Topens BK800 User manual

VER 23a

C030619

Belt Sliding Gate Opener

User’s Manual

Model:

TOPENS Website

www.topens.com

Email: support@topens.com

BK800

★Please read and follow all warnings, precautions and instructions before

installation and use.

★Periodic checks of the opener are required to ensure safe operation.

★Save this manual.

CONTACT US:

Visit: www.topens.com

Please record the product model, your email address etc.

in the spaces provided below. Refer to this list when contacting TOPENS

for technical service or assistance with your automatic gate opener.

Where did you purchase? (Amazon.com; Amazon.ca: Amazon.co.uk, Amazon.de; Other, Please

Specify)

Order#

Product Model

Purchase Date

Full Name

Phone#

Email Address (VERY

IMPORTANT)

Street Address, Apartment /Unit, City, State /Province, Zip Code

Country/Region

Approximate Gate Weight

(pounds; kg: Other. Please

Specify)

Approximate Gate Length

(feet; meter; Other. Please

Specify)

Did you purchase any

accessories? (Please list

below)

Issue Details

Email Us: support@topens.com

Call: +1 (888) 750 9899 (Toll Free USA & Canada)

Table of Contents

Check Your Gate before Installation ................................................................................................................1

General Safety ................................................................................................................................................. 1

Preparation for Installation............................................................................................................................... 2

Parts List...........................................................................................................................................................4

Accessories Parts (Included in some models, refers to the actual package)..................................................4

OptionalAccessories Parts List (Available at TOPENS Store)........................................................................5

Replacement Parts........................................................................................................................................... 5

Technical Specifications & Features................................................................................................................6

Installation Overview........................................................................................................................................ 6

Installation of the Opener................................................................................................................................. 7

Manual Operation............................................................................................................................................. 7

Installation of belt and brackets........................................................................................................................8

Installation of the Magnets.............................................................................................................................10

Connecting of Power Supply...........................................................................................................................11

Connecting of the Control Board.....................................................................................................................11

Setting of the Control Board........................................................................................................................... 13

Test the Reversing Sensitivity........................................................................................................................14

How to Program or Erase the Remote...........................................................................................................15

How to Use the Remote to Operate Your Gate Opener ................................................................................ 15

Wireless Keypad Programming...................................................................................................................... 16

Troubleshooting.............................................................................................................................................. 16

Maintenance...................................................................................................................................................18

1

Thank you for purchasing our sliding gate opener. We are sure that the products will be greatly satisfying as

soon as you start to use it.

The product is supplied with a user’s manual which encloses installation and safety precautions. These

should be read carefully before installation and operation as they provide important information about safety,

installation, operation and maintenance. This product complies with the recognized technical standards and

safety regulations.

Check Your Gate before Installation

General Safety

WARNING! An incorrect installation or improper use of the product can cause damage to persons,

animals or properties.

• Scrap packing materials (plastic, cardboard, polystyrene etc.) according to the provisions set out by current

standards. Keep nylon or polystyrene bags out of children’s reach.

• This product was exclusively designed and manufactured for the use specified in the present

documentation. Any other use not specified in this documentation could damage the product and be

dangerous.

• The factory declines all responsibility for any consequences resulting from improper use of the product, or

use which is different from that expected and specified in the present documentation.

• Do not install the product in explosive atmosphere.

• The factory declines all responsibility for any consequences resulting from failure to observe Good

Technical Practice when constructing closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

• Disconnect the electrical power supply before carrying out any work on the installation. Also disconnect

any buffer batteries, if fitted.

• Fit an omnipolar or magnetothermal switch on the mains power supply, having a contact opening distance

equal to or greater than 3,5 mm.

• Make sure a residual current circuit breaker with a 30mA threshold is fitted before the power supply mains.

• Check that earthing is carried out correctly: connect all metal parts for closure (doors, gates etc.) and all

system components provided with an earth terminal.

• Fit all the safety devices (photocells, electric edges etc.) which are needed to protect the area from any

2

danger caused by squashing, conveying and shearing.

• Position at least one visible indication device, and fix a Warning sign to the structure.

• The factory declines all responsibility with respect to the automation safety and correct operation when

other supplier’s components are used.

• Only use original parts for any maintenance or repair operation.

• Do not modify the automation components, unless explicitly authorized by the factory.

• Instruct the product user about the control systems provided and the manual opening operation in case of

emergency.

• Do not allow persons or children to remain in the automation operation area.

• Keep radio control or other control devices out of children’s reach, in order to avoid unintentional

automation activation.

• The user must avoid any attempt to carry out work or repair on the automation system, and always request

the assistance of qualified personnel.

• Anything which is not expressly provided for in the present instructions is not allowed.

•Before installing the gate opener, check that all moving part as well as the sliding gate is in good

mechanical condition, correctly balanced and opens and closes properly.

•Save these instructions for future use.

Preparation for Installation

Before proceeding to your opener installation, check if your gate structure is in accordance with the current

standards, especially as follows:

The gate sliding track is linear and horizontal, and the wheels are suitable,the gate should be mounted and

moving freely. Check that the structure is sufficiently strong and rigid, Make sure that the gate is plumb and

level. The fence posts must be mounted in concrete. The gate does not bind or drag on the ground.

• The opening and closing gate stops are positioned.

WARNING: Remember that control devices are intended to facilitate gate operation, but can not

solve problems due to any defects or deficiency resulting from failure to carry out correct installation or

maintenance. Take the product out of its packing and inspect it for damage. Should it be damaged, contact

your dealer. Remember to dispose of its components (cardboard, polystyrene, nylon, etc.) according to the

current prescriptions.

Refer to the following Figures for gate installation.

3

In sake of safety, a positive stop must be mounted on the two end of ground track.

