GENERAL

This control panel provides the interface between the furnace

and the heat pump system.

The Heat Pump is the primary source of heat for the building

when the outdoor temperature is above the balance point. The

furnace provides supplemental heat when the outdoor tem-

perature is below the balance point. When the outdoor tem-

perature is below the setting of the low temperature cut-off,

only the furnace can operate.

Acomplete Maxi-Mizer Add-On System consists of the follow-

ing components (all shipped separately).

1. Outdoor Unit - E*FH with YorkGuard control

2. Indoor Coil - G1FD, G3US, G3HC, G1UA, G3UA or G2UT

3. Control Panel - 2AC02700801

4. Heat Pump Thermostat (2TH11702224, 2TH11702424, or

2ET11700224)

5. Furnace (gas, oil or electric)

SeetheE*FHtechnicalguidefortheapprovedcombinationsof

indoor coils and units.

The indoor coil must be installed down-stream of the furnace

discharge. The furnace/heat pump orientation may be upflow,

horizontal or downflow. Make sure that the indoor coil is being

applied within its application limitations.

LIMITATIONS

The installation of this unit shall be in accordance with all the

regulations of the authorities having jurisdiction. All lo-

cal/nationalcodesandstandardsonelectricalsystem,fuel-burning

appliances, and mechanical refrigerant systems must be ob-

served.

Observealloftheapplicationlimitationsandclearancerequire-

ments for the outdoor unit, the furnace and the indoor coil.

ELECTRICAL DATA FOR CONTROL PANEL

The voltage limitations of the furnace must be determined by

the installer.

Determine the CFM capability of the furnace and the CFM re-

quirement of the heat pump system, and make sure the CFM's

are compatible. If the furnace can't deliver enough air or deliv-

ers too much air, the system will not operate properly. Do not

add a heat pump to any furnace where the existing furnace

blower can not provide sufficient air flow.

WARNING:Some indoor coils may be shipped with a substan-

tialrefrigerantcharge.Neverallowafurnacetoop-

erateon the heatingcyclewithoneofthesecoils in

place but not connected to the rest of the heat

pump system.

INDOOR COIL - LOCATION AND MOUNTING

Theindoorcoilmustbeinstalledin the discharge air side of the

furnace. The coil should be centered on the furnace discharge

in a factory supplied casing. No modification of any part of the

furnace is permitted.

The casing provides an insulated enclosure which properly lo-

catestheindoorcoil attheminimum requireddistancefromthe

furnace.At least1"spacemustbemaintainedbetweenthefur-

nace discharge and the underside of the coil drain pan.

See coil installation instruction for more information concern-

ing coil mounting.

