Page 6 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Installation procedure continued

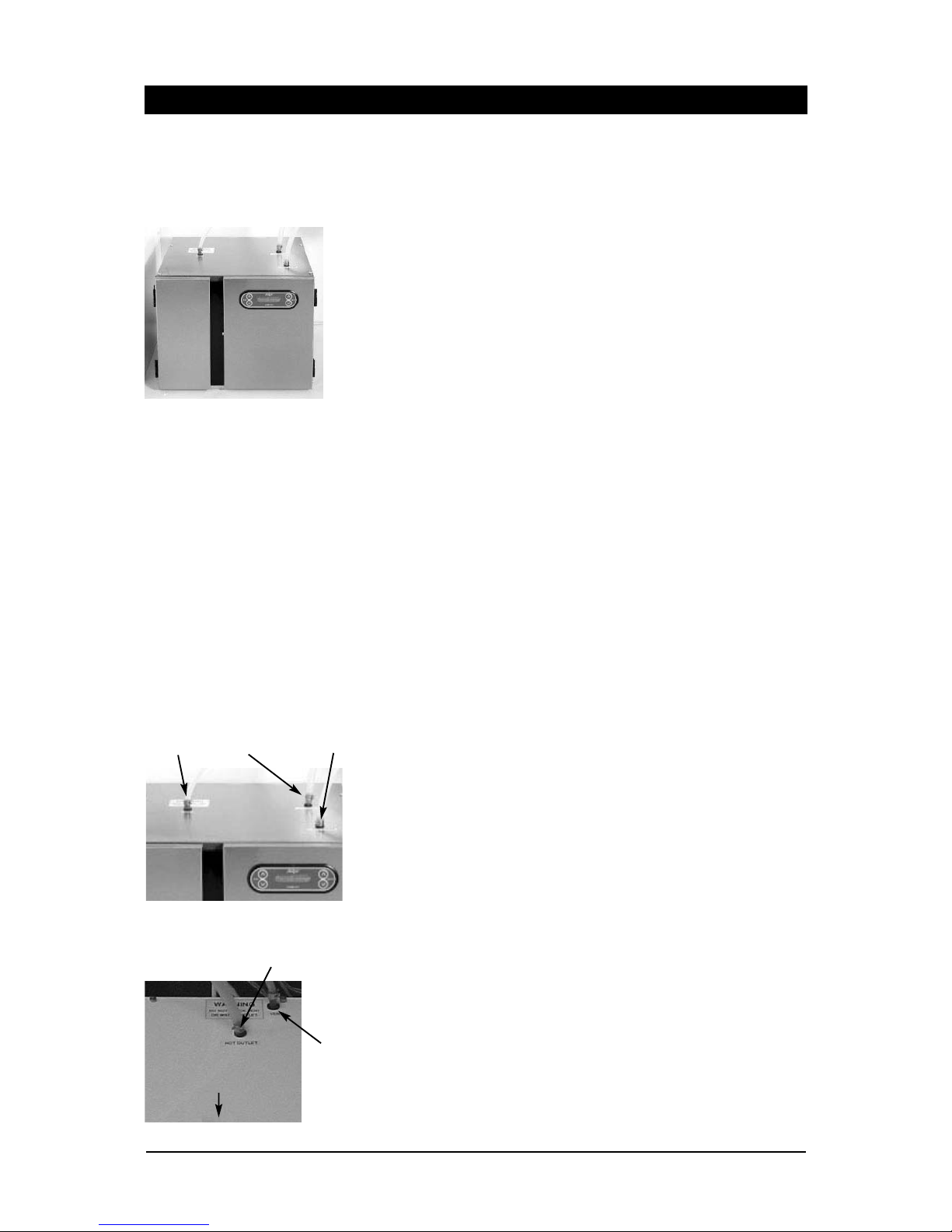

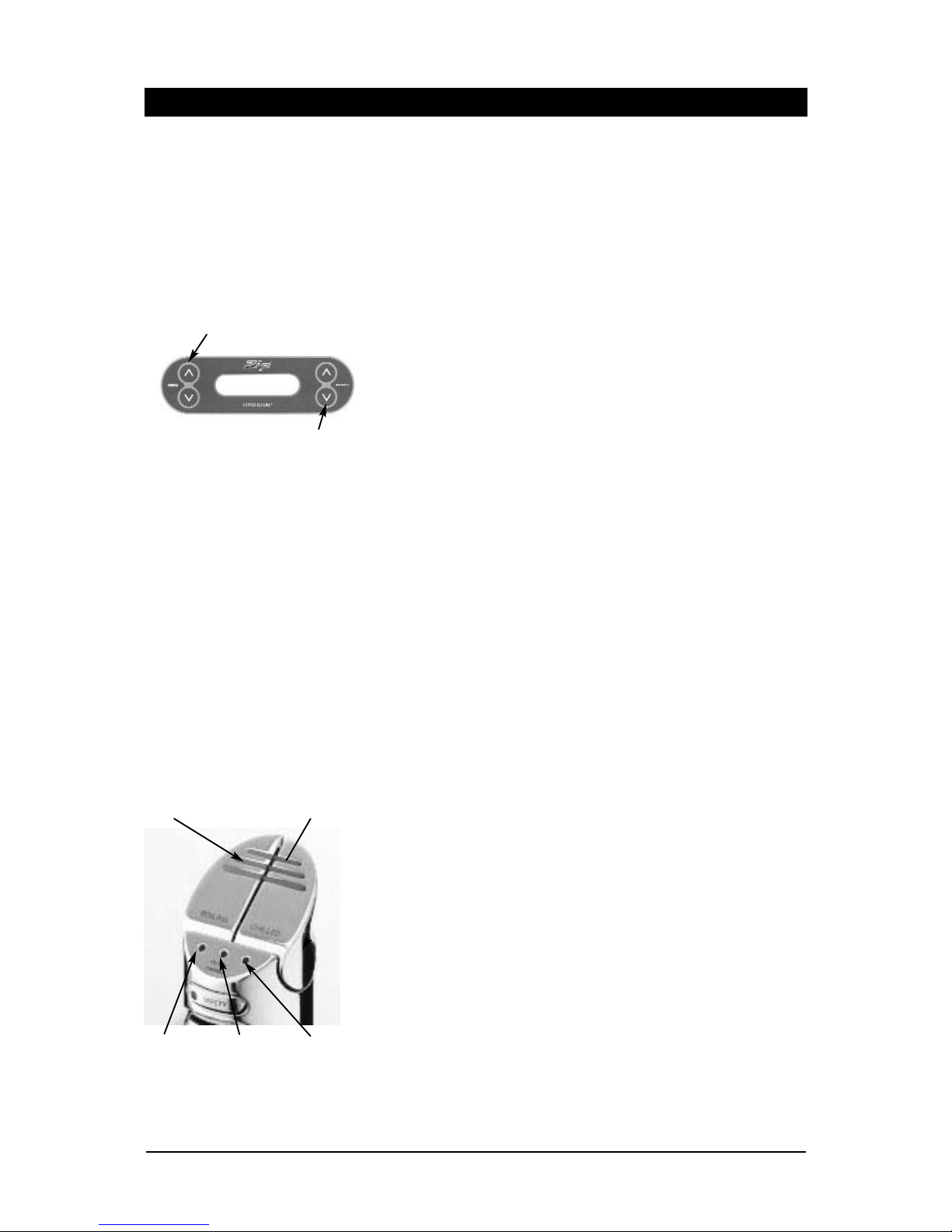

Vent line Chilled lineHot line

Front

Vent

Hot Outlet

Step B - Installing the undersink unit (all models)

SPECIAL NOTE: The HydroTap undersink units are heavy, take note of the

weights listed in the table on page 4. If you think you cannot lift the unit

safely, get help and avoid possible injury.

Before positioning the heater connect the braided water inlet hose (supplied) to the

cold water inlet on the unit.This is located at the rear of the unit.

Position the Zenith HydroTap undersink unit as close as possible to directly beneath

the Zenith HydroTap tap head.

The connection tubes supplied with the tap head assembly CANNOT be lengthened.

Leave at least a 50 mm air-gap without obstruction on each side of the unit.

Adjust both cupboard door hinges and attach the supplied rubber door buffers to

the doors to create a 4 mm air-gap between the doors and the cupboard.This is

the minimum ventilation requirement for low usage installations.

Important Note: Proper air circulation must be provided for all Boiling and Chilled

models.The system will operate correctly only if the recommended air gaps are

achieved during installation.A ventilation hole measuring 100mm must be cut into

the top half of the cupboard door to accommodate the air vent provided. Make

sure that the undersink unit ventilation grilles are not obstructed in any way.

This instruction is critical!

Cupboard ventilation for Boiling only and Boiling Ambient models is recommended

but not essential.

