The ZAGI-400 X should be sprayed with #77 and covered with tape before any holes are

cut for radio installation. This will avoid getting spray adhesive in the radio compart-

ments or on the antenna. Most of the colors are transparent enough to see the servo

cutout marks through the tape. If a dark color tape is used, make some small impres-

sions with a pencil at the corners of the servo cutout marks.

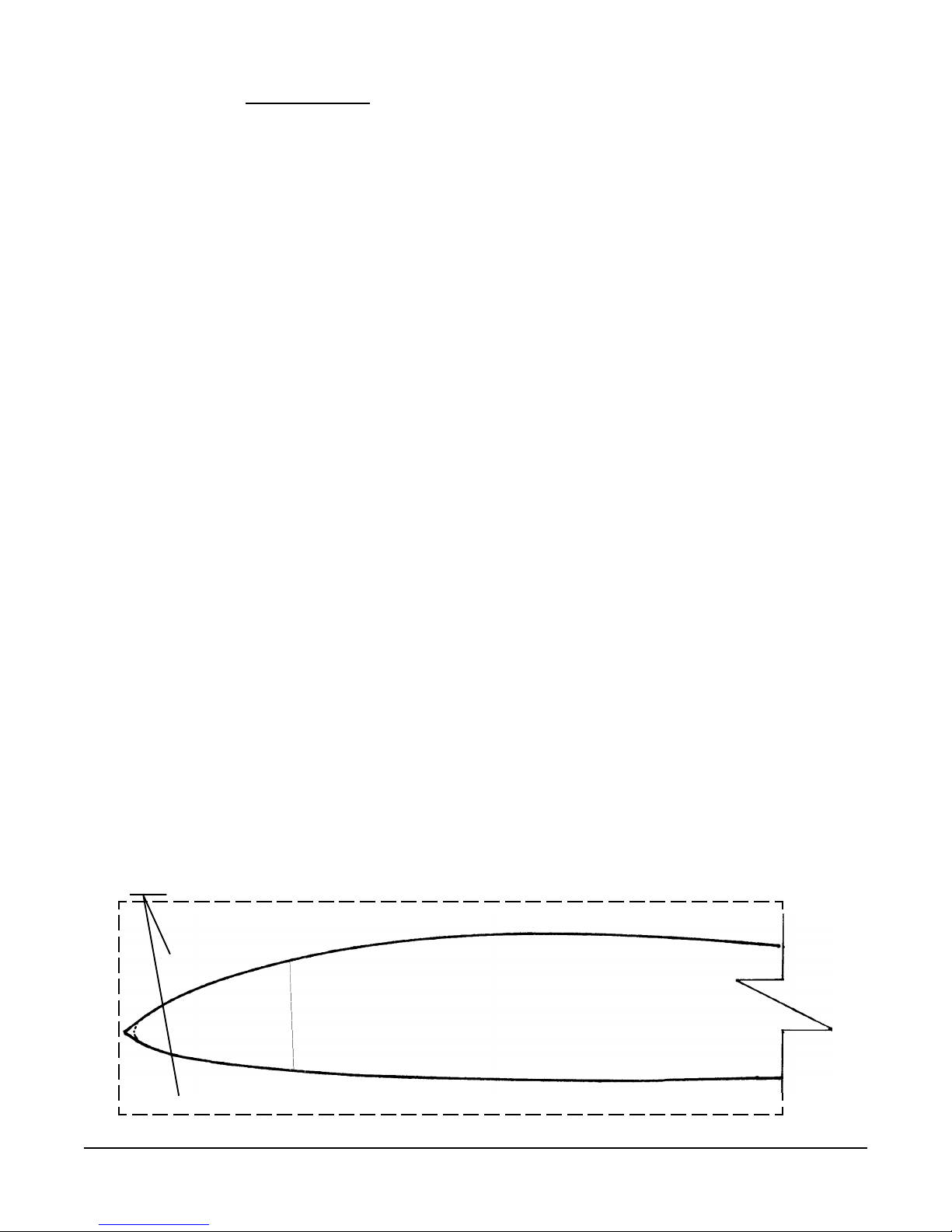

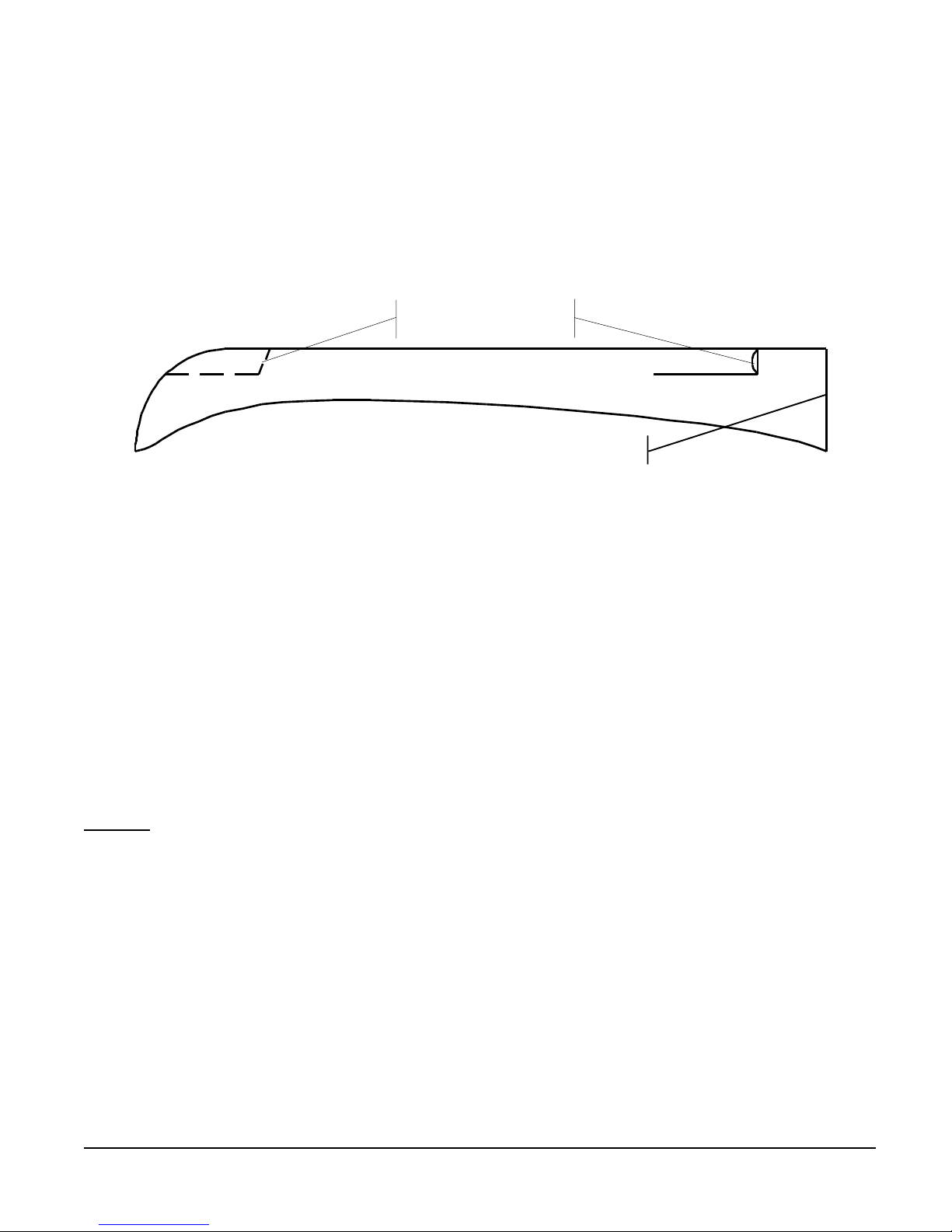

(See Figure 4) Vacuum the dust from the cores, beds and the work bench. Lay the wing

in the bottom beds top-side up. Apply a light coat of

#77

to cover the top of the entire

wing. Allow the adhesive spray to dry at least 30 minutes. Repeat this procedure on the

other side. Let the adhesive dry for 30 minutes. Lay the wing top-side up in the bottom

beds. Wrap a strip of 3/4” fiber filament tape around the trailing edge between the wing

tip and the prop cutout. Apply a strip of fiber tape to the trailing edge from the wing tip to

the opposite leading edge.

