You may obtain additional copies of this manual from

our web site at www.zarebasystems.com, or contact

Zareba Systems at: 906 5th Ave. E, Ellendale, MN

56026, 1-800-272-9877.

IMPORTANT SAFETY

INFORMATION

General Safety Information

Vehicular gates are large heavy objects. Automatic gate

openers provide a convenient way to open and close

the gates. Since the gate system and its components

exert a high level of force to open and close the gate,

they can be dangerous, causing severe injuries and

death to you and others.

Your safety and the safety of others depend on the

owner and users of this system to read, understand,

and follow the information and instructions in this man-

ual. Save this safety information for future use.

Safety overview checklist

WARNING – To reduce the risk of injury or death:

• Use this operator with single or double swing gates.

• READ AND FOLLOW ALL INSTRUCTIONS.

• Never let children operate or play with gate controls.

Keep the remote control away from children.

• Always keep people and objects away from the gate.

NO ONE SHOULD CROSS THE PATH OF THE MOVING

GATE.

• Test the gate operator monthly. The gate MUST

reverse on contact with a rigid object or stop when an

object activates the non-contact sensors. After adjust-

ing the force or the limit of travel, retest the gate oper-

ator. Failure to adjust and retest the gate operator

properly can increase the risk of injury or death.

• KEEP GATES PROPERLY MAINTAINED. Read the owner’s

manual. Have a qualified service person make repairs

to gate hardware if needed.

• The entrance is for vehicles only. Pedestrians must use

a separate entrance.

• SAVE THESE INSTRUCTIONS

• Remember that the Zareba Automatic Gate Opener

must only be installed on gate systems meeting the

requirements of the application.

• Ensure that you are using the correct opener for the

type and size of gate, its frequency of use and the

class rating.

5

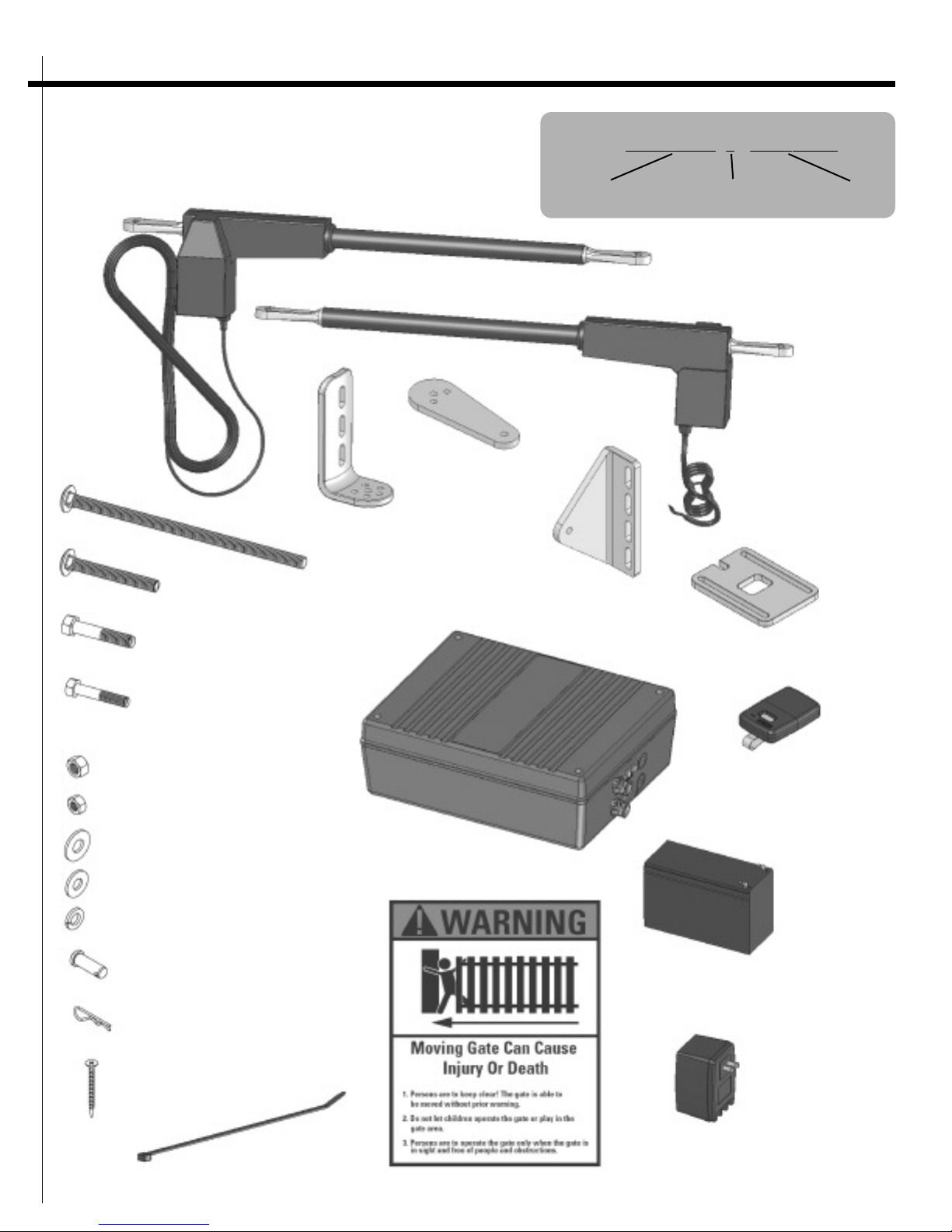

Thank you for purchasing the Zareba Automatic Gate

Opener.