Step C - Connecting the tap

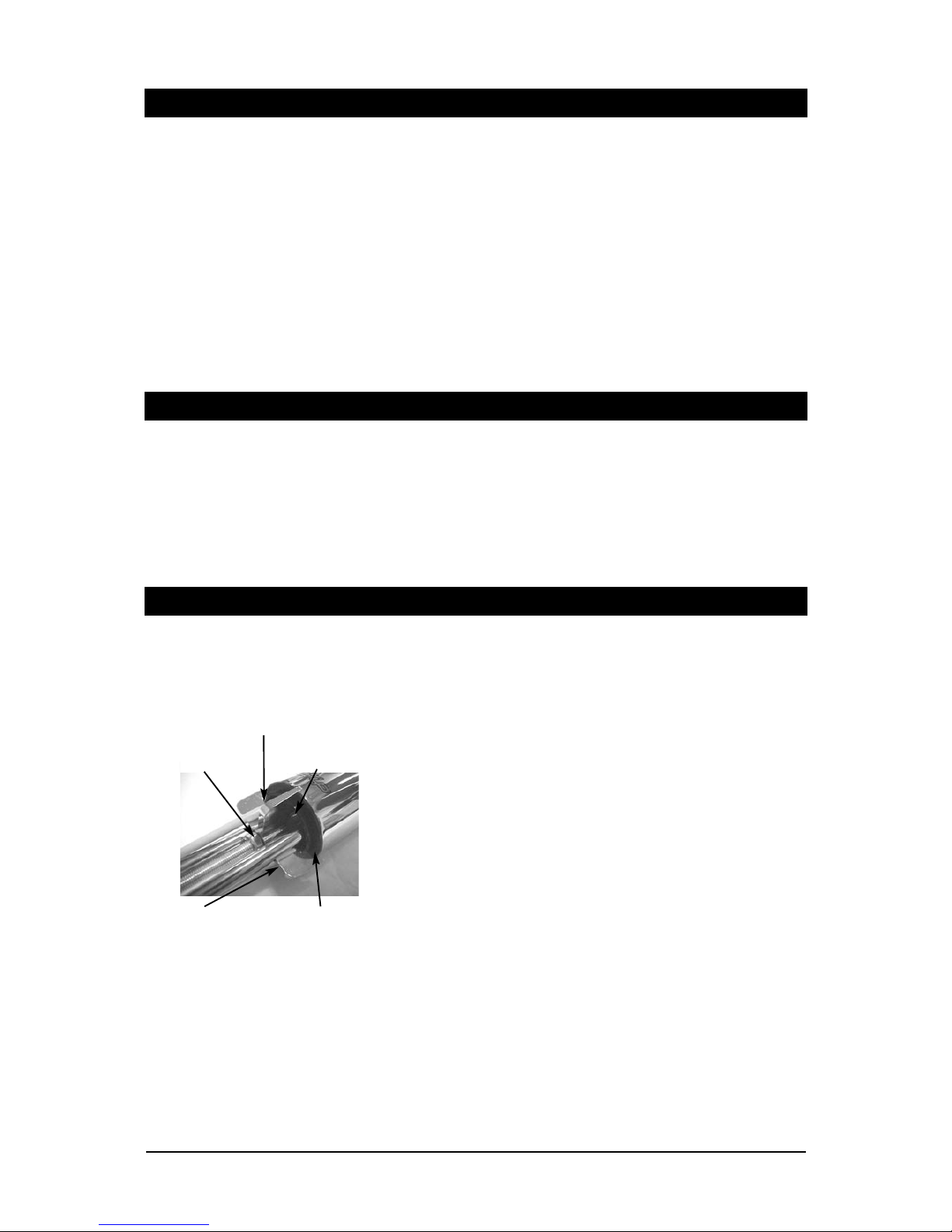

Model BC and HT (boiling/chilled models)

Measure and trim the blue tube and connect it to the chilled water outlet located on

the top front, right hand side of the nder-sink unit. Use spring clamps provided.

Measure and trim the red marked tube and connect it to the hot water outlet

located on the top center,right hand side of the undersink unit. Use spring clamps

provided.

Measure and trim the unmarked tube and connect it to the vent outlet located on

the top center, left hand side the top of the undersink unit.Use spring clamps

provided.

NOTE: All tubes must have a continuous fall back to the undersink unit.

Connect the tap USB connector to the USB connector attached to the undersink

unit. Orient the USB plug carefully and connect, do not force the plug. Once

connected, fix the cable to the wall, ensure it is away from any possible water

splashes and is off the floor.

Note: When trimming any silicon tubes trim to minimum length, do not loop any

excess or allow kinking of the tubes.When connecting, slide the tube over the pipe

at least 25mm.

Model B, BD and HT (boiling only models)

Measure and trim the red marked tube and / or the blue marked tube and connect

it to the hot water outlet and amblient outlet if a BD model, on the top of the

undersink unit. Use spring clamps provided.

Measure and trim the unmarked tube and connect it to the vent outlet on the top of

the undersink unit. Use spring clamps provided.

NOTE: All tubes must have a continuous fall back to the undersink unit.

Connect the tap USB connector to the USB connector attached to the undersink

unit. Orient the USB plug carefully and connect, do not force the plug. Once

connected, fix the cable to the wall, ensure it is away from any possible water

splashes and is off the floor.