2

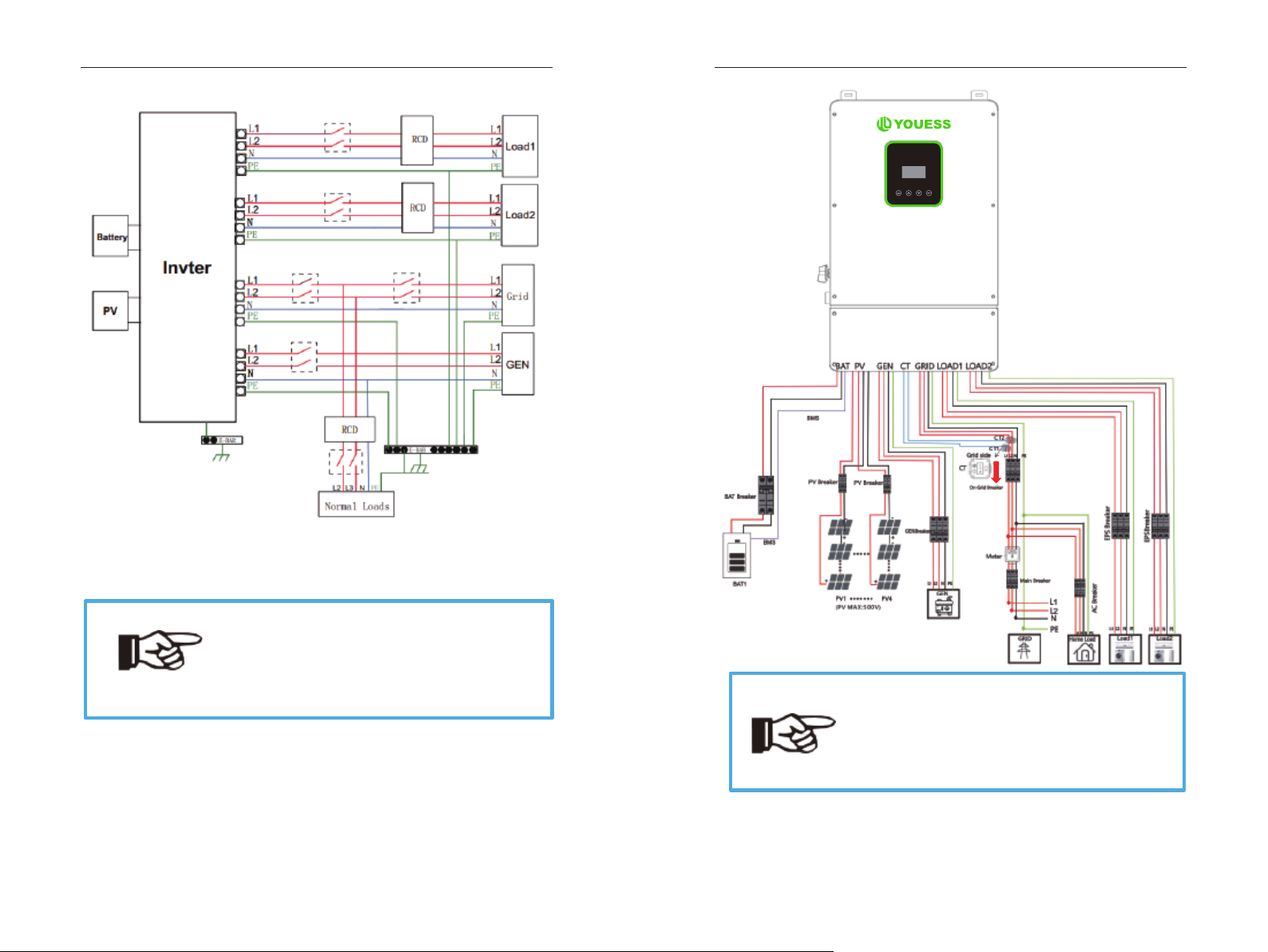

9.2 GENERATOR OPERATION NOTES ............................................................................................................61

9.3 GENERATOR SETTING .................................................................................................................................61

10. INVERTER PARALLEL GUIDE........................................................................................................................... 63

10.1 PARALLEL SYSTEM DIAGRAM ................................................................................................................. 63

10.2 PARALLEL COMMUNICATION CABLE CONNECTION...................................................................... 67

10.3 PARALLEL OPERATION NOTES............................................................................................................... 67

10.4 PARALLEL SYSTEM SETTING ................................................................................................................... 68

11. ADVANCED MODE OPERATION GUIDE ..................................................................................................... 69

11.1 ADVANCED MODE INTRODUCTION..................................................................................................... 69

11.2 ADVANCED MODE SETTING................................................................................................................... 70

12. FAULT DIAGNOSIS AND SOLUTIONS.......................................................................................................... 72

