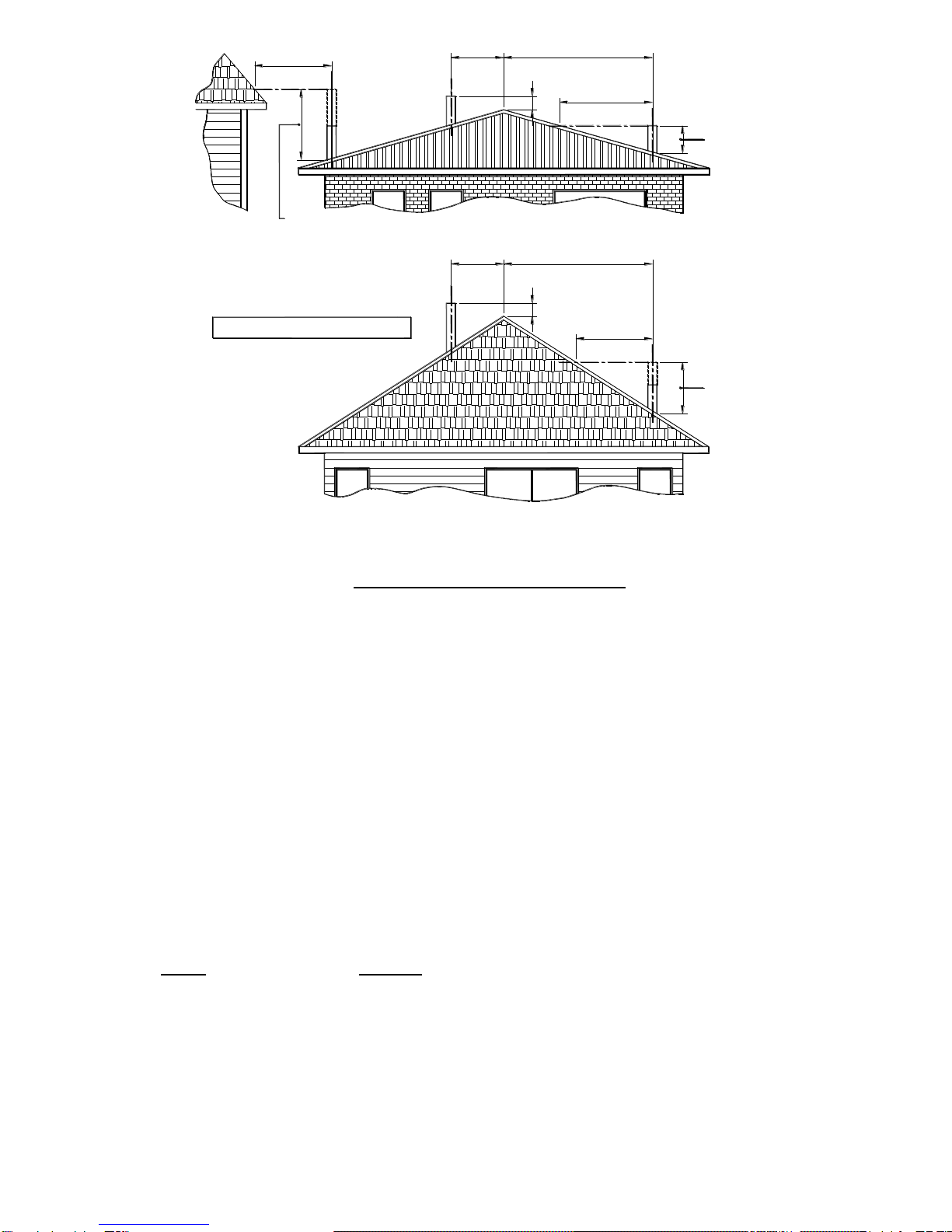

IMPORTANT INFORMATION

A. THE APPLIANCE AND FLUE SYSTEM SHALL BE INSTALLED IN COMPLIANCE WITH AS/NZS

2918:2001 AND THE APPROPRIATE REQUIREMENTS OF THE RELEVANT BUILDING CODE OR

CODES.

B. APPLIANCES INSTALLED IN ACCORDANCE WITH THIS STANDARD SHALL COMPLY WITH THE

REQUIREMENTS OF AS/NZS 4013 WHERE REQUIRED BY THE REGULATORY AUTHORITY I.E. THE

APPLIANCE SHALL BE IDENTIFIABLE BY A COMPLIANCE PLATE WITH THE MARKING “TESTED

TO AS/NZS 4013”

C. ANY MODIFICATION OF THE APPLIANCE THAT HAS NOT BEEN APPROVED IN WRITING BY THE

TESTING AUTHORITY IS CONSIDERED TO BE IN BREACH OF THE APPROVAL GRANTED FOR

COMPLIANCE WITH AS/NZS 4013

D. MIXING OF APPLIANCE OR FLUE SYSTEM COMPONENTS FROM DIFFERENT SOURCES OR

MODIFYING THE DIMENSIONAL SPECIFICATION OF COMPONENTS MAY RESULT IN HAZARDOUS

CONDITIONS. WHERE SUCH ACTION IS CONSIDERED, THE MANUFACTURER SHOULD BE

CONSULTED IN THE FIRST INSTANCE.