4

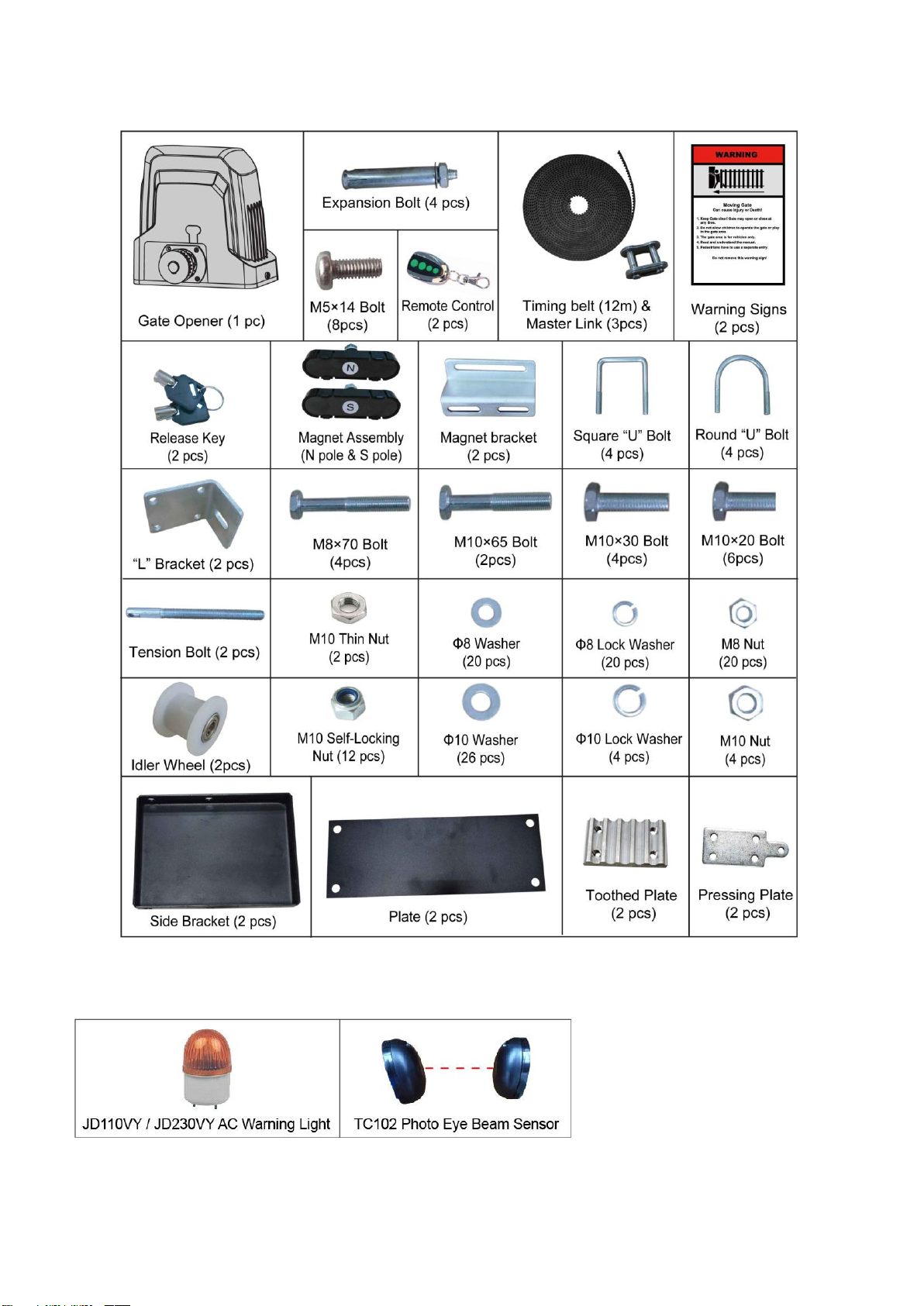

Parts List

Accessories Parts (Included in some models, refers to the actual package)

5

Optional Accessories Parts List (Available at TOPENS Store)

M12 Remote Control

ERM12 External

Receiver

TC186-R WiFi

Smartphone Remote

Control with Camera

TC188 Universal

Wireless and Wired

Keypad

TKP3 Wireless Keypad

TC175P Wired Keypad

HLR01 HomeLink

Remote Control Kit

TC173 Wireless Push

Button

TC147 Wall Push Button

TC148 Waterproof Wall

Push Button

TRF3 Reflection

Photocell Sensor

TC102 Photo Eye Beam

Sensor

JD110VY / JD230VYAC

Warning Light

TEW3 Vehicle Sensor

Exit Wand

Replacement Parts

ACPYMJ7C Control

Board (120V)

ACPYMJ8C Control

Board (230V)

PYMJ-CKG Limit Switch

WARNING: Changes or modifications not expressly specified by this user manual, TOPENS could void

the warranty of this equipment.

6

Technical Specifications & Features

Specifications

Power input:

110~120V/60Hz or 220~240V/50Hz

Motor voltage:

120VAC or 230VAC

Rated power:

350W

Gate moving speed:

20 cm/s (8 in/s)

Max gate weight:

800kg (1800lbs)

Max gate length:

12m(40ft)

Environmental conditions:

-20℃~ +50℃(0°F to 120°F)

Protection class:

IP44

Features:

·Midway mode.

·Quick selection for the gate open/close direction

·Reliable rolling code technology for remote control

·Emergency release key in case of power failure

·Stop in case of obstruction during gate opening

·Reverse in case of obstruction during gate closing

·Built in adjustable auto-close (1-99 seconds)

·Built in max. Motor Running Time (MRT) for

multiple safety protection (90 seconds)

