Electronic Loads -1-

Table of Contents

Unpacking.............................................................................................................................3

Basic .....................................................................................................................................4

EPC42 ................................................................................................................................4

Selecting an external device ...............................................................................................4

Changing devices ...............................................................................................................6

Potential in electronic loads EL ...........................................................................................6

Safe operation conditions (SOC).........................................................................................7

EL300 ....................................................................................................................................8

Cell connections .................................................................................................................8

1. Full cell configuration ....................................................................................................8

2.a. Half-cell configuration - Cathode ..................................................................................9

2.b. Half-cell configuration -Anode ......................................................................................9

3. Partial cell configuration ................................................................................................10

4. Application with an additional power supply ..................................................................10

Built-in buffer amplifier......................................................................................................10

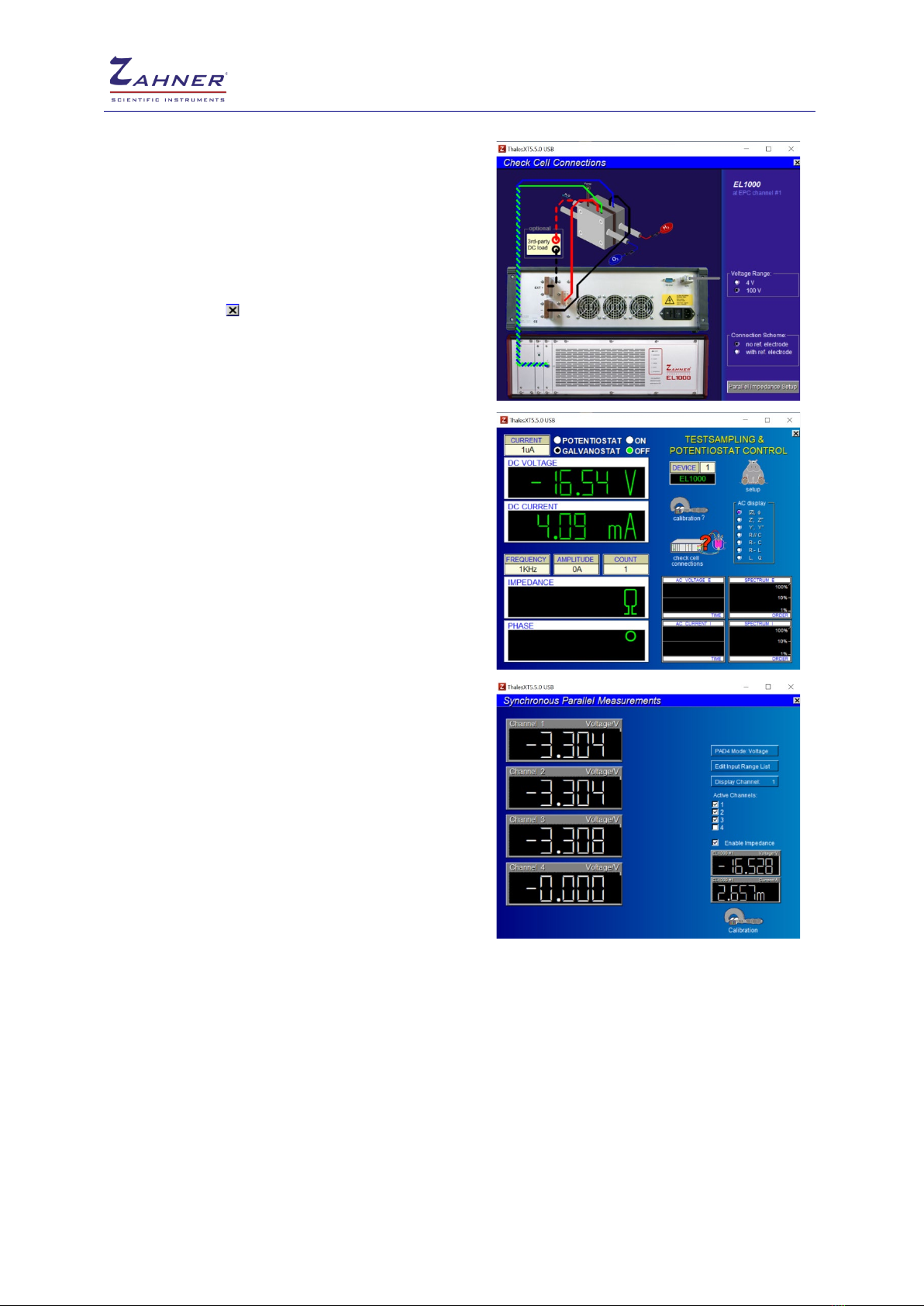

EL1000 ................................................................................................................................11