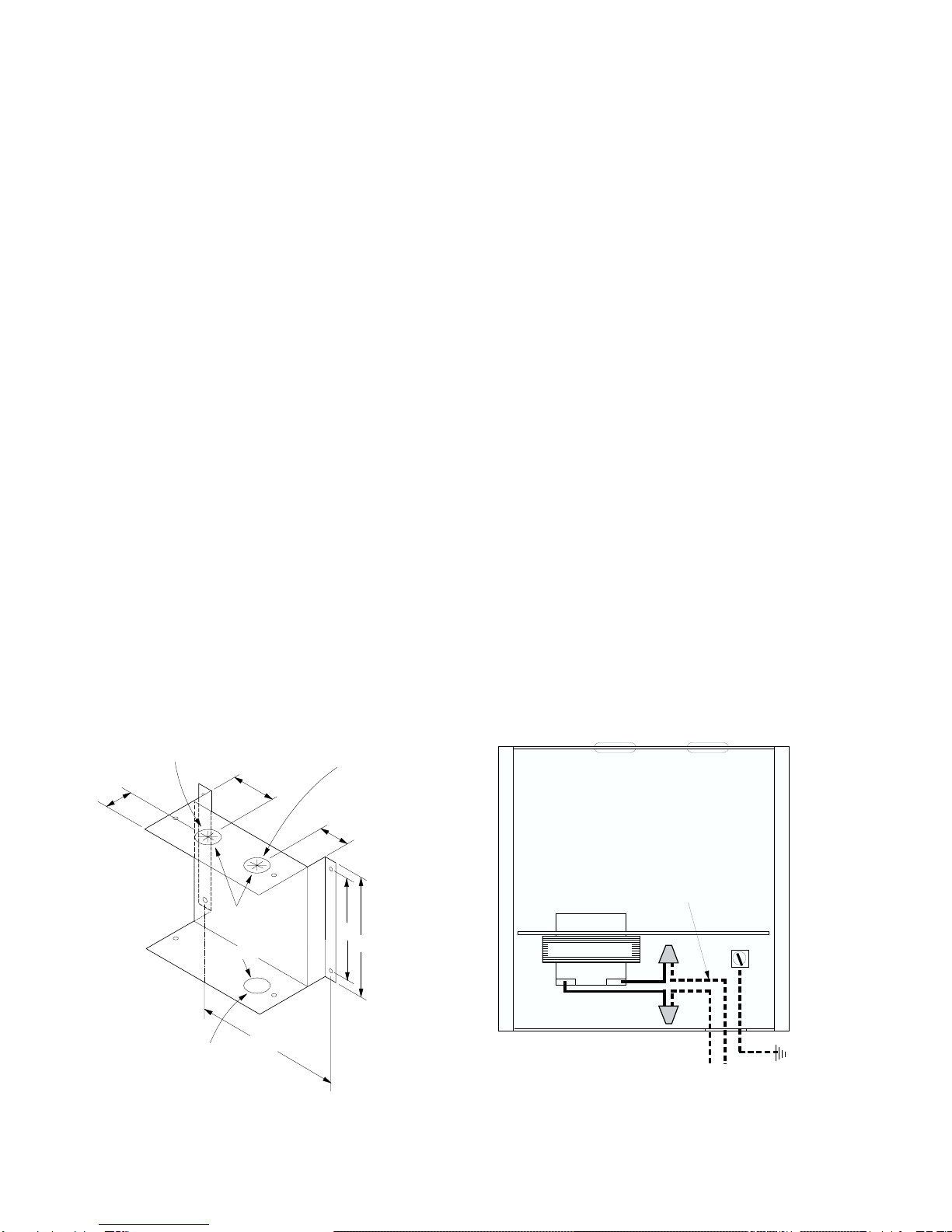

CONTROL PANEL MOUNTING

The control panel should be mounted on a nearby wall within the

reachof its 10 footlong sensor wire.This wire shouldbe carefully

routed from the control panel into the indoor coil casing.

CAUTION: Avoidroutingthesensorwireoveranysharpsheet

metal edges or any high temperature surfaces.

Mounting holes and screws are provided to secure the control

panel to the mounting surface. See Figure 1 for control panel

dimensions and hole locations.

NOTE: The control panel should never be mounted in or on

the furnace enclosure or discharge plenum. During

heating operation, high temperatures could damage

some of its components.