1

CONTENTS

1. NOTES ON THIS MANUAL................................................................................................................................. 3

1.1 SCOPE OF VALIDITY....................................................................................................................................... 3

1.2 TARGET GROUP.............................................................................................................................................. 3

1.3 SYMBOLS USED.............................................................................................................................................. 3

2. SAFETY.................................................................................................................................................................... 4

2.1 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 4

2.2 EXPLANATION OF SYMBOL ....................................................................................................................... 8

3. INTRODUCTION ................................................................................................................................................... 9

3.1 BASIC FEATURES ............................................................................................................................................ 9

3.2 SYSTEM DIAGRAM........................................................................................................................................ 9

3.3 WORK MODES ..............................................................................................................................................12

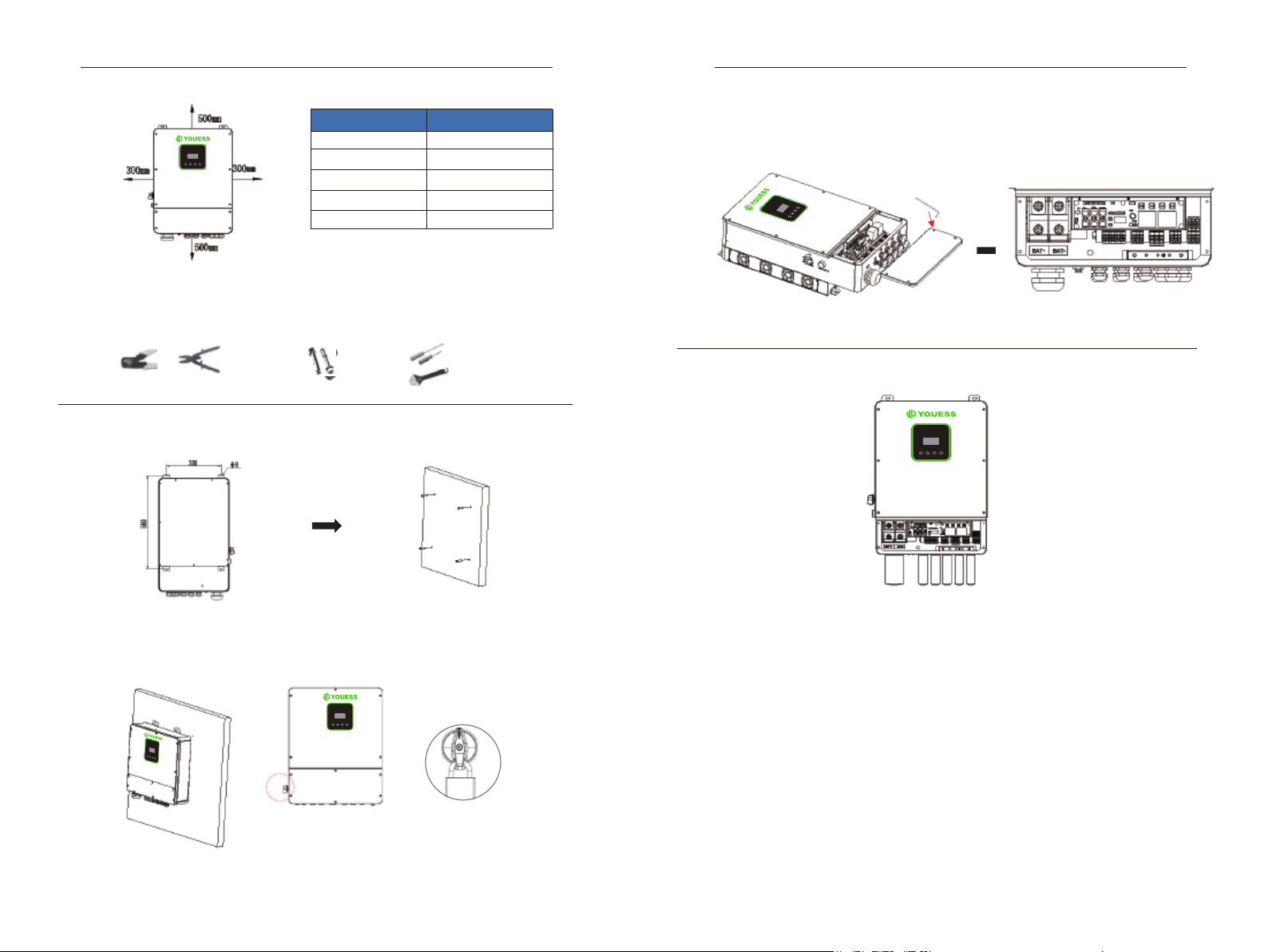

3.4 DIMENSION ................................................................................................................................................... 13

