GENINS05 Page 8 28/08/2014

Troubleshooting

1. The foresail will not unfurl

NB. DO NOT USE FORCE TO UNFURL SAIL, otherwise damage to forestay may result.

Causes:

a. The jib halyard has wrapped round the luff foil.

Action: ease the jib halyard and re-furl. Free the halyard. Fit a diverter to the halyard if one is not already

installed.

b. The furling line is fouled.

Action: Free the furling line. Possibly adjust position of lead blocks, especially the one nearest the drum.

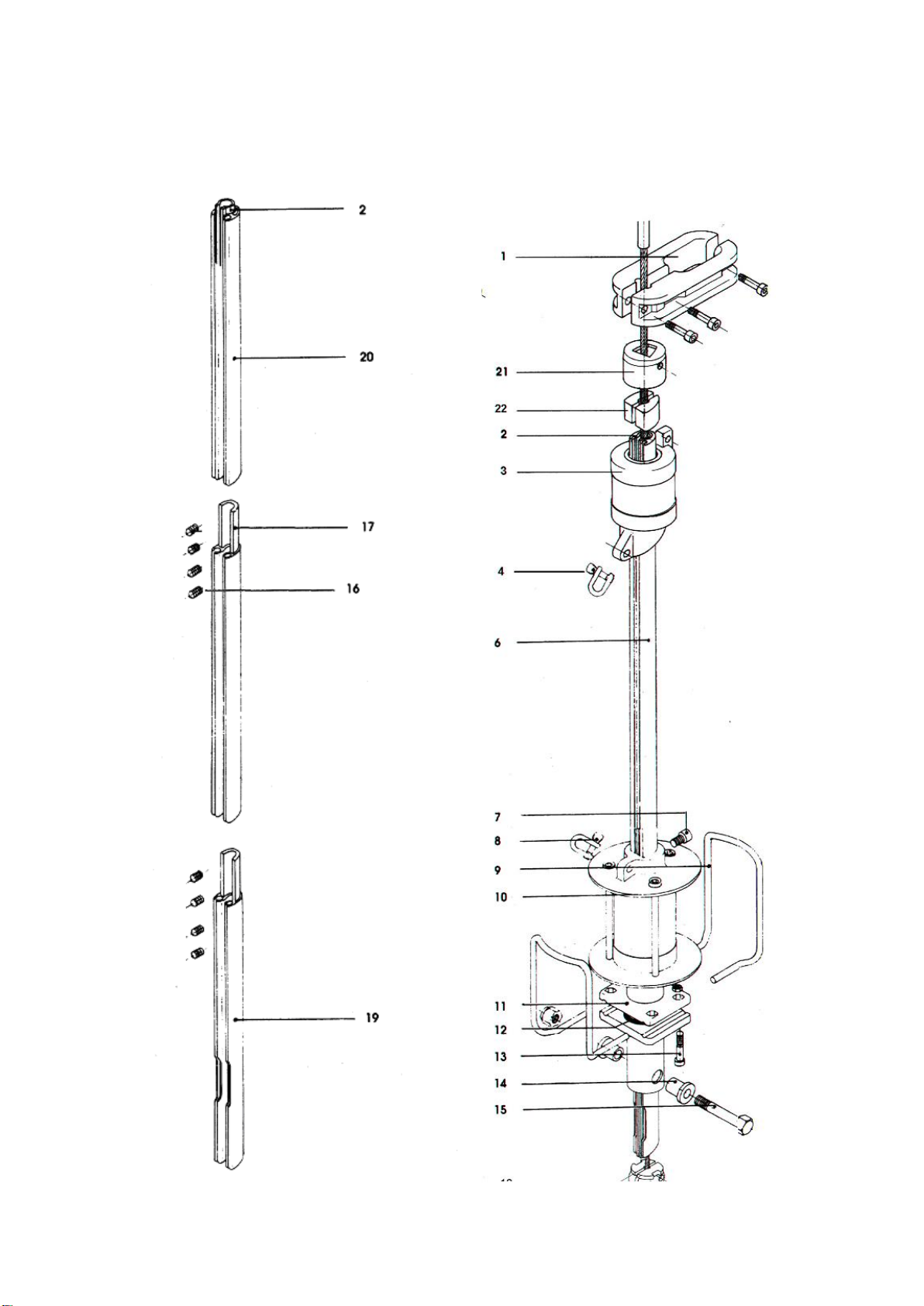

Ensure that the furling line passes through the stainless steel drum guard (9) without touching it (possible

chafe point).

c. The forestay is too slack.

Action: Tension the forestay.

d. The halyard is too tight.

Action: Ease off the halyard a small amount.

2. The foresail will not furl

Causes:

a. The jib halyard has wrapped round the luff foil.

Action: ease the jib halyard and try to unfurl. Free the halyard. Fit a Diverter to the halyard.

b. No line remaining on the drum.

Action: Unfurl the sail and undo the sheets. Gather the sail round the luff foil, then wind more line on the

drum.

c. The forestay is too slack.

Action: Tension the forestay.

d. The jib sheet is not released.

Action: release the sheet.

e. The halyard is too tight.

Action: Ease off the halyard.

f. Furling line fouled on the drum.

