Recommendations and Notes

To avoid injury or damage to electronic speed control, Do not plug the battery into the speed control

until all of the steps have been followed on page 14.

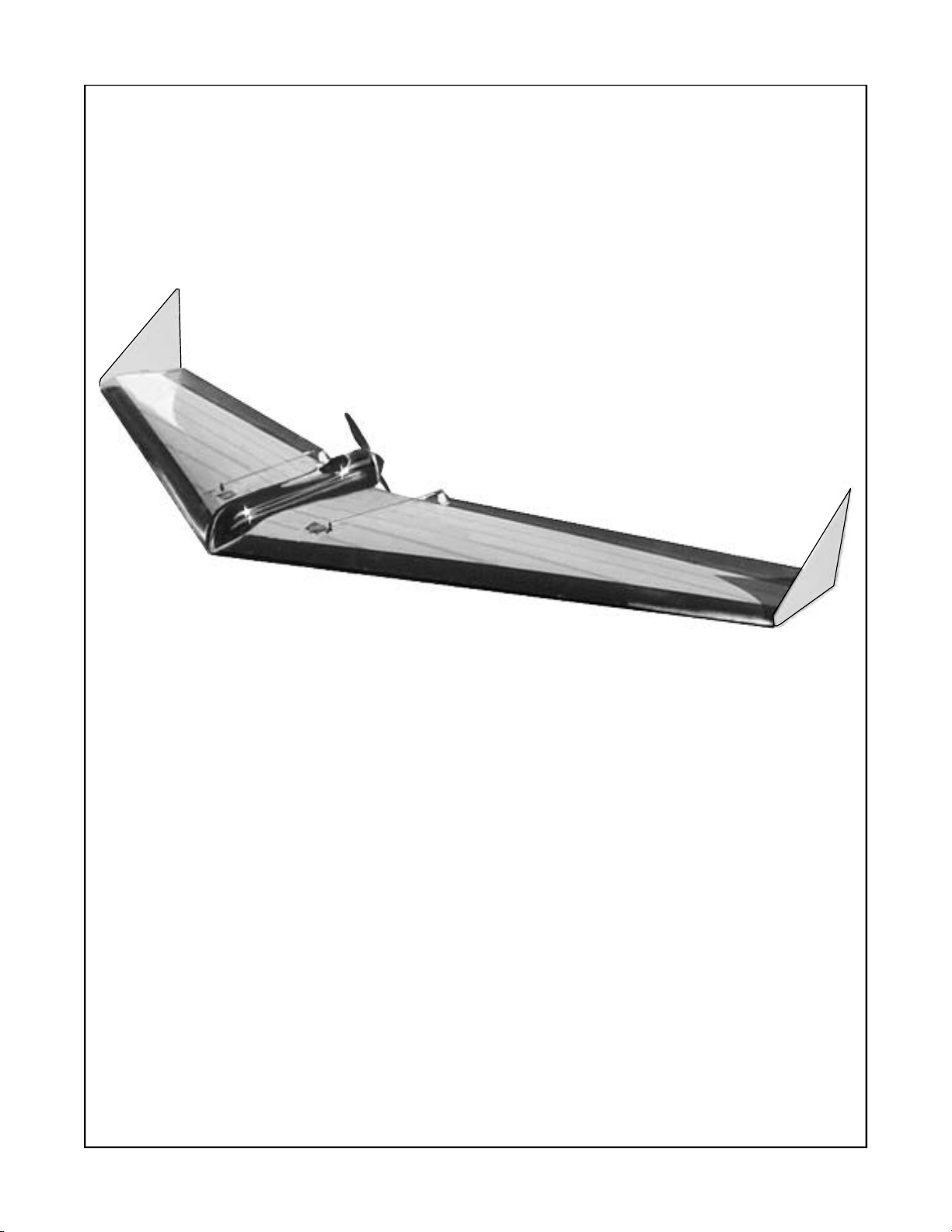