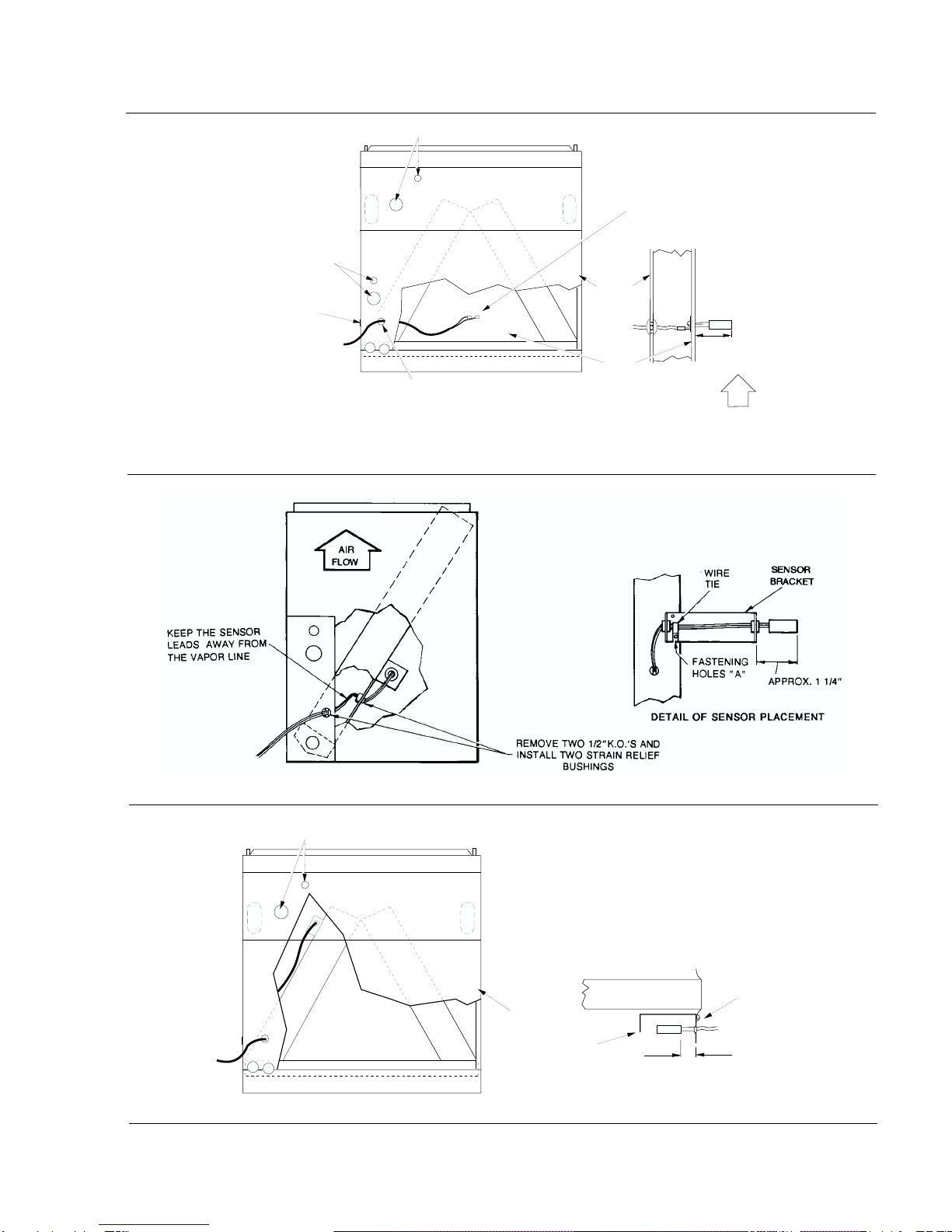

BRACKET AND SENSOR INSTALLATION

The mounting bracket and sensor location varies with the type

of coil and the application of that coil. Notice mounting bracket

fastening holes shown in illustration below:

®

MODEL 2AC02700801

Power Supply*

Voltage Min. - Max.

Min. Ckt. Amp.

Max. Fuse Size, Amps

Min. Wire Size (60°C), AWG

115-1-60

103 - 127

0.5

15

14

*PowersupplyfortheAdd-oncontrolpanelonly.Seetheinstallationinstructionsandtheunit

instructions and the unit data plate for the power supply of the outdoor unit.

CAUTION

THE ENCLOSED INSTALLATION INSTRUCTIONS AND ANY APPLICABLE

LOCAL, STATE, AND NATIONAL CODES INCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

THIS PRO DU CT M US T BE IN STALLED IN STRICT CO M PLIANCE W ITH

WARNING

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

INCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

MODELS 2AC02700801 035-14216

ADD-ON CONTROL PANEL

FOR USE WITH

E*FH HEAT PUMPS

INSTALLATION INSTRUCTION Supersedes: Nothing 545.01-N10Y (1296)