·Reliable electromagnetism limit for easy

adjustment

·Can be equipped with a wide range accessories

·Easy to install, and minimum maintenance

requirement

·Get the desired belt tension by adjusting the

tension bolts

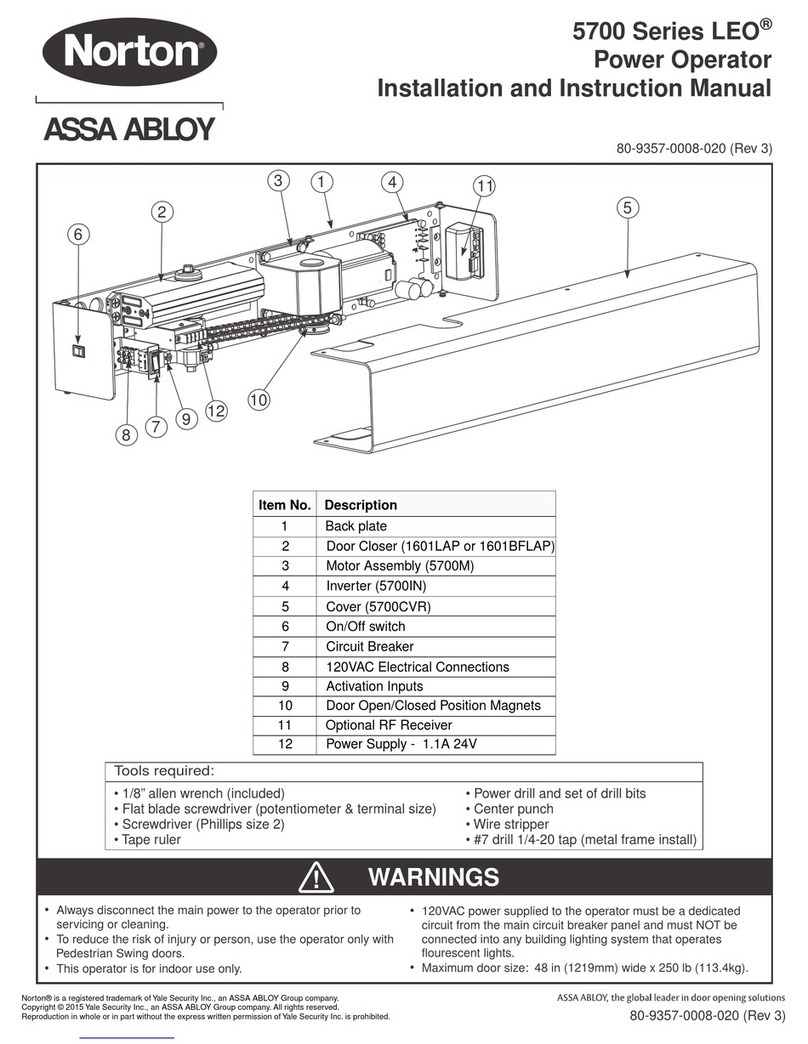

Installation Overview

7

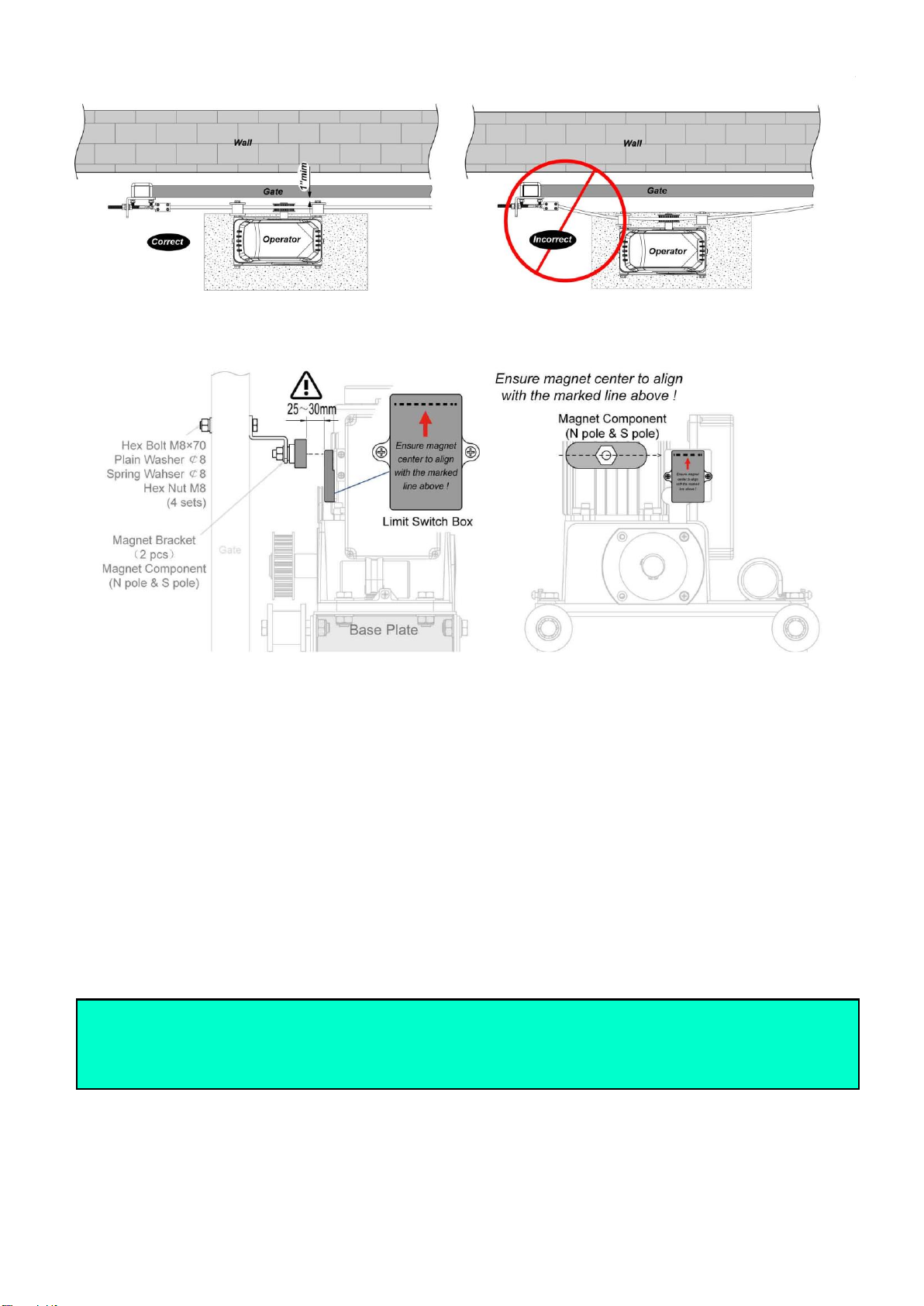

Installation of the Opener

Caution:

*Be sure that the opener is installed in a level

and paralleled position. Improper installation

could result in property damage, severe injury,

and/or death.

* Before starting installation, ensure that there is

no point of friction during the entire movement

of the gate and there is no danger of derailment.

* Ensure that the safety side rollers are present.

Necessary Tools: The following tools may be

necessary to install the Gate opener. You will need

screwdrivers, an electric drill, wire cutters and a wire

stripper, a socket set, and possibly access to a

welder.