page 5

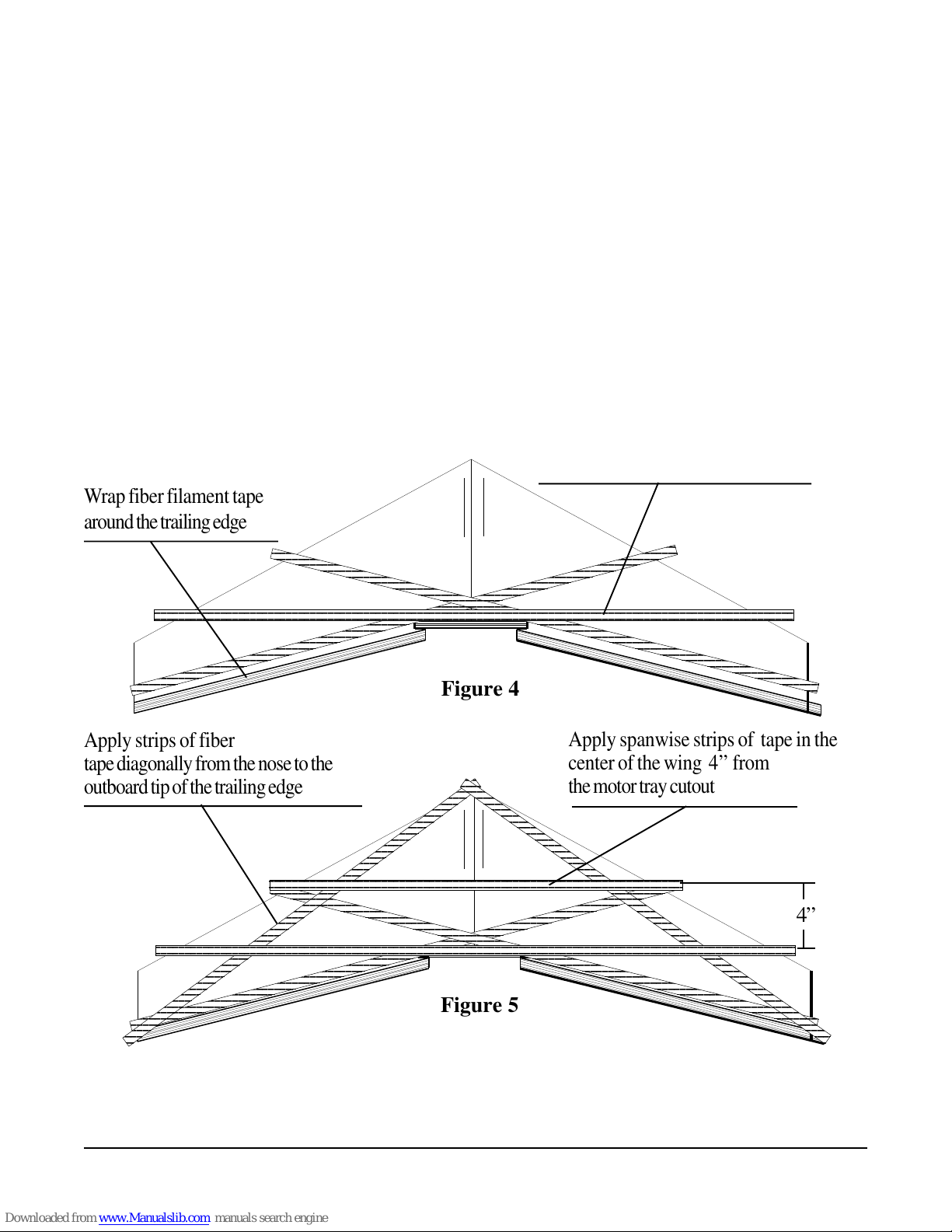

Apply spanwise strips of tape

at the motor tray cutout extending

to the leading edge on both sides

(See Figure 5)

Apply another strip of 3/4’’ fiber tape in the center of the wing 4’’ from the motor tray

cutout. Apply two strips of fiber tape diagonally from the nose to the outboard tip of the trailing edge.

Lay the wing bottom-side up in the top beds and repeat the same taping procedure on the bottom side.

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

Figure 4

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

1

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

2

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

Wrap fiber filament tape

around the trailing edge

Apply spanwise strips of tape in the

center of the wing 4’’ from

the motor tray cutout

Apply strips of fiber

tape diagonally from the nose to the

outboard tip of the trailing edge

4”

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789

Figure 5

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

1234567890123456789012345678901212345678901234567890123456789

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

123456789012345678901234567890121234567890123456789012345678901

1234567890123456789012345678901212345678901234567890123456789012123456

1234567890123456789012345678901212345678901234567890123456789012123456

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012