Measuring floating objects ................................................................................................11

EL1000 connection ...........................................................................................................11

Cell connections ...............................................................................................................11

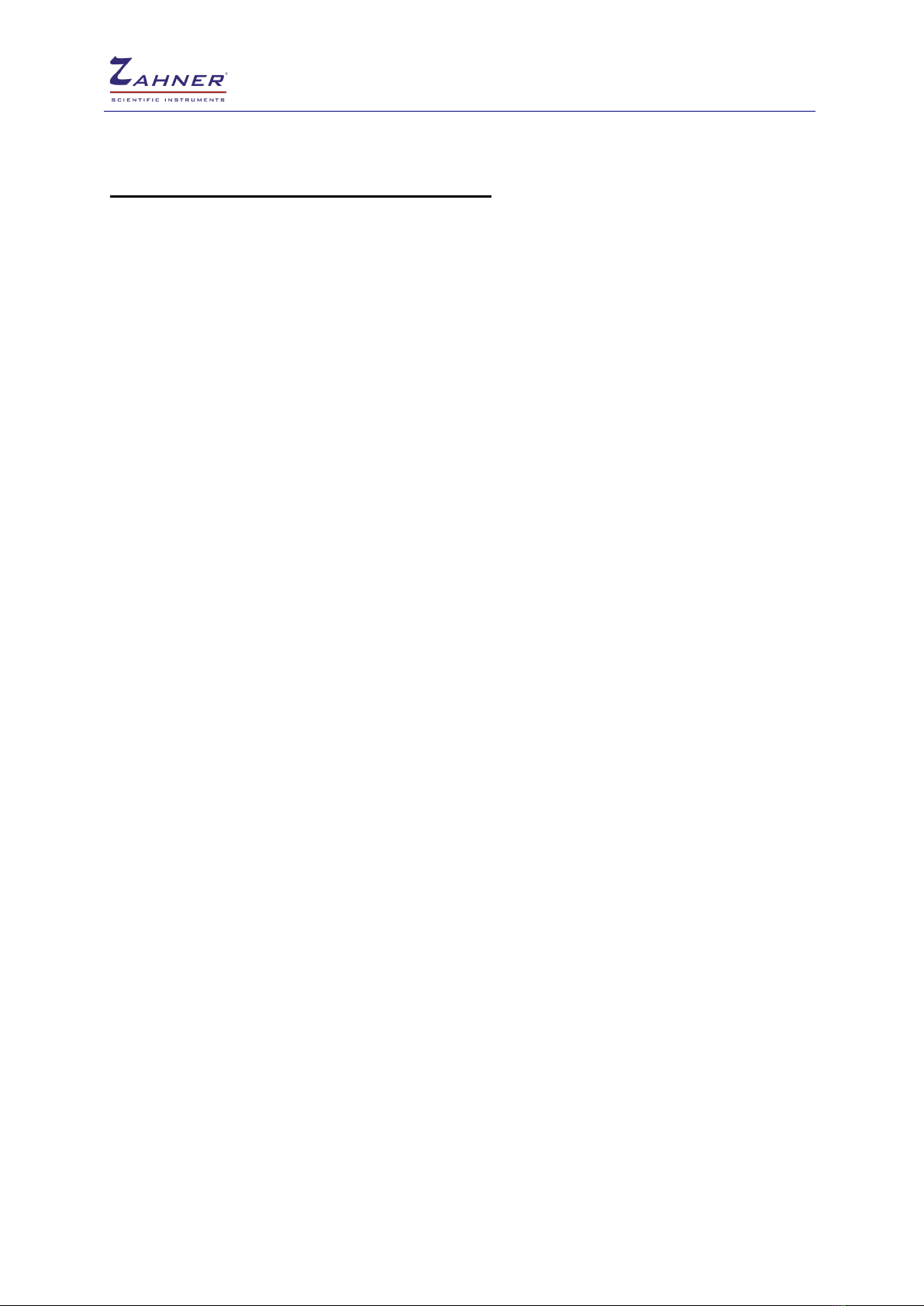

EL1000 operation steps ....................................................................................................12

1. Full cell configuration ..................................................................................................13

a. Current setting in EL1000 ................................................................................13

2.a. Half-cell configuration - Cathode ................................................................................14

2.b. Half-cell configuration - Anode ...................................................................................14

