YSI ProDSS supplement 2 July 2015

your thumb and pointer finger, and try to

turn the sensor to determine if it is loose If

the sensor moves or twists at all (sensors

should firmly be in place), reconnect the

sensor guard and inform the team leader If

any sensor is loose refer to the “Settings

and Troubleshooting” section under “Sensor

Installation” If sensors are firmly in place,

proceed to next step

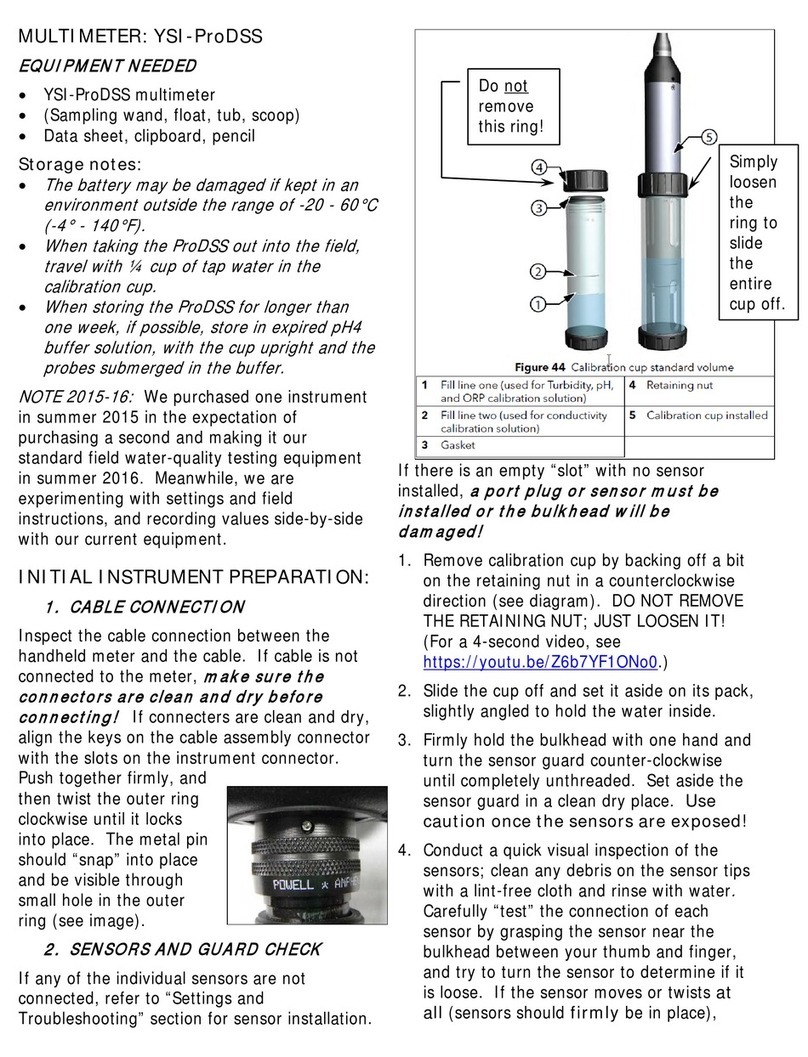

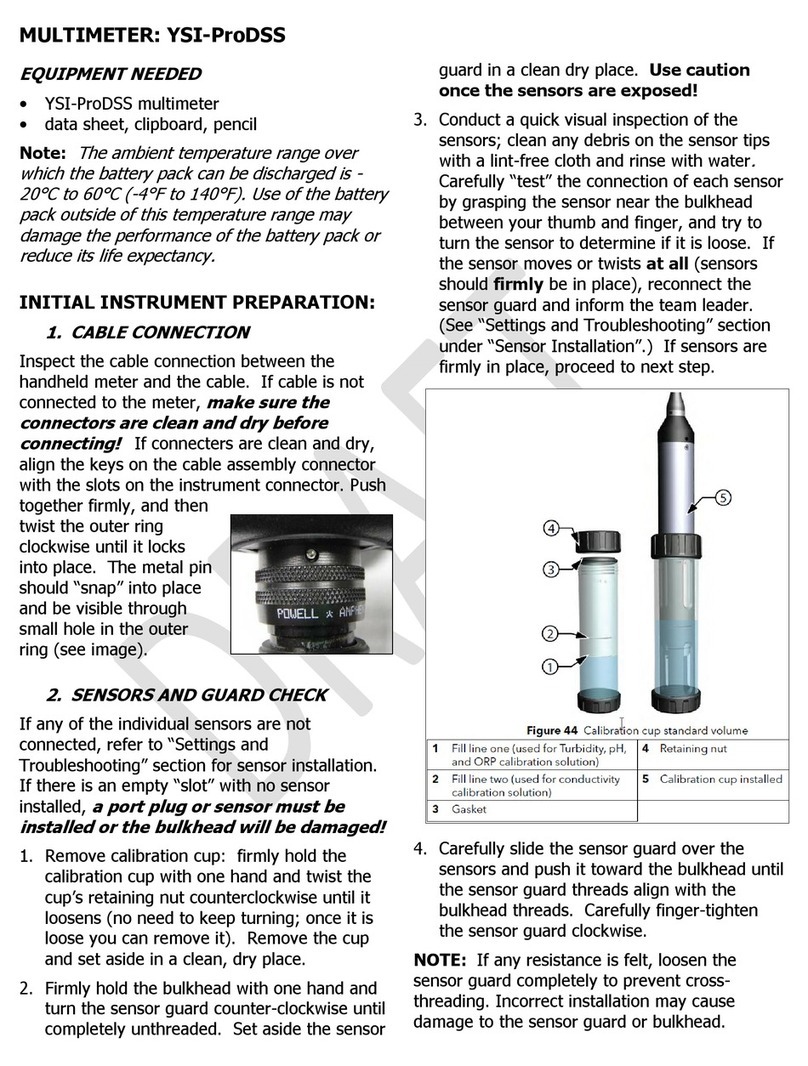

4 Carefully slide the sensor guard over the

bulkhead and attached sensors/port plugs

Push the sensor guard toward the bulkhead

until the sensor guard threads align with the

bulkhead threads Carefully finger-tighten

the sensor guard clockwise

NOTICE:

If any resistance is felt, loosen the

sensor guard completely to prevent cross-

threading Incorrect installation may cause

damage to the sensor guard or bulkhead that is

not covered by the warranty

INITIAL INSTRUMENT PREPARATION:

Where to sample: Pick an area where the

stream is flowing and appears to be well mixed

Do not sample downstream of where your

team has disturbed the bottom.

1 Turn on the meter by pushing the

power

key

to turn on the handheld To turn off

the meter, hold down the power key for 1 5

seconds If the handheld does not turn on,

inform the team leader The handheld could

have a dead battery, or the battery pack

may need to be inspected Removing and

examining the battery pack needs to be

done with extreme care by a team leader in

a dry, clean place, preferably not in the

field! For instruction on battery pack

removal, refer to the “Settings and Trouble

Shooting” section under “Battery

Troubleshooting” Once you have reviewed

the battery troubleshooting procedures, and

are in a dry, clean environment, make sure