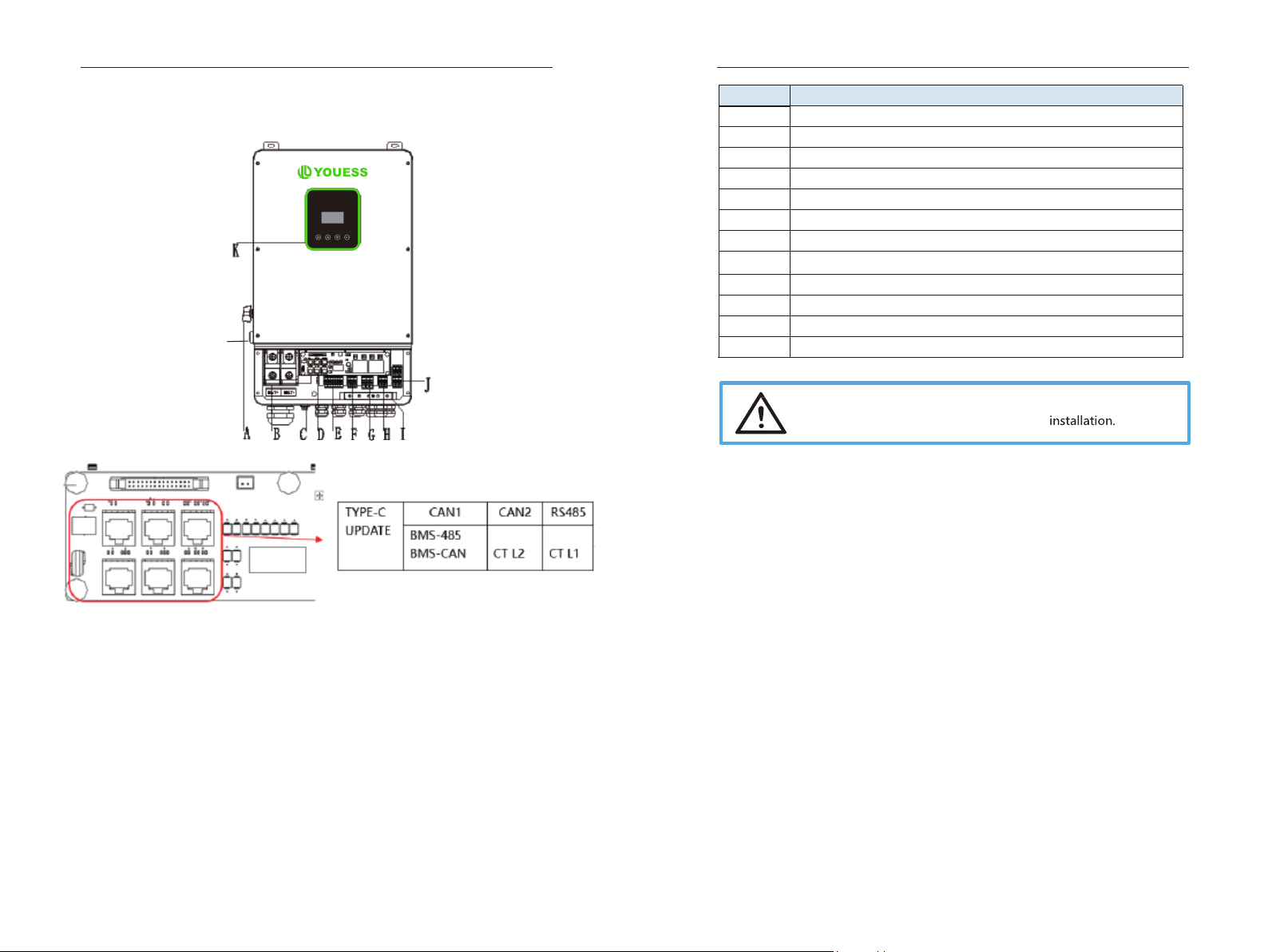

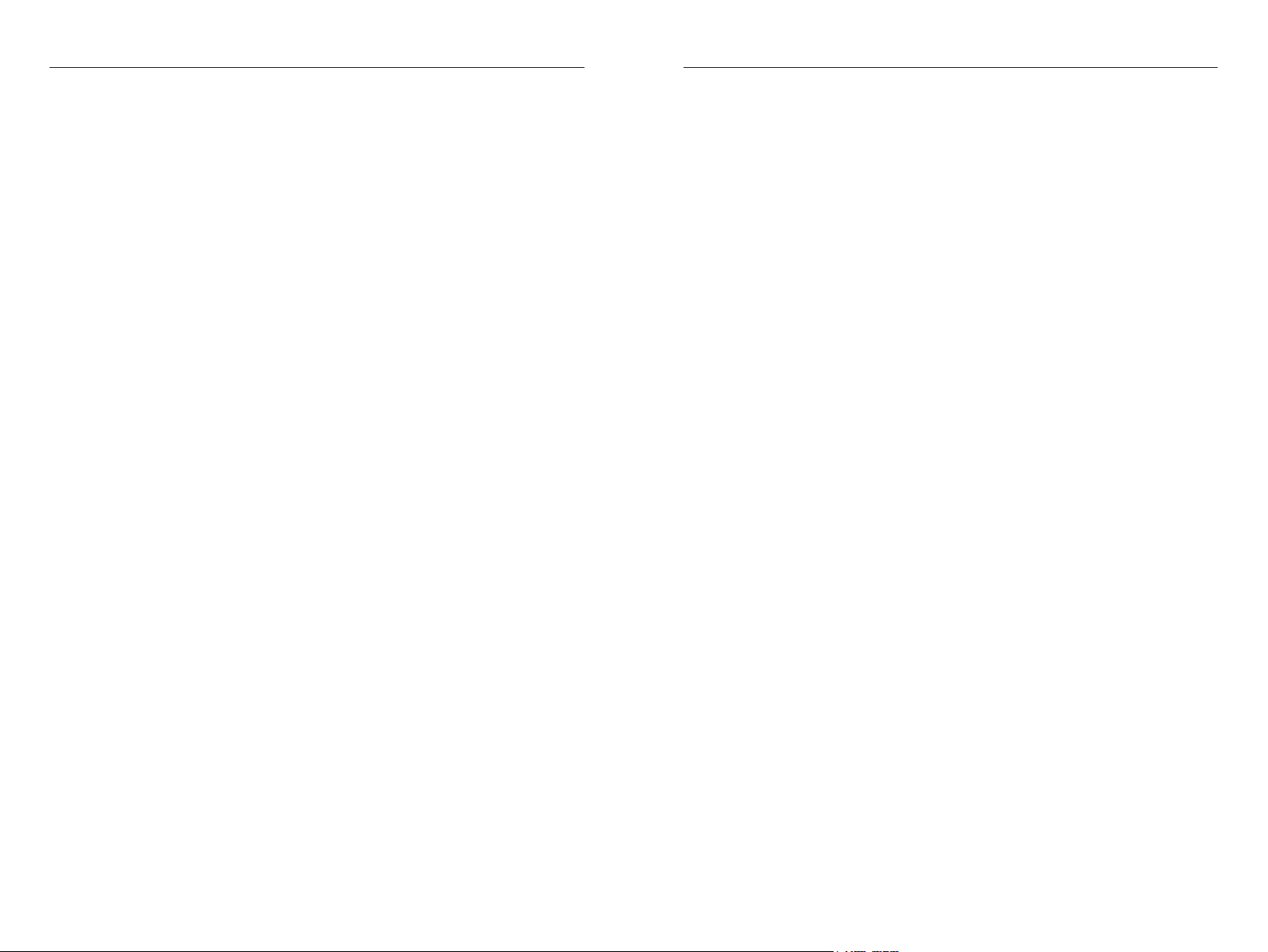

3.5 TERMINALS OF PV INVERTER ...................................................................................................................14

4. TECHNICAL PARAMETERS................................................................................................................................16

4.1 INVERTER SPECICATION .............................................................................................................................16

5. INSTALLATION ..................................................................................................................................................... 18

5.1 CHECK FOR PHYSICAL DAMAGE ..............................................................................................................18

5.2 PACKING LIST ................................................................................................................................................18

5.3 MOUNTING ...................................................................................................................................................18

6. ELECTRICAL CONNECTION ............................................................................................................................ 22

6.1 PV CONNECTION ........................................................................................................................................ 22

6.2 GRID CONNECTION (GEN CONNECTION) .......................................................................................... 23

6.3 BACK-UP:LOAD1 AND LOAD2 CONNECTION ...................................................................................... 24

6.4 BATTERY CONNECTION............................................................................................................................ 26

6.5 WIFI CONNECTION (OPTIONAL)............................................................................................................ 28

6.6 GPRS CONNECTION (OPTIONAL).......................................................................................................... 28

6.7 CT INSTALLATION INSTRUCTIONS......................................................................................................... 29

6.8 E-STOP INSTALLATION .............................................................................................................................. 30

7. LCD OPERATION .................................................................................................................................................31

7.1 CONTROL PANEL .......................................................................................................................................... 31

7.2 INSTRUCTIONS FOR LED INDICATOR.....................................................................................................31

7.3 INSTRUCTIONS FOR THE USE OF THREE MODES ............................................................................. 32

8. LCD OPERATION ................................................................................................................................................ 35

8.1 LCD INTERFACE ............................................................................................................................................ 35

9. GENERATOR USE OPERATION GUIDE........................................................................................................... 59

9.1 GENERATOR USE DIAGRAM...................................................................................................................... 59