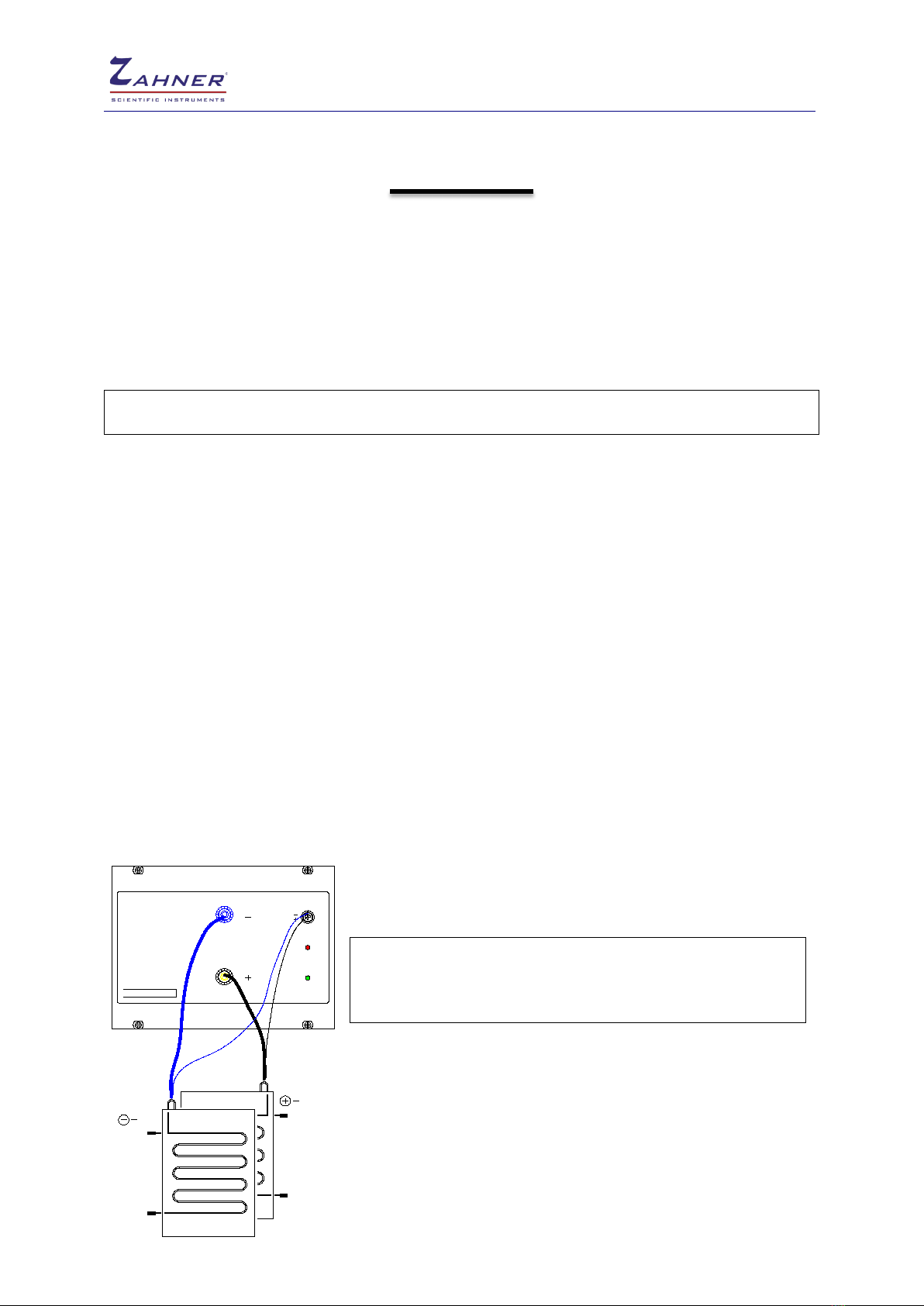

3. Partial cell configuration ............................................................................................15

a. PAD4 connections ...........................................................................................15

4. Application with an additional DC sink/load ...............................................................16

4.a. DUT connected with DC load and EL1000 .................................................................16

4.b. DUT connected with DC load and EL1000 (in parallel)...............................................17

5. Applications with an additional power supply .............................................................18

5.a. Charging batteries......................................................................................................18

5.b. Electrolysis of fuel cells ..............................................................................................19

5.c. Compensation of voltage drop (Zero Volt Option).......................................................20

6. Applications with an additional power supply (external input) ......................................21

Built-in buffer amplifier......................................................................................................23

Grounding circuit ..............................................................................................................23

Specifications....................................................................................................................24