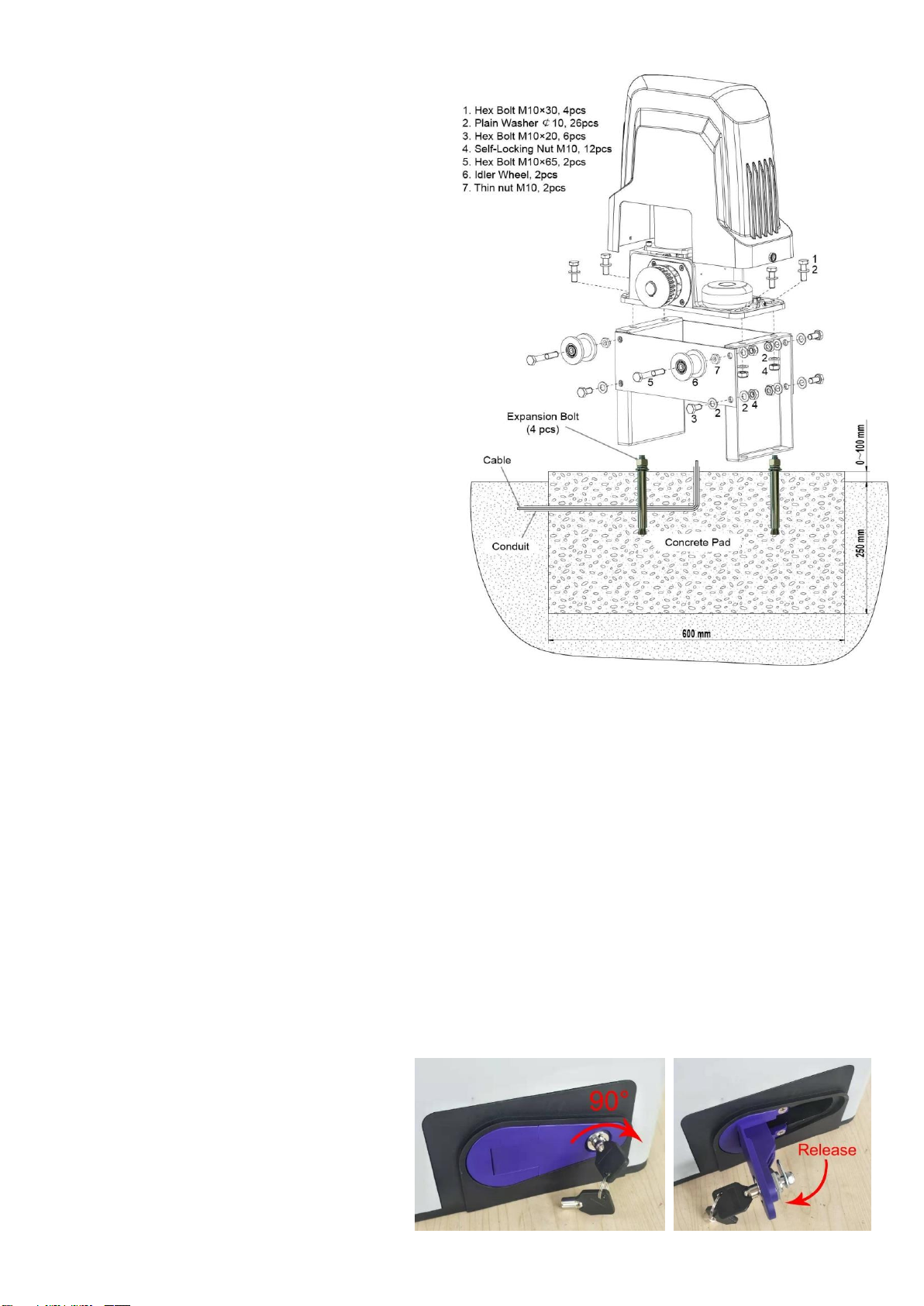

When install the opener, you should build a

concrete pad to support the base plate of opener in

order to maintain proper stability.

The installation proceeds are as follows:

1.Assemble the Base Plate and fix the Opener to

the Base Plate.

2.Dig a hole for a concrete pad which should be

approximately 60 x 32 x 35cm (24〞x 13〞x 14〞).

It may protrude 10 cm (4”) above ground and 25 cm

(10”) in depth underground. Increase the pad height if necessary to protect the system from flooding, heavy

snow etc.

3. Prepare one or more conduits for the electrical cables before pour concrete. Remember that cable

conduits have to pass through the hole on the base.

4. Pour concrete and before it starts to harden, check that it is parallel to the gate leaf and perfectly level.

5. Mark the position of four expansion anchors according to the position of mounting hole on the base plate.

Double check your marking, move the base plate and drill the 4 holes using a 14mm (9/16”) masonry bit. Put

the 4 expansion anchors (provided) into the holes and firmly tighten.

6. Mount the base plate to the concrete Pad and firmly tighten, enabling the opener is firmly secured

on the concrete pad during the whole gate travel.

Manual Operation

You can open the gate by manual when power failure. And the opener should be put in the manual

(emergency release) position before fitting the belt, installing the opener and limit switch. The process is as

follows:

Insert the Release Key and turn it in

clockwise 90°, then pull the release handle in

clockwise 90° to disengage the clutch

between the gear shaft and motor. Now the

opener is in the manual operation.