that the battery pack is correctly installed

and charged

Charging the Internal Li-Ion Battery Pa k

Use YSI designated charging equipment only!

If the battery is not charged, the meter must be

charged from the AC power adapter

(strongest

charge source)

, directly from a computer USB

connection or from an external, portable USB

battery pack For the instrument to recognize

that it is using AC power, you must start

charging the ProDSS while on After the

instrument recognizes it is being charged, it can

be turned off to finish charging When using

the AC adapter, it takes approximately 14 hours

to charge the ProDSS battery when the

instrument is turned off during the charge The

amount of time required to completely charge

the battery pack when the ProDSS is initially

turned on during the charge is approximately 9

hours Expected battery life:

• ProDSS instrument only - 48 hours

• ProDSS with fully loaded cable assembly and

25% (Default) LCD brightness - 20 hours

• ProDSS with fully loaded cable assembly and

100% LCD brightness - 14 hours

For maximum battery life, keep the battery

40% to 80% charged Also, a larger

discharge (e g to 50%) is better than a small

discharge (e g to 90%) between recharges

2 The main display, or “run Screen” will

appear, take note of the battery life at the

top right, which is displayed as a

percentage If the battery life is low, inform

your team leader

3 Study the main “run” screen Confirm the

following:

•The date and time are correct:

The date and time should be displayed at

the top of the screen; if not, refer to the

“Settings and Troubleshooting” section

under “Date/Time”

•Logging is correct:

At the top of the screen in the green bar

it should read “log one sample”; if not,

refer to the “Settings and

Troubleshooting” section under “Logging

Data”