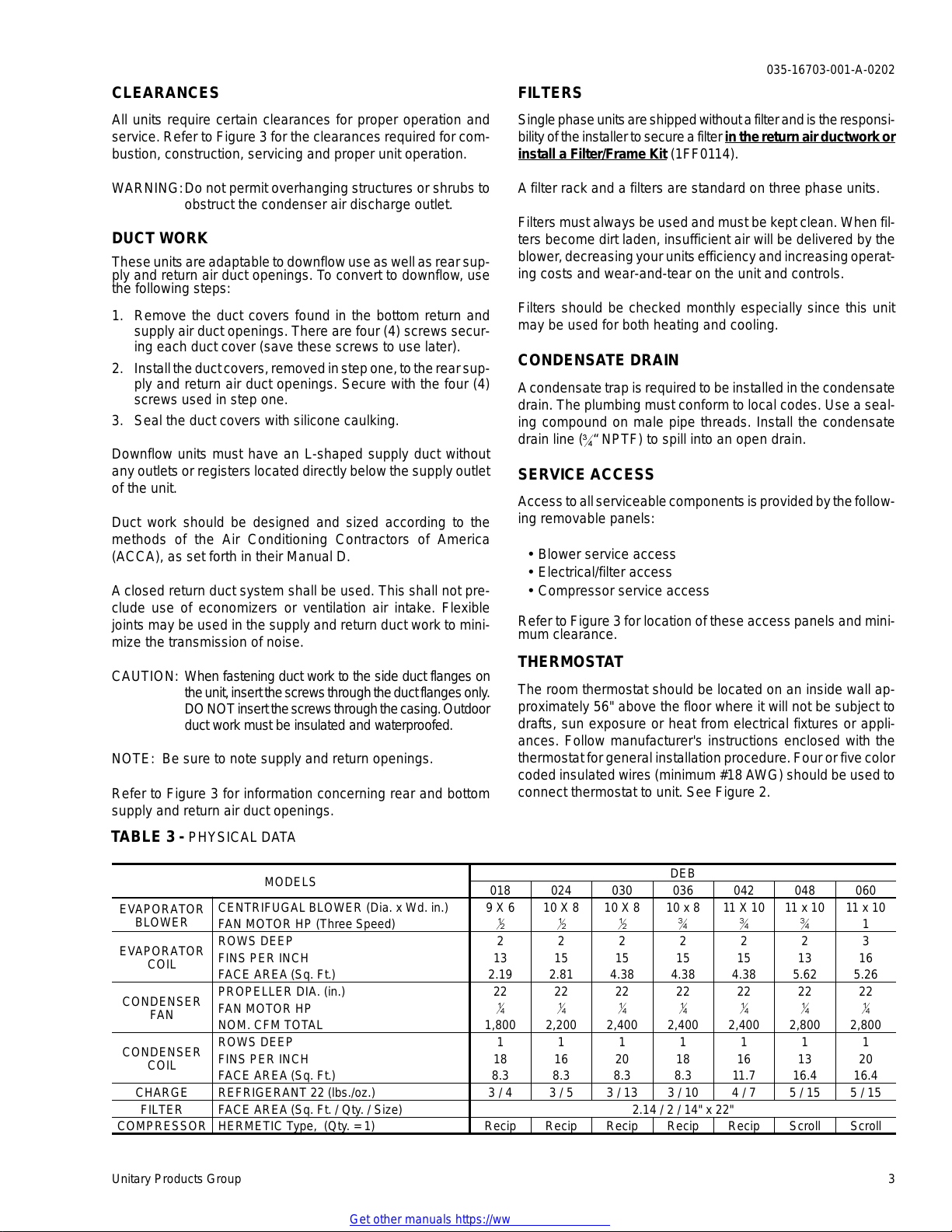

MODELS DEB

018 024 030 036 042 048 060

EVAPORATOR

BLOWER CENTRIFUGAL BLOWER (Dia. x Wd. in.) 9 X 6 10 X 8 10 X 8 10 x 8 11 X 10 11 x 10 11 x 10

FAN MOTOR HP (Three Speed)

121212343434

1

EVAPORATOR

COIL

ROWS DEEP 2222223

FINS PER INCH 13 15 15 15 15 13 16

FACE AREA (Sq. Ft.) 2.19 2.81 4.38 4.38 4.38 5.62 5.26

CONDENSER

FAN

PROPELLER DIA. (in.) 22 22 22 22 22 22 22

FAN MOTOR HP

14141414141414

NOM. CFM TOTAL 1,800 2,200 2,400 2,400 2,400 2,800 2,800

CONDENSER

COIL

ROWS DEEP 1111111

FINS PER INCH 18 16 20 18 16 13 20

FACE AREA (Sq. Ft.) 8.3 8.3 8.3 8.3 11.7 16.4 16.4

CHARGE REFRIGERANT 22 (lbs./oz.) 3 / 4 3 / 5 3 / 13 3 / 10 4 / 7 5 / 15 5 / 15

FILTER FACE AREA (Sq. Ft. / Qty. / Size) 2.14 / 2 / 14" x 22"

COMPRESSOR HERMETIC Type, (Qty. = 1) Recip Recip Recip Recip Recip Scroll Scroll

TABLE 3 - PHYSICAL DATA

Get other manuals https://www.bkmanuals.com