8

Installation of belt and

brackets

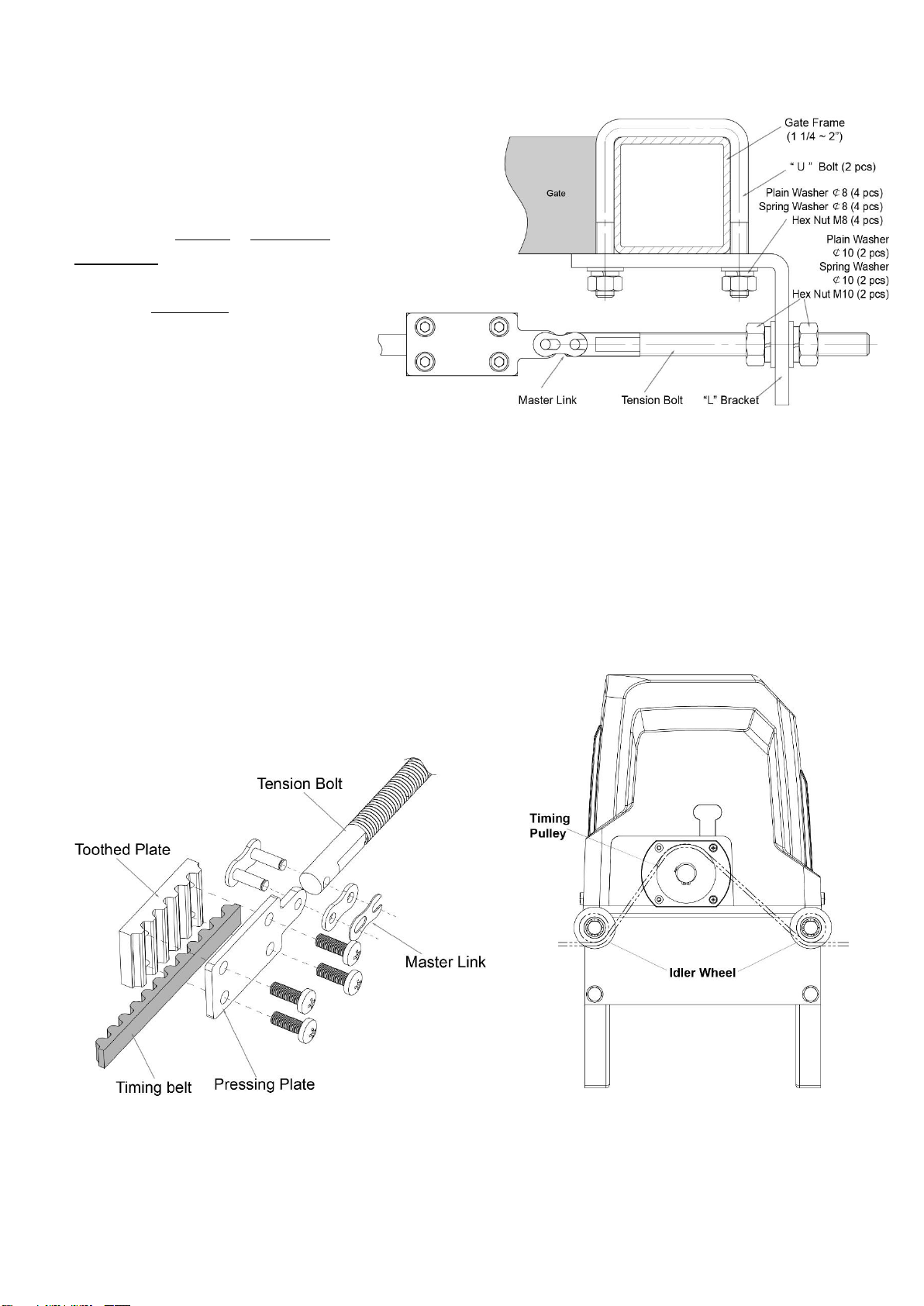

1. Belt Brackets

1). Please refer to below brackets figure,

which shows “U”bolt, “L”bracket and

tension bolt.

Use the “U”bolts (square or round) to

attach the “L”brackets to gate frame.

2). If Both the square bolts and round

bolts are not fit for the gate frame, use

the appropriate bolts to attach the

brackets to gate frame.

2. How to install the belt

1). Place the belt around the top of the timing pulley and under the idler wheels.

2). Connect a tension bolt to one end of belt by using toothed plate, pressing plate, screws and master link.

Then insert the tension bolt to the L bracket and fix them by washers and nuts temporarily. (Nuts will be

further adjusted for a proper belt tension later)

3). Cut off the unwanted length of belt by heavy duty cutting pliers.

4). Connect another tension bolt with another end of belt by using toothed plate, pressing plate, screws and

master link. Then insert the tension bolt to another L bracket and fix them by washers and nuts temporarily.

(Nuts will be further adjusted for a proper belt tension later)

5). Make sure that the belt is line up exactly with the middle position on all wheels.

6). Set a little tight belt tension by adjusting two tension

bolts of the both end.

9

6). The belt brackets must be mounted to the same height as the belt under the idler wheels.

7). Make sure there is 1”distance at least between the wheels and the gate after you position the base plate.