E. CRACKED AND BROKEN COMPONENTS E.G. GLASS PANELS OR FIRE BRICKS, MAY RENDER THE

INSTALLATION UNSAFE.

IF A WATERBOOSTER IS FITTED:

NOTE: A WATER BOOSTER CANNOT BE FITTED IN SOME CLEAN AIR ZONES

(CHECK LOCAL COUNCIL REGULATIONS)

A. DO NOT CONNECT TO AN UNVENTED HOT WATER SYSTEM

B. INSTALL IN ACCORDANCE WITH AS 3500.4.1 OR NZS 4603 AND THE APPROPRIATE

REQUIREMENTS OF THE RELEVANT BUILDING CODES.

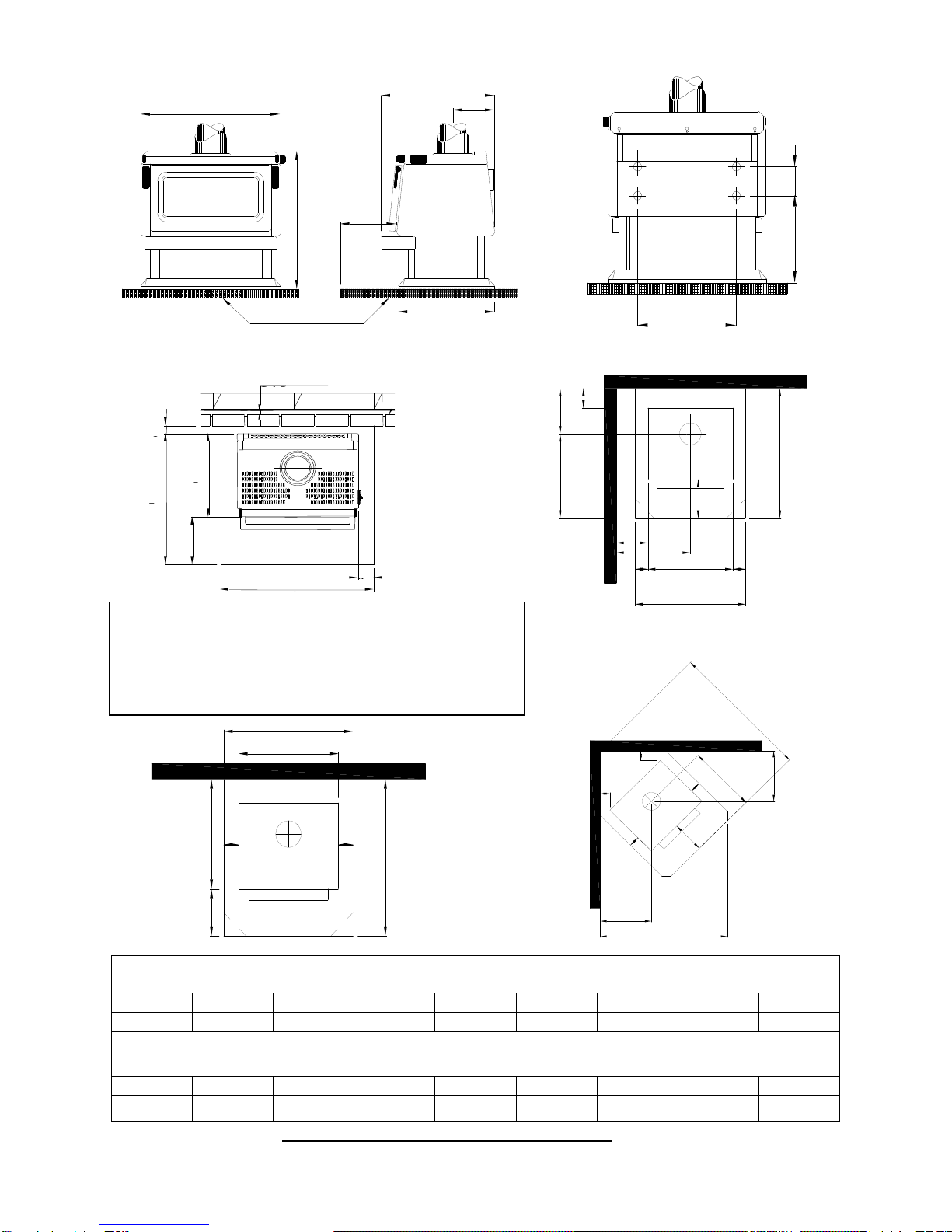

SEISMIC RESTRAINT

Secure the heater base to the hearth or sub-framing with Dynabolts or similar.

Follow local Council’s Specifications.