2

■

EPDT-253b

■

5. Nominal Size Selection

To make the best use of the product and to satisfy the operating requirements to the maximum, take

notice of the following.

4.1 Selection of nominal size

Select a nominal size of the product equivalent to that of the pipe (nominal pipe size = nominal size

of strainer). Note that use of a smaller nominal size increases the pressure loss through the strainer,

and may possibly reduce the equipment inlet pressure below the specified limit.

4.2 Selection of nominal pipe size

When selecting an appropriate nominal pipe size, it is necessary to consider fluid type, maximum flow rate,

permissible pressure loss, costs of piping and equipment, etc. If the nominal pipe size is smaller, the costs

of piping and equipment decreases while the pressure loss through the pipe increases to generate

disturbances, possibly resulting in pipe wear, noise and/or vibration. If the nominal pipe size is too large,

not only the costs of piping and equipment but also the thermal loss increase. As a reference, the

standard flow velocity is specified in the Japanese Industrial Standards (JIS) as a guide to select an

appropriate nominal pipe size. See the following table.

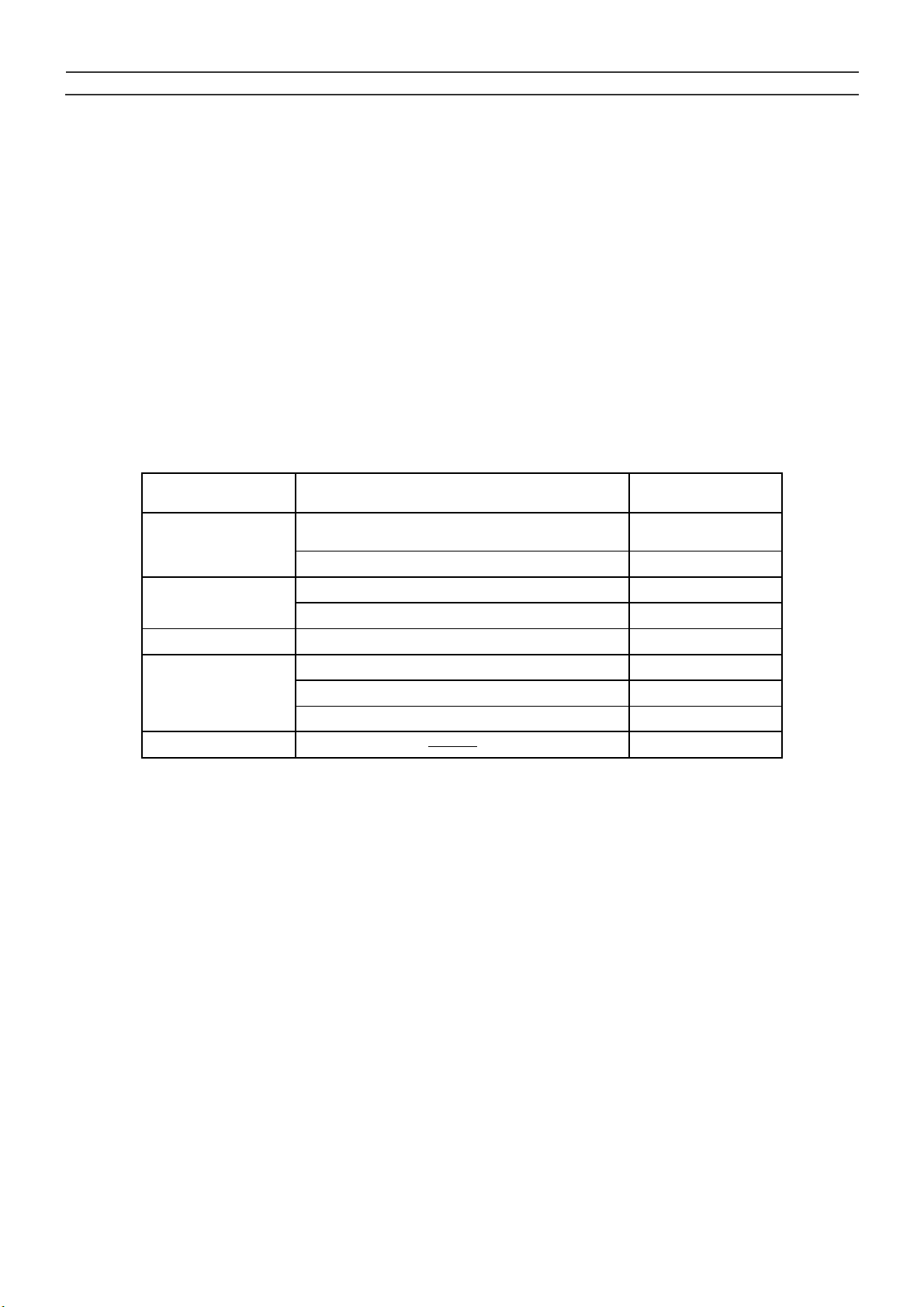

<<Standard flow velocity>>

Fluid Remarks Standard flow

Saturated steam

Auxiliary piping for vacuum or

small-

15 m/s [10-20]

Large-diameter piping 30 m/s [20-40]

Superheated steam Piping diameter: approx. φ75 – φ250 40 m/s [30-50]

Piping of high-grade material 70 m/s [65-80]

Inlet of steam coil 0.3-0.7 MPa 30 m/s [25-30]

Air

Higher pressure: 1.0 MPa or more 20 m/s [20-25]

Lower pressure 15 m/s [5-15]

Extremely low pressure: 0.1 MPa or less 10 m/s [3-10]

Water, Oil 2 m/s [2- 4]

* This table is based on the requirements provided in JIS F 7101 [Shipbuilding – Pipes

of machinery – Standard velocity of flow].