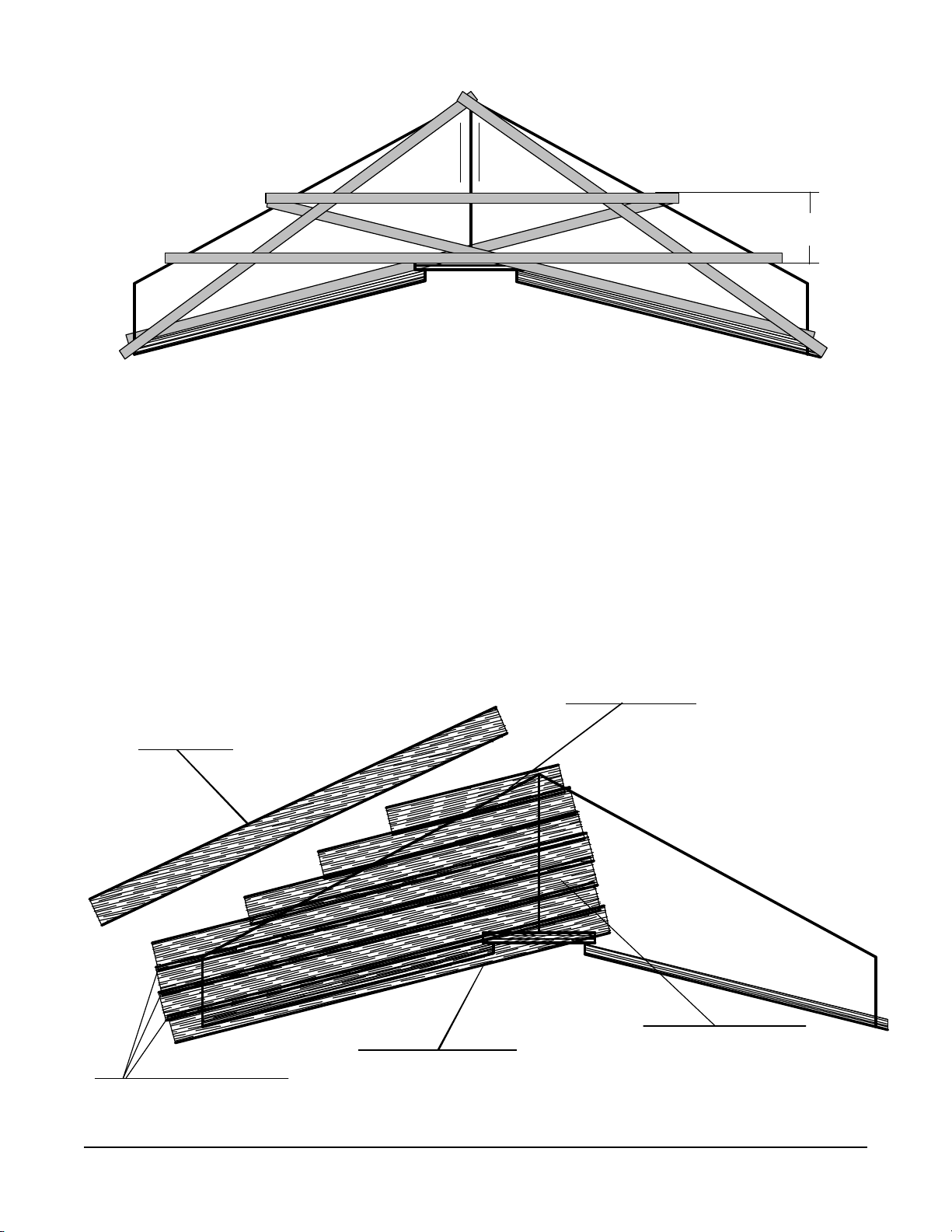

The ZAGI-400 is not a combat or bungie launch airplane. The design objectives

were to make a rugged low cost, light weight electric flying wing.

Read the entire manual before beginning construction!