Your Zareba Automatic Gate Opener is designed for

years of trouble free performance. It will provide you

with a comfortable, safe, hassle-free way to access your

property.

This Automatic Gate Opener is designed to work on sin-

gle or dual swing gates. Each individual gate can be up

to 14 feet long and weigh up to 450 pounds. Your gate

opener will work on a variety of gate types such as iron,

tubular, chain link, vinyl, etc. It is not recommended to

use an automatic gate opener on a solid fence due to

wind resistance. Depending on the strength of the wind

and the obstruction sensing, your gate may not operate

properly.

Your Zareba Automatic Gate Opener can be opened

and closed in a variety of ways. Primarily, you will use

your remote transmitter (included with your unit) to

open or close the gate. However, the gate can also be

opened with a hardwired button, an automatic vehicle

sensor, a keypad, or built-in vehicle transmitter systems.

These accessories are discussed later in this manual. The

gate can also be closed with the hardwired button or

keypad. In addition it can be closed automatically using

a time delay that is set in the control box.

Your Zareba Automatic Gate Opener is designed to pro-

vide for safe operation. One of the most important fea-

tures of your gate opener is obstruction sensing. Your

gate opener includes an adjustment for setting the sen-

sitivity of the obstruction performance. When there is

an obstruction that prevents the gate from opening or

closing, the gate will immediately stop and reverse

direction. If the obstruction is removed the gate may be

activated to continue its path from where it stopped. If

the obstruction is not removed, the gate opener will

sound an alarm and will not operate again until the

gate opener system is reset.

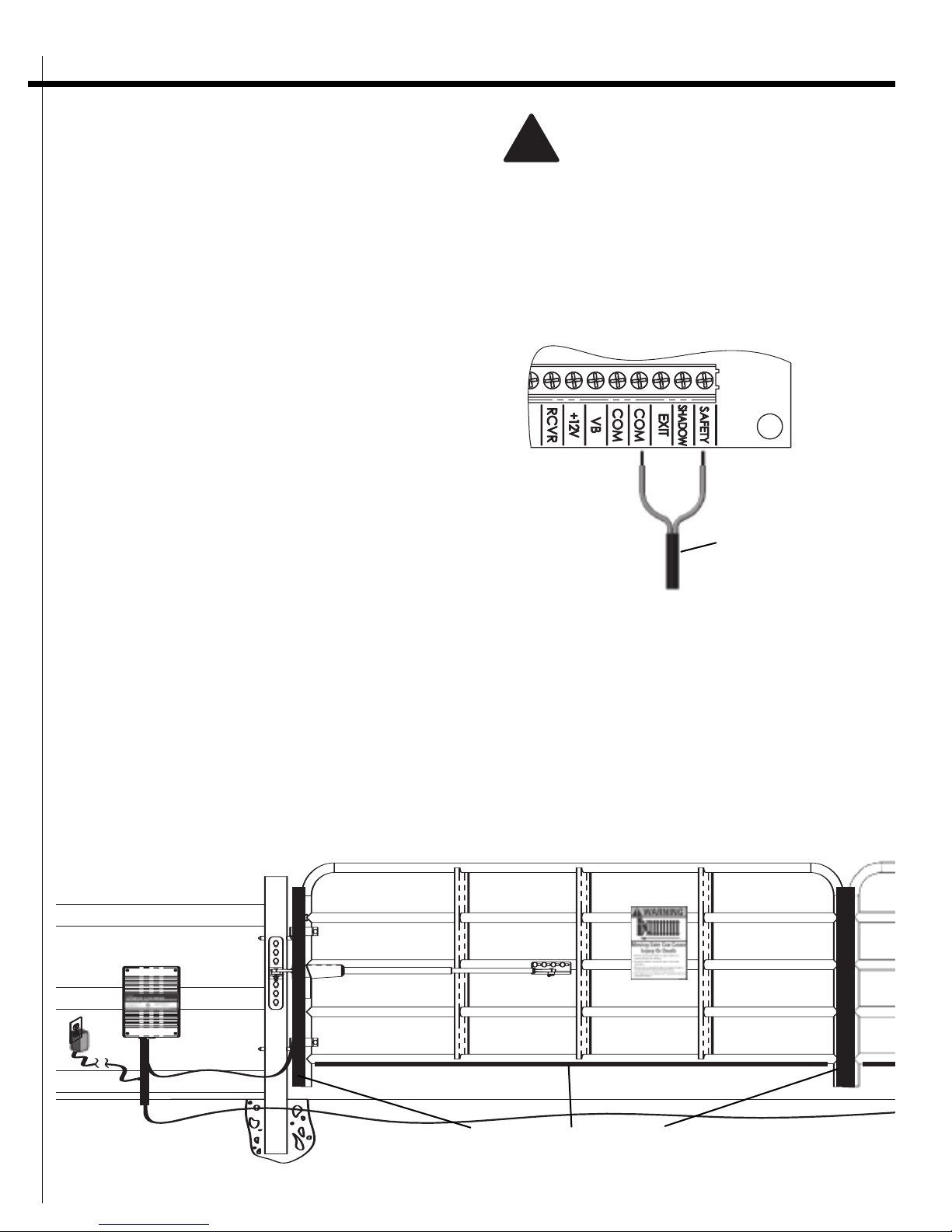

There are a number of accessories that can be installed

with your gate opener that maximize your benefit to

owning the system. The accessories include additional

transmitters, keypad, pin lock, solar panel, in-ground

vehicle sensor, and others. Please see Gate Opener

Accessories at end of this manual.

AN INTRODUCTION TO

AUTOMATIC GATE

OPENERS