Contents

1 About this operation manual.............................................................................................2

1.1

Explanation of symbols in this operation manual......................................................... 3

2 Scope of delivery.................................................................................................................. 4

3 Safety........................................................................................................................................5

3.1

General safety instructions............................................................................................................ 5

3.2

Warnings on the Air-Con Service Station....................................................................................7

3.3

Safety devices................................................................................................................................. 7

4 Proper use.............................................................................................................................. 8

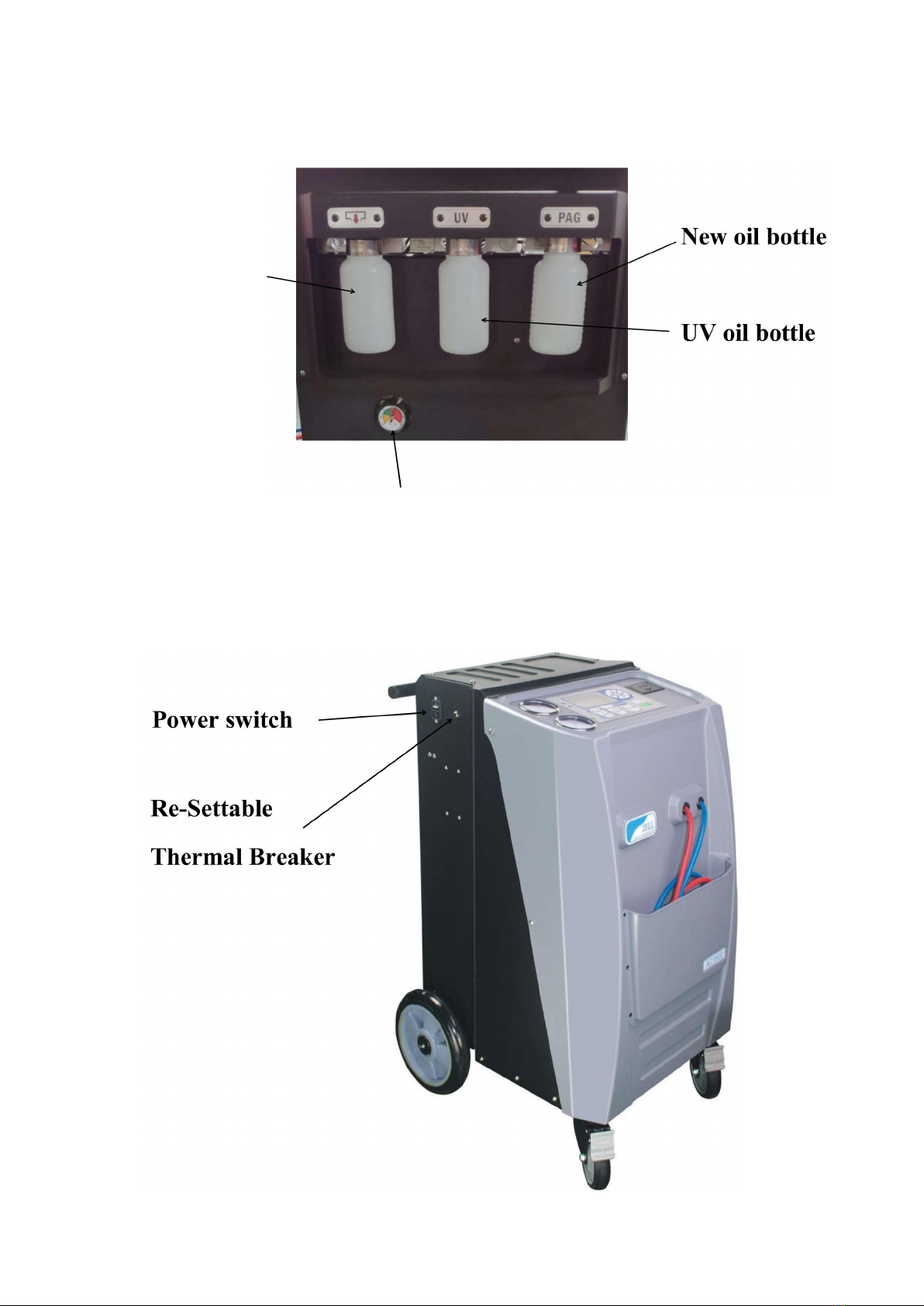

5 Overview of the Air-Con Service Station........................................................................9

6 First start up......................................................................................................................... 12

6.1

Setting up and switch up..............................................................................................................12

6.2

Putting into the bottles for new oil...............................................................................................13

6.3

Filling up the internal refrigerant container................................................................................ 13

7 Operation...............................................................................................................................19

7.1

Recovery..........................................................................................................................................20

7.2

Vacuum and vacuum test.............................................................................................................24

7.3

Oil injection.....................................................................................................................................27

7.4

UV injection...................................................................................................................................... 30

7.5

Recharge..........................................................................................................................................34

7.6

Fully auto..........................................................................................................................................39

7.7

Weight scale verification................................................................................................................. 44

7.8

Record print...................................................................................................................................... 46

7.9

Weight scale and Pressure sensor zero........................................................................................47

8. Service tasks.......................................................................................................................52

8.1

Inner tank refill............................................................................................................................... 52

8.2

Language select............................................................................................................................52

8.3

Weight unit..................................................................................................................................... 53

8.4

Other service................................................................................................................................53

9. Disposal................................................................................................................................54

9.1

Disposing of used fluids............................................................................................................... 54

9.2

Disposing of packaging material................................................................................................54

10 Trouble shooting............................................................................................................... 55

11 Technical data.................................................................................................................... 56

12 Spare Part list.....................................................................................................................56