10

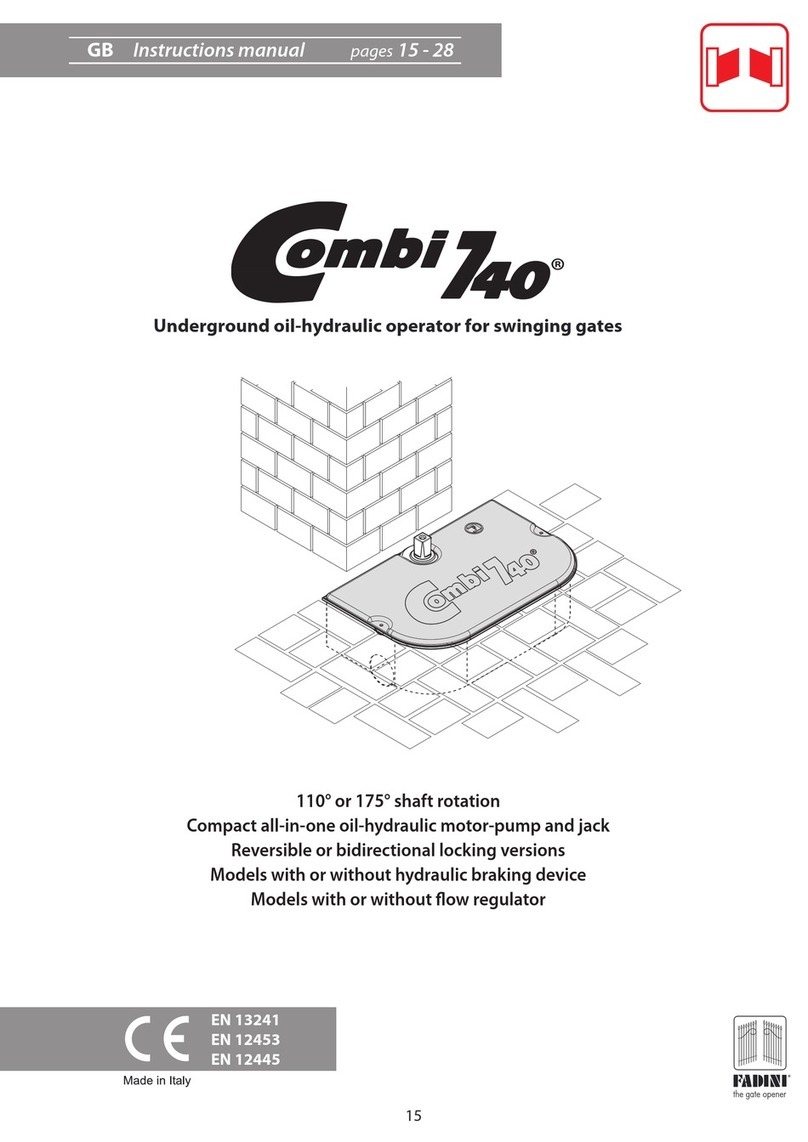

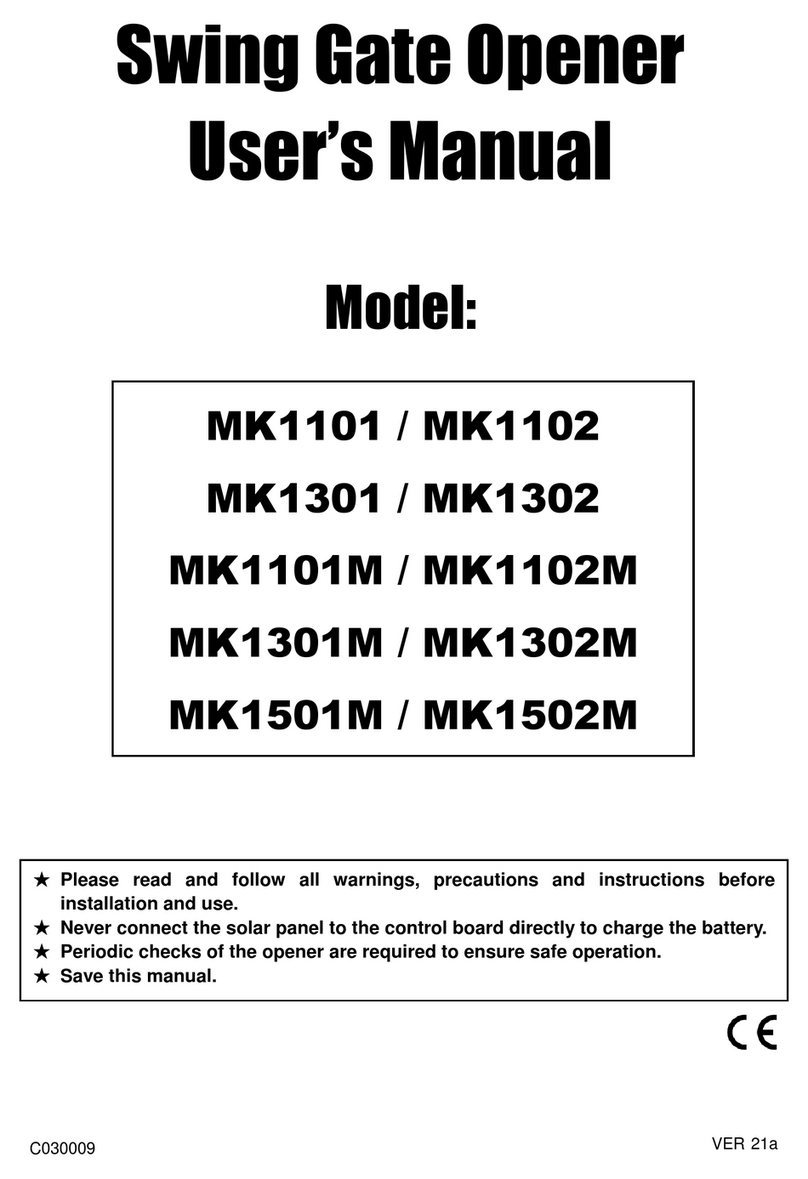

Installation of the Magnets

Before install limit switch, make sure the gate opener is put in manual operation. (the clutch connected with

gear shaft is disengaged) and the mains power supply is disconnected. Position the two Magnet

Components approximately on the gate and move the gate by hand to fix them in place.

Fit magnets bracket

Push the gate fully closed by hand. Locate and install the magnet bracket so that the opener will stop at the

desired close position when the close limit switch approaches it.

Push the gate fully open by hand. Locate and install the magnet bracket so that the opener will stop at the

desired open position when the open limit switch approaches it.

The magnet component with S pole must be installed at left side and the magnet component with N

pole must be installed at right side from the view inside of property.

Ensure magnet center to align with the marked line above !

The magnets should be 25~30mm (1-1.2”) away from the Limit Switch Box. If it is too near or too far, the

switches will fail to work. Adjust the position of the magnets until the positions of the opening and closing

meet the requirement.

Warning: Improper magnets installation may cause the gate crash into end barrier,

which is very dangerous !

11

Connecting of Power Supply

WARNING: NEVER connect the gate opener to the power outlet before

all the installations have been done.

The power supply cord should be at least 3×0.75mm2(3C×18AWG). Connect the

live wire and neutral wire to the “L” (1) and “N” (2) terminal of the control board

respectively; and connect the earth wire to “PE”.

Connecting of the Control Board

1. Motor

The BLACK wire of the motor should be connected into the “3” terminal.

The YELLOW wire of the motor should be connected into the “4” terminal.

The RED wire of the motor should be connected into the “5” terminal.

12

2. Limit Switches

The YELLOW wire of the limit switches should be connected into the “8”terminal.

The BLACK wire of the limit switches should be connected into the “9”terminal.

The RED wire of the limit switches should be connected into the “10”terminal.

3. Warning Light (Included in some models, refers to the actual package)

One wire of the warning light should be connected into the “6”terminal, another should be connected into

the “7”terminal.

4. Start Capacitor

The two wires of the start capacitor should be connected into the “4”terminal and “5”terminal.

5. Photocell Beam System (PBS) (Included in some models, refers to the actual package)

Use a 2-core cable to connect the “+ ~”terminal of the photocell’s emitter to the “11”terminal, the “- ~”

terminal to the “13”terminal. Also the “+ ~”and “- ~”terminals of the photocell’s receiver should be

connected to the “11”and “13”terminals in parallel.

Use another 2-core cable to connect the “COM”terminal of the receiver to the “13”terminal, the “NC”

terminal to the “12”terminal.

6. Reflection Photocell Sensor (optional)

The “AC10-25V/DC12-30V”terminals of the reflection photocell sensor should be connected to the “11” and “13”

terminals, no matter the polarity.

The “NC”terminal should be connected to the “12”terminal.

The “COM”terminal should be connected to the “13”terminal.

7. Wired Keypad (12VDC) (Optional)

The RED wire of the wired keypad should be connected into the “11” terminal.

The BLACK wire of the wired keypad should be connected into the “13” terminal.

The PURPLE wire of the wired keypad should be connected into the “13” terminal.

The BLUE wire of the wired keypad should be connected into the “14” terminal.

