1. Apply a thin coat of lubricant to the o-rings

on the plug port. Wipe off any excess

lubricant with a lint-free cloth.

2. Insert the port plug into the empty port and

press until firmly seated.

3. Finger-tighten the port plug clockwise to

install. If necessary, use the sensor

installation tool to make sure that the plug is

fully seated into the port.

NOTE: he o-rings will not be visible if a

port plug is correctly installed. Do not over-

tighten the port plug; over-tightening can

cause damage to the port plug or bulkhead

not covered by the warranty.

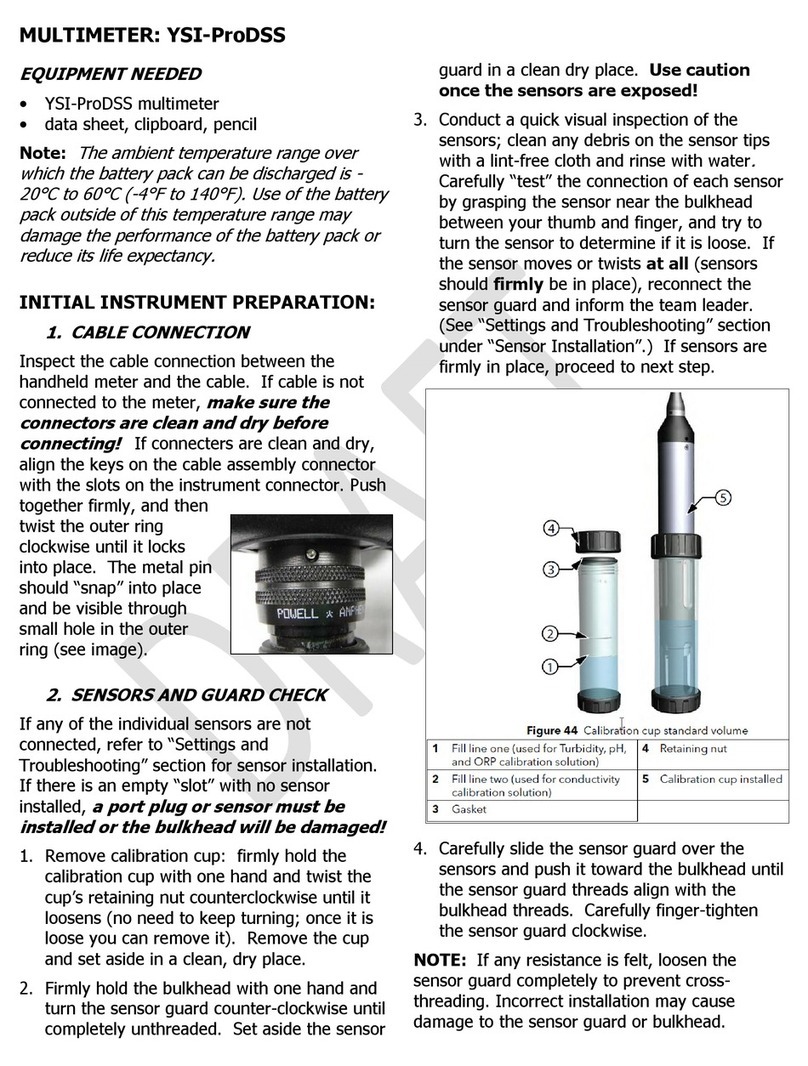

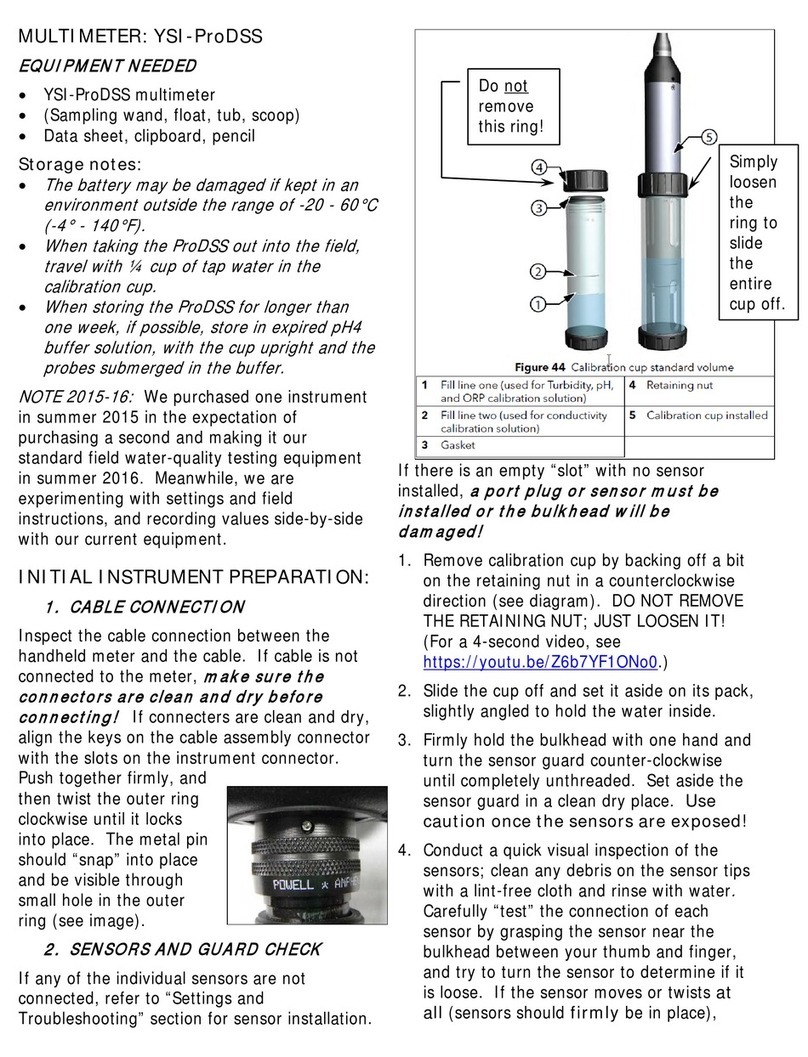

Sensor Guard Installation

Without the sensor guard, the sensors are

extremely vulnerable to environmental damage.

1. Carefully slide the sensor guard over the

sensors and bulkhead. Push the sensor

guard toward the bulkhead until the sensor

guard threads align with the bulkhead

threads.

2. Carefully finger-tighten the sensor guard

clockwise.

NOTE:

If any resistance is felt, loosen the

sensor guard completely to prevent cross-

threading. Incorrect installation may cause

damage to the sensor guard or bulkhead that is

not covered by the warranty.

USB port cleaning

If the USB port cover gets

dislodged, dirt can get into

the port area. However, the

port entry is waterproof

even when the port is exposed. o clean dirt

from the port area:

•Flush the port area out with water.

•Pour isopropyl alcohol into the port area

and let it sit for 30 seconds.

•Pour out the alcohol and let dry before

replacing the port cover.

Battery pack troubleshooting

