1

Contents

1 About this service manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.1 ZELL hotline

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . 2

2 Safety warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3 Electronic diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .4

3.1 Main power diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . ........ . . . . . . . . . . . . . . . . . . . . . . . ..4

3.2 Main control board diagram

. . . . . . . . . .. . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . .. 4

4 Flow chart. . . . . . . . . . . . . . . . . . . . . . . . . . . ........ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Overall layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . 5

4.2 eneral flow chart

. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . ... . . . . . . . . . . . 6

4.3 Recovery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................................ . . . 6

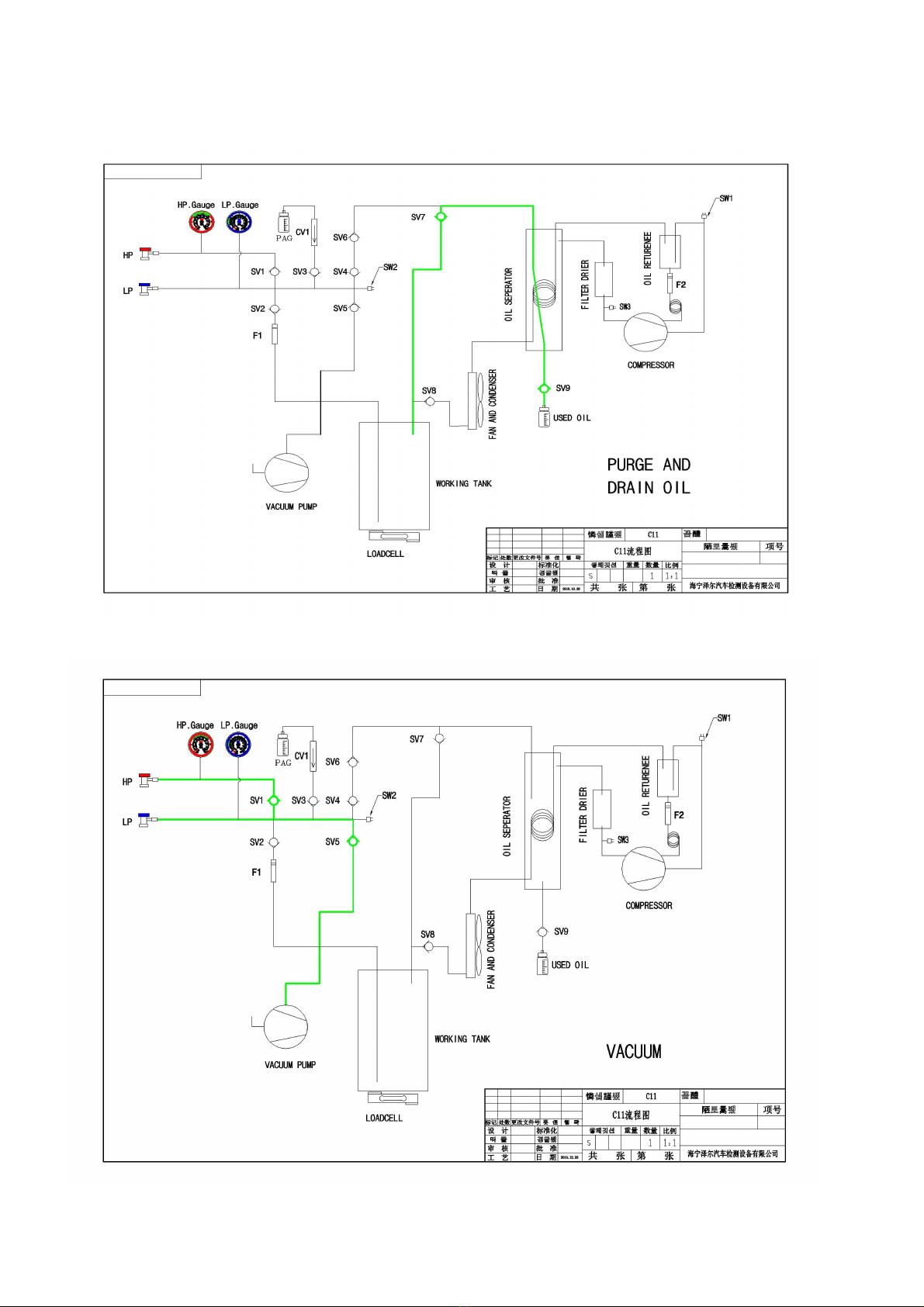

4.4 Purge and drain oil

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Vacuum

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .. . . . . . . . . . .. . . . . . . . .. . ... . . . .

4.6 PA oil injection

. . . . . . . . . . . . . . . . . . . . . . . . . . . ........................... . . . . . . . . . .8

4.7 Recharge

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .. . .. . . . . .8

4.8 Pressure Up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . .. . . . . . . . . .. . . . . . . .9

4.9 Pressure Down

. . . . . . . . . . . . . . . . . . . . . . . . . . . ..... . .. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .. . .. . . .. . . . . . .. . .. . . .. . . . . .10

5.1 Recovery

.....................................................................10

5.2 Vacuum

........................................ . . . ..........................10

5.3 Recharge

................................................. ...................11

5.4 Output check table

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

6 Load cell check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . .. . . . . .. . . . . . . 12

Compressor Suction and Discharge Pressure Test . . . . . . . . . . . . . . . . . .. . .. . . .. . . . . . . . 13

8 Trouble shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .14

8.1 No display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.2 Recovery not start

. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.3 Recovery endless

. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.4 Will Not Evacuate

. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.5 Will not charge

. . . . . . . . . . . ... . . . . ... . . . ... . . . . .. . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.6 Recharge low efficiency

............................................................14

9. Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9.1 Disposing of used fluids

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.2 Disposing of packaging material

...................................................15

9.3 Scrapping old unit

..............................................................15

10. Spare part list.................................................................16