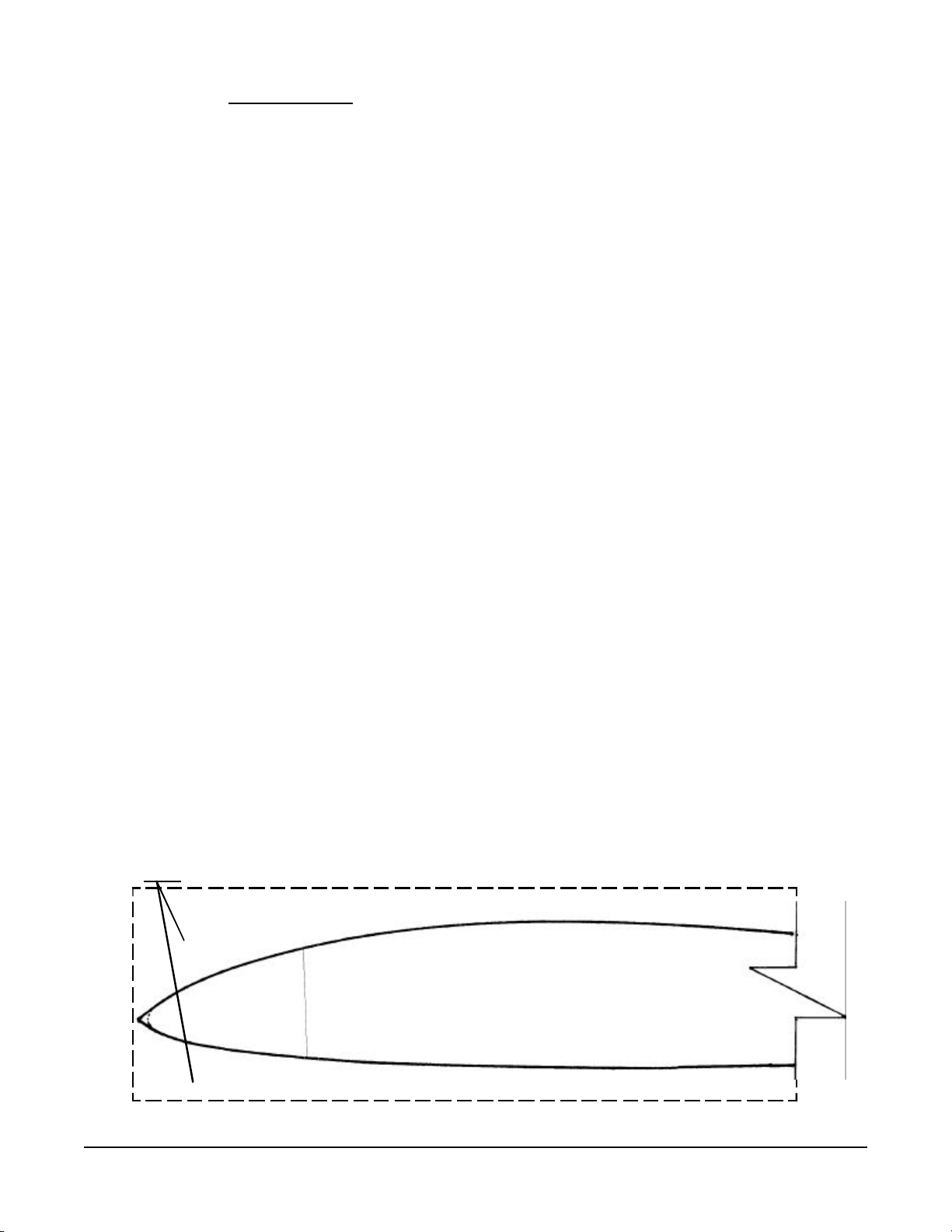

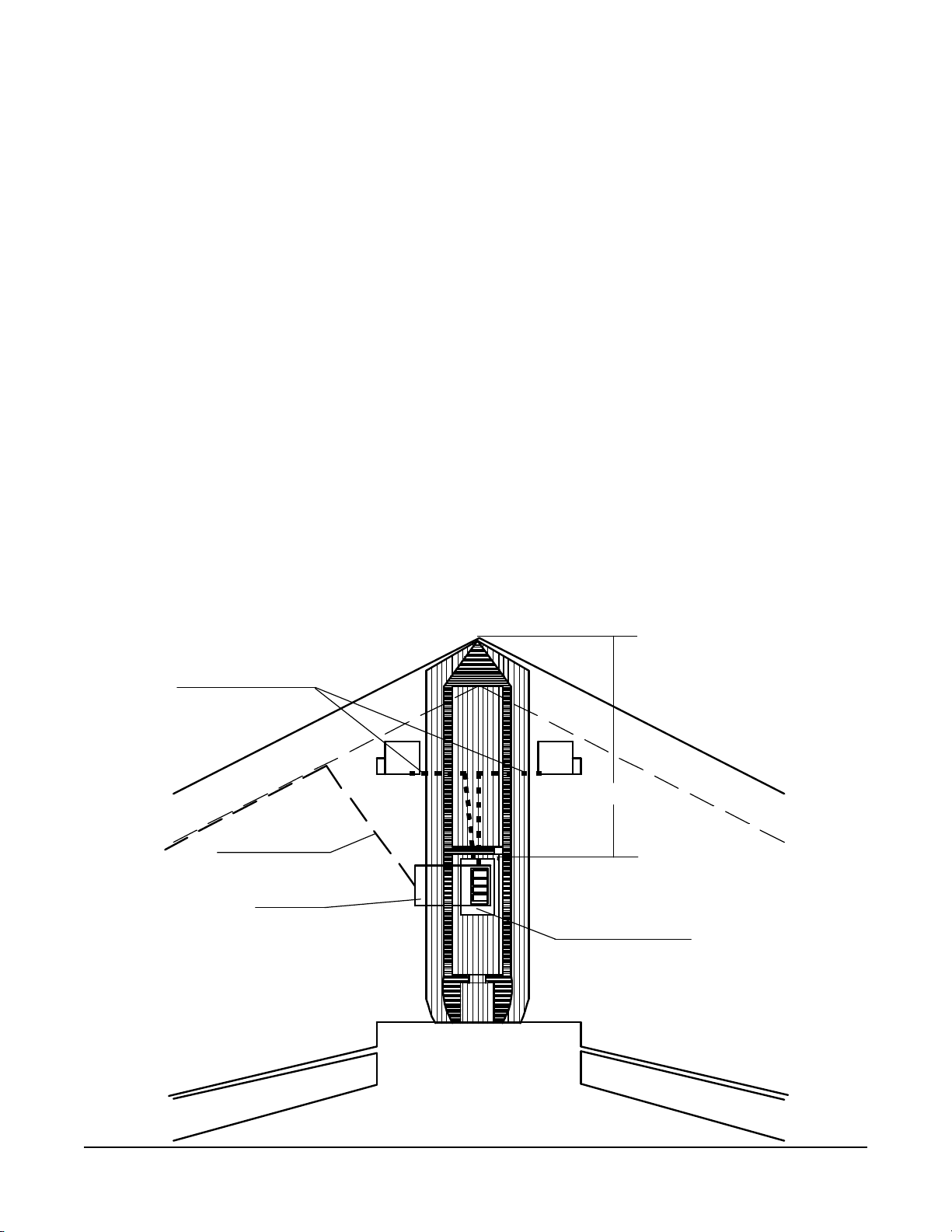

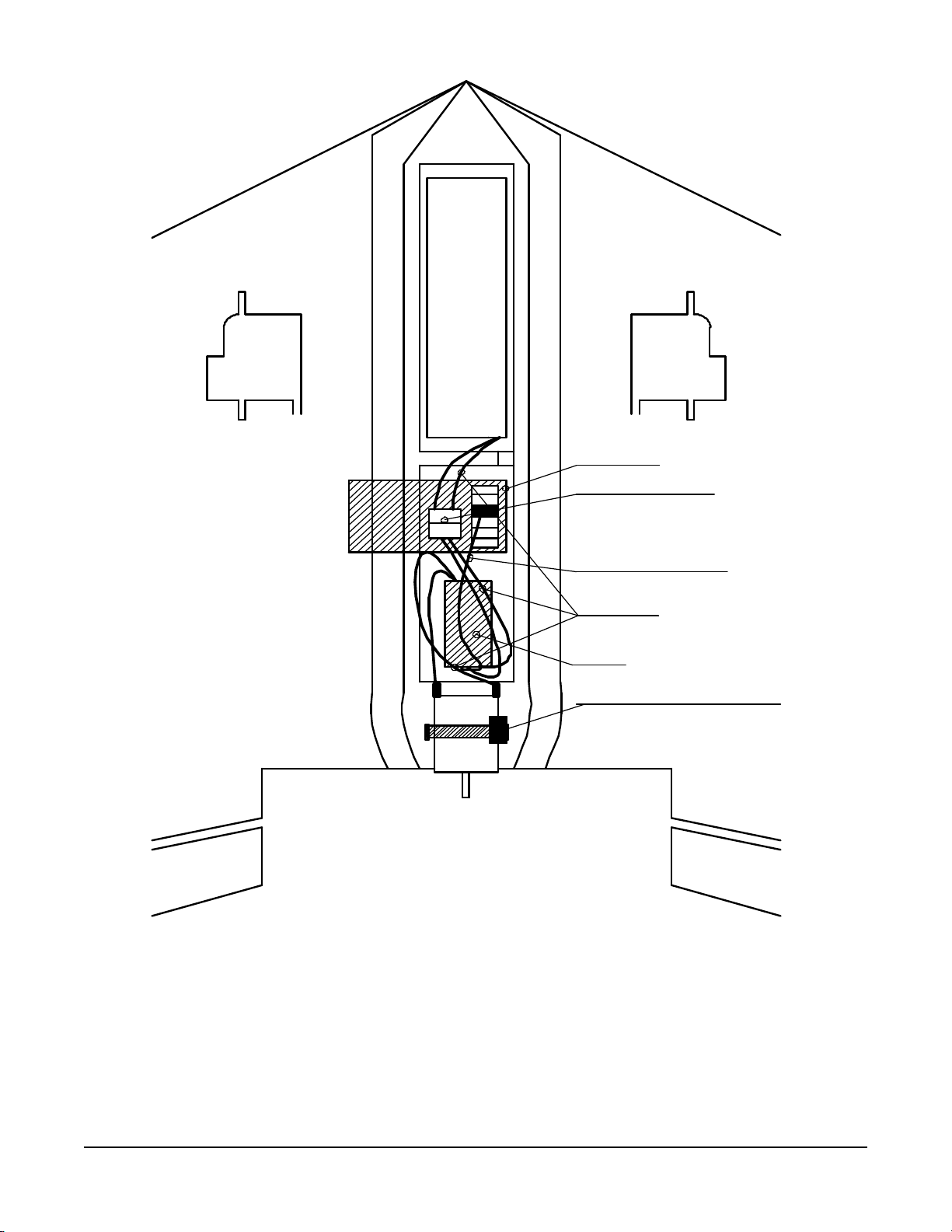

The target weight for the Zagi-400 is 19 oz. The airplane is designed to balance at 8”

measured back from the nose. In order to achieve these two objectives, a speed 400

motor, micro servos, and a 500 mAh 7 or 8 cell battery pack must be used. Any modifi-

cations, reinforcements or substitutions not described in this manual must be considered

carefully to maintain the correct weight and balance. If all of the procedures in this manual

are followed, the Zagi-400 will not need nose weight.

A separate battery is not required for the receiver and servos. They are powered by the

500 mAh battery through the Electronic Speed Control (ESC) which contains the Battery

Elimination Circuit (BEC). When the motor drains the battery there is still sufficient power

to control the plane.

Larger radio components are not recommended.

The manufacturer did not test any covering materials such as UltraCote, MonoKote,

Solarfilm, or any other iron-on materials. If an alternate covering material is chosen, test a

patch on the beds first. Lower heat will be necessary when covering the 1# white foam.

Do not cut into any part of the leading edge foam for the radio installation or nose weight.

Do not use polyester resin, solvents, or solvent-based paint on either type of foam.

Tools and materials needed:

Optional - a roll of contrasting color poly tape (see text)

90 degree square

Sanding block

150 to 320 grit sandpaper

X-Acto knife or Dremel

Round pencil or ball-point pen

Spray adhesive (3M Super 77 or similar)

3/4” fiber filament tape (2” filament tape optional - see text)

Solderingiron

page 2