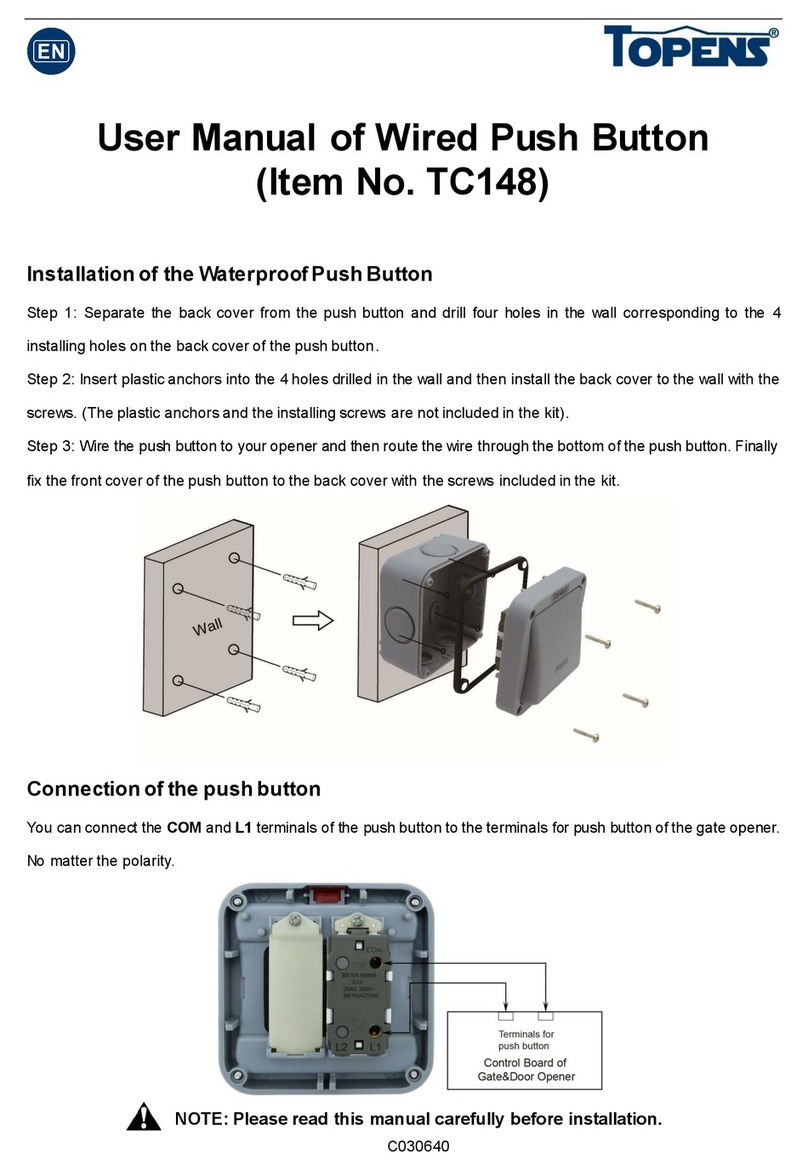

8. Push Button (Optional)

The push button should be wired to the “13” and “14” terminals. The gate operator works alternately by

pushing the button (open-stop-close-stop-open).

9. External receiver (optional)

The RED wire of the external receiver should be connected into the “11” terminal.

The BLACK wire of the external receiver should be connected into the “13” terminal.

The BROWN wire of the external receiver should be connected into the “14” terminal.

10. HomeLink Remote Control Kit (optional)

The “1”terminal should be connected to the “13”terminal.

The “2”terminal should be connected to the “14”terminal.

The “DC+”terminal should be connected to the “11” terminal.

The “DC-”terminal should be connected to the “13”terminal.

11. Exit Wand (optional)

13

The BLACK wire of the exit wand should be connected into the “15”terminal.

The BLUE wire of the exit wand should be connected into the “16”terminal.

The RED wire of the exit wand should be connected into the “11”terminal.

The GREEN wire of the exit wand should be connected into the “13”terminal.

The sensitivity adjustment board should be wired to the GREEN wire and the YELLOW wire of the wand. No

matter the polarity.

Setting of the Control Board

WARNING: Ensure the gate opener is Power Off when you make any adjustment of the gate

opener. Keep away from the gate during you set the gate opener system in case of the unexpected

gate moving. Carefully adjust the DIP switches to avoid the risk of machine damage and injury or

death. Always ask the help of professional technician /electrician if you have any question.

1. DIP Switches

The DIP switches are used to set the running

time of the motor in pedestrian mode,

enable/disable auto close function of the gate

operator and fast change the open/close

direction which is determined by the position

of the gate operator installed.

DIP Switch #1–#2: Running time of the

motor in Midway Mode

DIP Switch #1: ON –2 Seconds OFF –0

DIP Switch #2: ON –4 Seconds OFF –0

NOTE: The midway mode function would be disabled if both DIP switches are turned off. Factory

default setting is disabled. The midway mode could be activated by pressing button B of the remote

control when the gate is in the full closed position.

DIP Switch #3: Auto close function enabled/disabled

DIP Switch #3: ON –auto close function enabled

OFF –auto close function disabled

E.g. Running time of the operator in midway mode is 2 seconds.

E.g. Auto close function of the opener has been enabled. Factory default setting is disabled.

14

Important Note: When the auto close function is enabled, the photocell sensor is highly

recommended to be installed with the gate opener for safety.

DIP Switch #4: Left/Right open

2. Potentiometers

Potentiometer A and B are used to adjust the stall force and auto close time of the gate operator separately.

Turn potentiometer A clockwise to increase the stall force, and turn it counter-clockwise to decrease the

stall force.

WARNING: Photocell is highly recommended to be installed with the gate opener as entrapment

protection for safety when you set stall force to maximum.

Turn potentiometer B clockwise to increase the auto close time, and turn it counter-clockwise to decrease

the auto close time, the auto close time could be adjusted gradually from 1 to 99 seconds.

Test the Reversing Sensitivity

For the sake of safety, it is very important to test the reversing sensitivity as soon as the control board set is

finished.

The reversing sensitivity adjustment is inverse correlation with stall force adjustment in potentiometer A. In

other word, the stall force level is higher; the reversing sensitivity level is lower.

Put an immobile object along the gate path, and then operate the gate to strike it during the close cycles.

The gate must reverse as soon as object is struck with it. If the gate doesn’t reverse, please increase the

reversing sensitivity by turning the potentiometer A in counter-clockwise direction. (Turning the stall force

potentiometer toward to MIN position to increase the reversing sensitivity)

Note 1: If the sensitivity setting is too higher, the gate will stop or reverses very easy by itself while

there is little obstruction or resistance such as strong wind or heavy snow sometimes.

Note 2: Always check the gate reversing function every each time of control board set or restart after

power off.

15

How to Program or Erase the Remote

The remote MUST be programed to the opener BEFORE OPERATING. Please follow the steps to

program the remote.

