Zanussi ZHC 951 Guide

Other Zanussi Ventilation Hood manuals

Zanussi

Zanussi ZHC 929 X Manual

Zanussi

Zanussi ZHT631B User manual

Zanussi

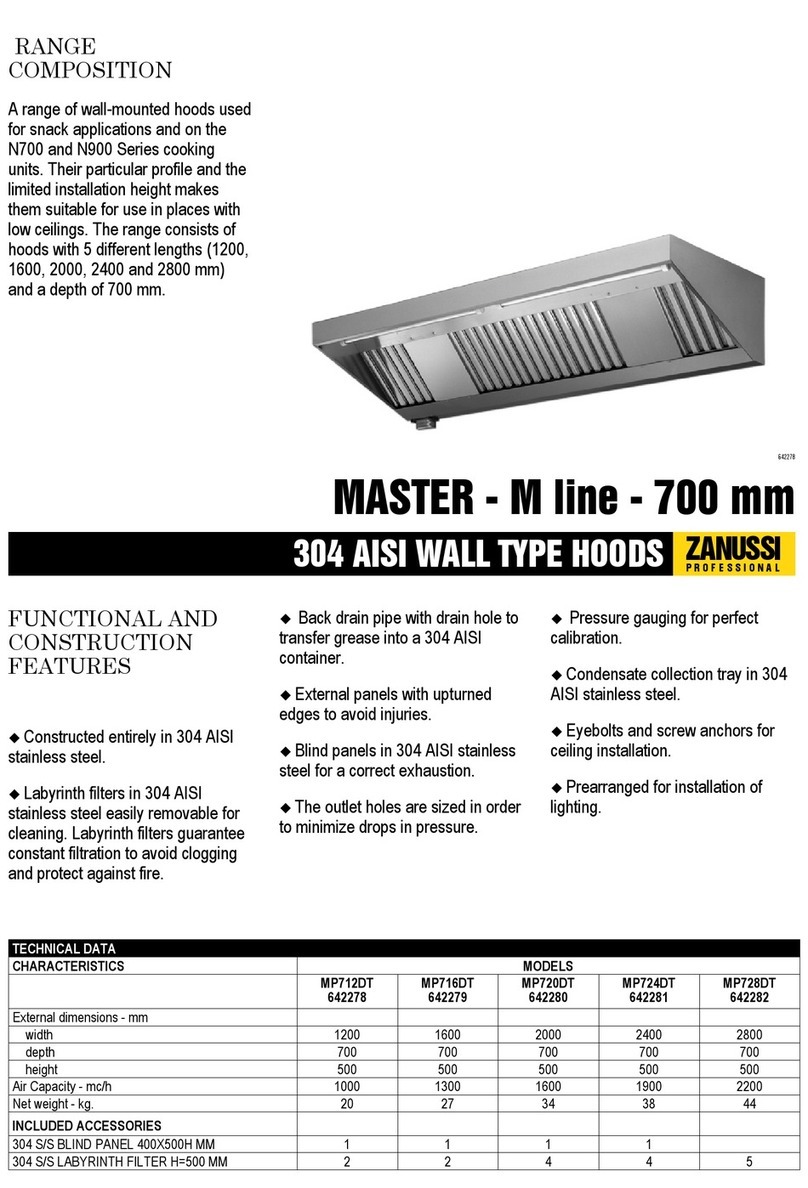

Zanussi Master 642278 User manual

Zanussi

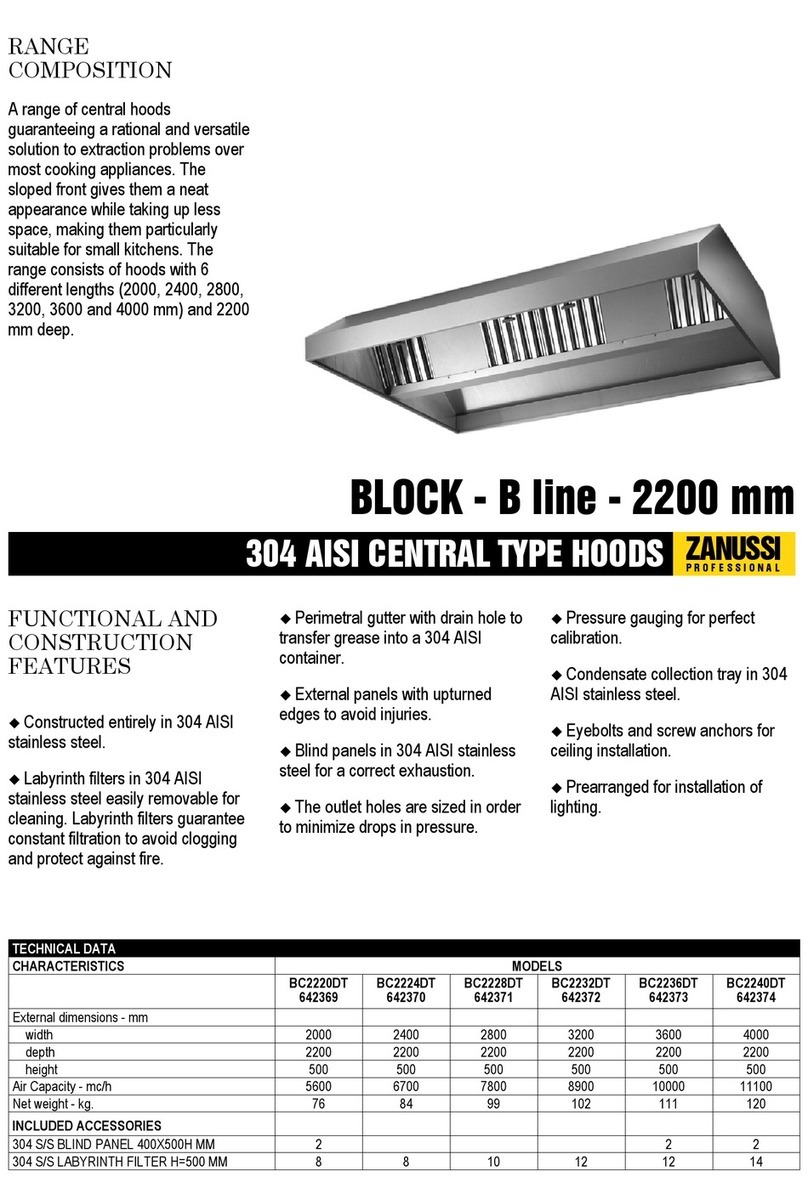

Zanussi Block 642369 User manual

Zanussi

Zanussi ZB 350 User manual

Zanussi

Zanussi ZHI622G User manual

Zanussi

Zanussi ZB 960 User manual

Zanussi

Zanussi ZHT800X User manual

Zanussi

Zanussi ZHC 700 User manual

Zanussi

Zanussi ZFT519X User manual

Zanussi

Zanussi ZHC 6121 User manual

Zanussi

Zanussi ZH 280 User manual

Zanussi

Zanussi ZHC92462XA User manual

Zanussi

Zanussi Professional Master 642081 User manual

Zanussi

Zanussi NH 9015 Guide

Zanussi

Zanussi ZH 9022 User manual

Zanussi

Zanussi ZHC 930 X Manual

Zanussi

Zanussi ZHT 510 Manual

Zanussi

Zanussi ZHG713G User manual

Zanussi

Zanussi Supertredil 641266 User manual