a) From the Run Screen, select the

System

button .

b) Scroll down and select Logging. In the

Logging menu, select Data ID and select

Replicate.

c) Exit back to the Run Screen and collect

and record a second reading (same as

above). NOTE: Don’t forget to switch

the

Data ID

back to Primary in preparation

for the next site.

4. Remove the probe from the stream. Fill the

calibration cup with ~2” of clean water

(stream water if clear, purified if not) and

tighten. If you plan to do a DO drift check,

loosely screw the cup onto the bulkhead to

allow for atmospheric venting and keep the

probe in an upright position in the shade.

5.

Record t e meter number

, if the data

sheet directs you to do so. If you are not

submitting the data to Clallam County, record

the latest calibration dates for DO (“Winkler”),

pH, conductivity, turbidity, and temperature.

Select the

File button

, select View GLP,

and scroll through to see when the

instrument was last calibrated.

6.

Record t e data:

Select the

File

button

and then select View Data and Show

Data. (If no data is displayed, make sure you

have the right date and time entered at the

bottom.) Scroll down until you find the

proper site and data ID (Primary Sample or

Replicate). Then record the readings on your

data sheet, in the following order, using our

rounding convention as necessary (see

Quality Assurance protocol):

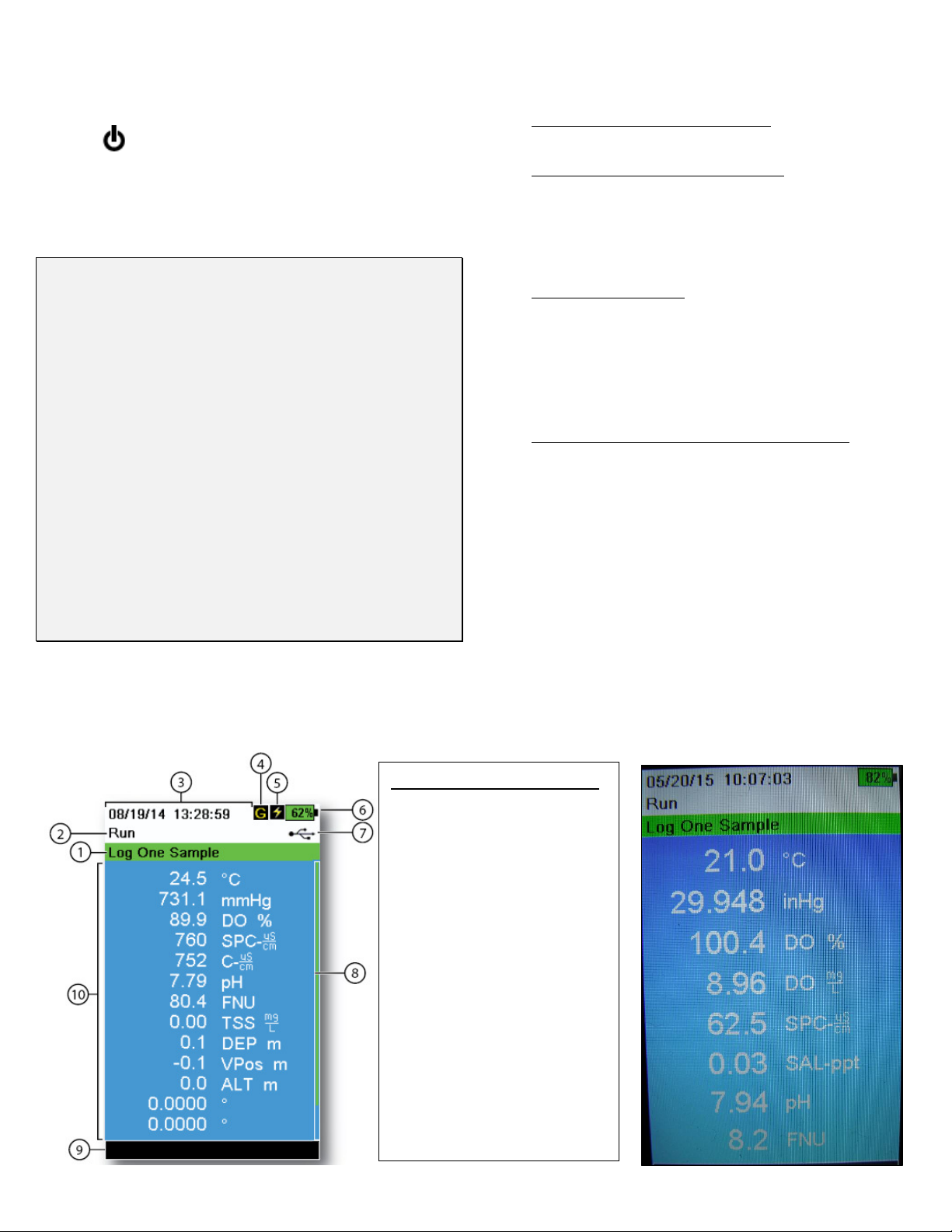

a)

Temperature:

to nearest .1°C

b)

Pressure:

to nearest . 1 inHg

c)

DO % Saturation:

to nearest .1%

d)

DO Concentration:

to nearest .1 mg/L

e)

Specific Conductivity:

to nearest whole

µS (microSiemens)

f)

Salinity:

to nearest .1 ppt (parts per

thousand)

g)

pH:

to nearest .1

h)

Turbidity:

to nearest whole FNU

7. If you performed replicates, record those

readings as well, and check the “Water

Chemistry—General” protocol to see if your

pairs of readings are within the acceptable

precision limits; resample as needed.

8. Record time and full initials of a single

sampler taking responsibility for the data; this

should be someone who has been properly

trained (see “Quality Assurance” protocol).

9.

DO drift c eck—optional, but desirable to

perform while “getting to know” the instru-

ment, until we’re completely confident in it:

a) Hit Esc to return to the “Run” Screen to

view the DO% saturation. If you haven’t

already, fill the calibration cup with ~2” of

clean water (stream or purified), and allow

the probe to stabilize:

STABILIZATION CRITERION:

During

a period of 2 minutes, bot DO Sat %

and temp (°C) stay wit in 0.1 of t eir

initial readings.

b) Do NOT hit any buttons on the meter.

When stabilization is reached, you’ll want

the DO % Saturation reading to be

between 98-1 2%; if not, you’ll need to

re-calibrate the meter and re-take the

readings, or your data may be flagged as

“estimated” or “rejected”.

c) If the stabilized DO % Saturation reading

is satisfactory, record it to the nearest

.1%.

d) Record the time and sampler’s initials.

1 .Turn off t e meter, fully tig ten t e

calibration cup and place the unit in the

field bag.

COMMON SENSE AND EXPECTED RANGES:

Please compare your readings with the

expected ranges on the datasheet. If you’re outside

the expected range, consider re-sampling or

troubleshooting with your fellow samplers.

Conductivity readings in particular have a

nasty habit of being wacky. Stream conductivity is

rarely lower than 25 µS. If your readings are lower

than this, you might not have held the probe

completely underwater. Try taking another set of

readings.