Activate the opener only when gate is in full view, free of obstruction and properly adjusted. No

one should enter or leave gate area while gate is in motion. DO NOT ALLOW CHILDREN to

operate push button or remote. DO NOT ALLOW CHILDREN TO PLAY NEAR THE GATE.

If you purchase additional remote controls, the gate opener must be programmed to accept the

new remote code.

If you lose one of any remote control, please erase

and reprogram all other remote controls to have a

new code for safety.

Program the remote

Press and release the LNSW button, the LEARN LED light

will be on, then press the key A or B on the remote two

times in 2 seconds, between the two times HOLD ON

FOR A MOMENT, the LEARN LED light will flash for 4

seconds. Now the remote has been programmed

successfully.

Erase all the remote codes

Press and hold the learn button until the LEARN light is off. Now all remote codes have been erased.

Max. 8 remotes can be programmed for the opener. An External Receiver (optional) allows up to

250pcs remotes to be programmed for the opener. TOPENS ERM12 Universal External Receiver is

available at TOPENS Store.

TOPENS ERM12 Universal External Receiver is also compatible with other brand swing gate

opener, sliding gate opener and garage door opener.

How to Use the Remote to Operate Your Gate Opener

Each remote has four buttons, from top to bottom are separately A, B, C and D. You may use this remote to

operate as many as 4 sets TOPENS swing gate openers or 1 set TOPENS sliding gate

opener and 2 sets TOPENS swing gate openers.

1. Use this remote to only operate TOPENS swing gate opener A, B, C and D four

buttons share same function once they are programmed with

TOPENS swing gate opener. You may choose any button to program it with our swing

gate opener. Every press of the button is able to active the gate opener to work

alternately (open-stop-close-stop-open).

2. Use one remote to operate TOPENS swing gate opener & sliding gate opener at the

same time

All of TOPENS sliding gate opener have midway mode. Button B is designed to realize

midway function (refer to more details in our TOPENS sliding gate opener manual). So it is must program

button A with sliding gate opener, while you may program either C button or D button with TOPENS swing

gate opener.

16

Wireless Keypad Programming

You can follow the below steps to program wireless keypad to the opener. Press the LNSW button until the

LEARN LED is ON,and then releases the button. Then press "OK" button on keypad and LEARN LED will

flash for 3 seconds and then be OFF which indicates the keypad has been programmed successfully. You

can use the default password “888888”to operate the opener after programming. You can press “PIN”“8 8 8

8 8 8”and then press “OK”to confirm to operate the opener.

Also you can change the password of the keypad follow the below steps. Press “PIN”and then input the six

digits old password and then press ”PIN”again, the LEARN LED will be ON. Input the six digits new

password and then press the “PIN”to confirm the new setting, LEARN LED will flash for 3 seconds and then

be OFF which indicates the password has been changed successfully. You can press “PIN”“6 digits new

password”and then press “OK”to confirm to operate the opener.

NOTE: Every step for pressing button during program must be finished within 1 second to ensure successful

programming.

Troubleshooting

Have a multimeter to check voltage and continuity. Use caution when checking high voltage terminals.

Symptom

Possible Solution(s)

The opener does not

run.

1. Check the input voltage of the control board. It should be local AC

electricity.

2. Check the fuse in the control board. Replace the fuse if it was burnt out.

3. Ensure the remote control has been programmed to the control board

before operating.

4. The thermal protector is working because the high temperature after long

working time. Please wait for 20 minutes to let the motor become cold.

5. Check the installing position of the limit magnets. The opener would not

run if both of the limit switches are activated by one magnet.

17

6. Check the limit switch. Remove the wire connection of the limit switch

which is connected to the 8#, 9#, and 10# terminals of the control board and

then use a jumper wire to short the 3 terminals together to try it again.

Replace the limit switch if the motor could run in both directions.

7. Check the control board. Replace the control board as necessary.

Remote control does

not work.

1. The indicator light of remote control is not on. Check the battery in your

remote control. Replace the battery as necessary.

2. The distance you use the remote is too far away from the opener. Try it

again closer.

3. Remote control is not suitable for receiver. After making sure the codes are

correct, erase remote controls and then re-program the codes in the device.

4. Check the control board. Replace the control board as necessary.

The gate starts but it

is immediately stop or

reverse

1. Check the wire connection of hall sensor board with the main control

board.

2. The opening force or closing force is adjusted too small. Turn the

Potentiometer Ato increase the force.

3. Disconnect the gate from the gate opener and check that the gate slides

freely without any binding.

4. Check the control board. Replace the control board as necessary.

The gate opens, but

stops and will not

return.

1. Check the installing position of the magnets. The opener would not run if

both of the limit switches are activated by one magnet.

2. Check the limit switch. Remove the wire connection of the limit switch

which is connected to the 8#, 9#, and 10# terminals of the control board and

then use a jumper wire to short the 3 terminals together to try it again.

Replace the limit switch if the motor could run in both directions.

3. Check the control board. Replace the control board as necessary.

The gate can open,

but fails to close.

1. Photocell is obstructed. Remove obstruction.

2. Check the limit switch. Remove the wire connection of the limit switch

which is connected to the 8#, 9#, and 10# terminals of the control board and

then use a jumper wire to short the 3 terminals together to try it again.

Replace the limit switch if the motor could run in both directions.

3. Check the control board. Replace the control board if necessary.

The gate will open

automatically instead

of close after the auto

close time

Ensure the DIP 4# has been set correctly according to the installation for

“Left Open”or “Right Open”

The motor runs but

the gate doesn’t

move.

Ensure the clutch for emergency release is adjusted properly and is not

slipping.

Table of contents

Other Topens Gate Opener manuals

Topens

Topens DK1000 User manual

Topens

Topens CK700 User manual

Topens

Topens CF800 User manual

Topens

Topens DKC2000 User manual

Topens

Topens AT1202 User manual

Topens

Topens RK700 User manual

Topens

Topens LC1100 User manual

Topens

Topens CASAR HJ4021 User manual

Topens

Topens RK990 User manual

Topens

Topens CK500 User manual

Topens

Topens RK1200 User manual

Topens

Topens DKC500 User manual

Topens

Topens KD702 User manual

Topens

Topens Casar MT8012 User manual

Topens

Topens AT6132 User manual

Topens

Topens MK1101 User manual

Topens

Topens CK2500 User manual

Topens

Topens TC148 User manual

Topens

Topens AT6131 User manual

Topens

Topens EK700M User manual