If the instrument is not turning on, do the

following:

1. Attempt to charge the unit: Using YSI

charging equipment only, plug unit into

the AC adapter with the USB connector

(see figure on next page).

2. If this does not power on the unit,

remove battery pack cover and examine

battery pack (see figure on previous

page).

NOTE: Do not re ove the battery pack

if it is hot to the touch, is producing an

odd odor, or is leaking a fluid.

Removing and examining the battery pack

needs to be done with extre e care by a

team leader and in a dry, clean place,

preferably not in the field!

a) Remove the battery pack cover by

unscrewing (counter-clockwise) the

four screws with a flat or Phillips

head screwdriver (the retaining

screws are captured into the cover

and are not removable).

b) Inspect the battery pack; make sure

the battery pack connector is

properly connected to the

instrument.

c) If the connectors do not appear to

be properly connected, grasp the

battery pack connector with two

fingers and pull the connector

straight up to disconnect and

remove. Inspect the connector and

instrument pin connectors for any

debris or damage. If the connectors

look OK, align the battery pack

connector wire terminals with the

three instrument pins and connect

the battery pack.

d) If connectors look properly

connected, reinstall the battery

cover and attempt to charge the unit

again. If the unit still will not turn

on, the battery pack may need to be

replaced. (Before ordering a new

battery pack, call YSI at

800.765.4974 and troubleshoot

problems with a ProDSS tech.)