G550 Automatic Gate Opener Installation Manual

6

IMPORTANT SAFETY

INFORMATION

General Safety Information

Vehicular gates are large heavy objects. Automatic gate

openers provide a convenient way to open and close

the gates. Since the gate system and its components

exert a high level of force to open and close the gate,

they can be dangerous, causing severe injuries and

death to you and others.

Your safety and the safety of others depend on the

owner and users of this system to read, understand, and

follow the information and instructions in this manual.

Save this safety information for future use.

Safety overview checklist

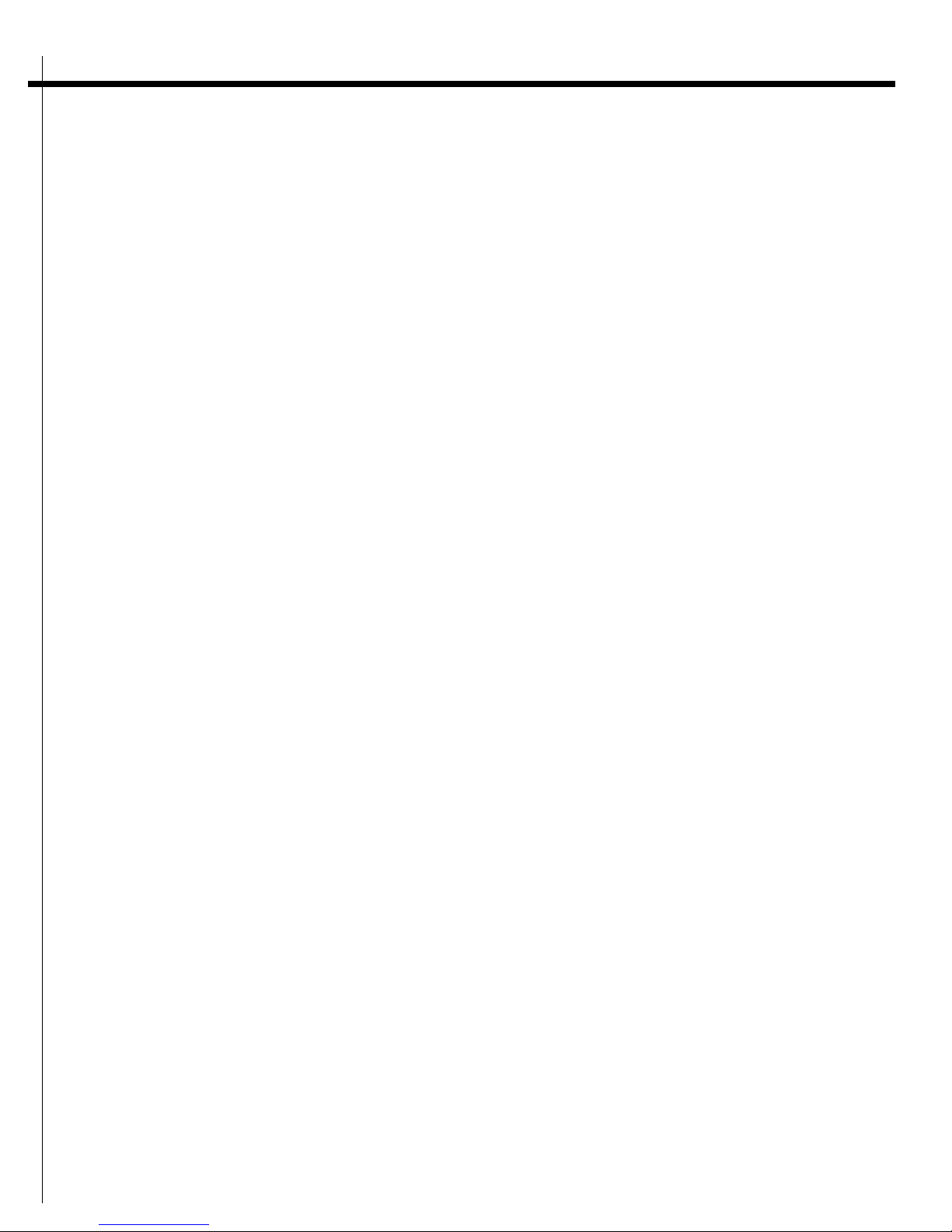

WARNING – To reduce the risk of injury or death:

• Use this operator only with single swing gates.

• READ AND FOLLOW ALL INSTRUCTIONS.

• Never let children operate or play with gate controls.

Keep the remote control away from children.

• Always keep people and objects away from the gate.

NO ONE SHOULD CROSS THE PATH OF THE MOVING

GATE.

• Test the gate operator monthly. The gate MUST

reverse on contact with a rigid object or stop when an

object activates the non-contact sensors. After adjust-

ing the force or the limit of travel, retest the gate

operator. Failure to adjust and retest the gate operator

properly can increase the risk of injury or death.

• KEEP GATES PROPERLY MAINTAINED. Read the own-

er’s manual. Have a qualified service person make

repairs to gate hardware if needed.

• The operator is intended for installation only on gates

used for vehicles. Pedestrians must be supplied with a

separate access opening. The pedestrian access open-

ing shall be designed to promote pedestrian usage.

Locate the gate such that persons will not come in

conatct with the vehicular gate during the entire path

of travel of the vehicular gate.

• SAVE THESE INSTRUCTIONS

• Remember that the Zareba Automatic Gate Opener

must only be installed on gate systems meeting the

requirements of the application.

• Ensure that you are using the correct opener for the

type and size of gate, its frequency of use and the

class rating.

• Ensure that the gate and gate opener installation com-

ply with applicable local codes.

• Contact local fire and law enforcement to arrange

emergency access procedures.

• Keep people, animals, and property away from the

gate area. Do not let children play in or near the gate

area.

• Use caution with moving parts to avoid injuring fin-

gers or hands.

• Consider installing contact sensors, or non-contact

sensors to provide additional safety and protection

against entrapment.

• Never activate your gate opener until you ensure that

the area is clear of people, pets, or other obstructions.

Watch the gate until it stops.

• Do not drive forward until the gate stops completely.