Action: Unfurl & remove the sail. Rewind the furling line. Unfurl with slight tension on the line. Do not have

excessive number of turns on the drum.

g. Furling line leads have too much friction and/or are showing signs of chafe.

Action: Use low friction blocks for furling line instead of fairleads. Ensure that the furling line is not fouling

the drum guard (9).

3. The sail is difficult to hoist

Causes:

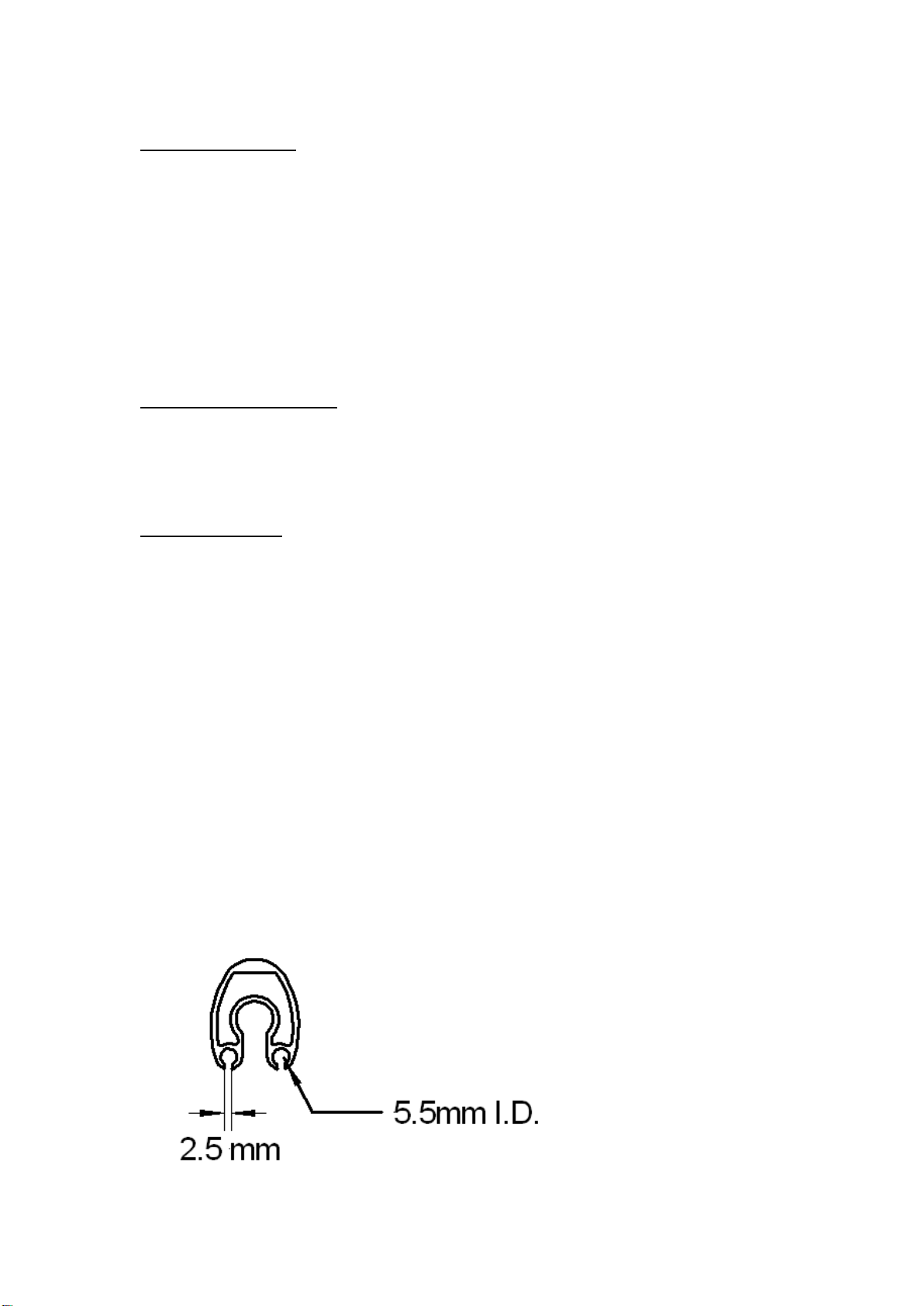

a. The sail luff rope is too thick - maximum 5mm finished size allowed (see page 5).

Action: refer to sailmaker.

b. Luff groove is obstructed

Action: clean groove.

c. The sail is wrongly positioned for entry.

Action: re-position the sail on the deck so that luff rope is more in line with direction of feed.

4. The luff cannot be tensioned sufficiently.

Causes:

a. The sail luff is too long for the foil.

Action: Shorten luff (refer to sailmaker).

b. The halyard is not sufficiently in line with the forestay.

Action: re-locate halyard diverter.

5. The sail cannot be lowered

Causes:

a. Halyard wrapped round top of foil.

Action: Slacken the halyard and try to untwist via the drum. Fit a diverter.

b. The halyard is stuck.

Action: check halyard routing (sheaves etc).

If you have any queries, contact Z Spars UK on +44 (0)1473 822130.