1. Safety Precautions ............................3

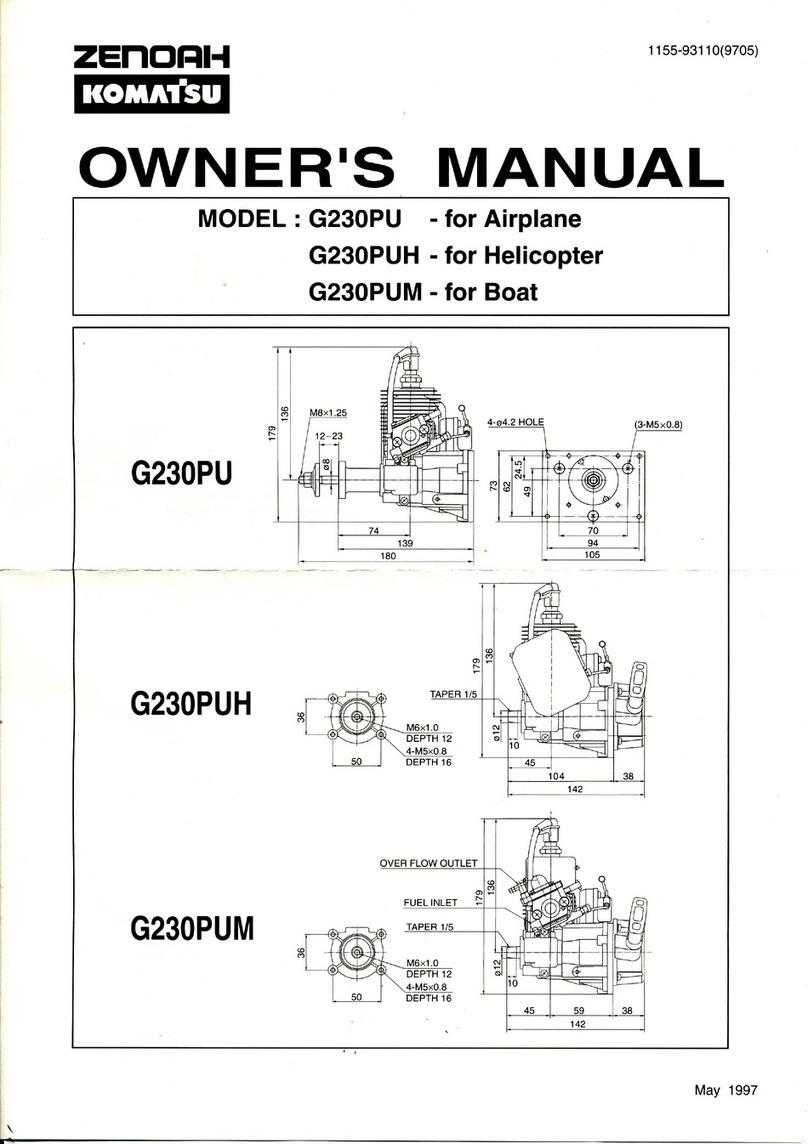

2. Engine Assembling............................4

3. Engine Mounting................................5

4. Screw Propeller .................................6

5. Fuel....................................................7

6. Starting ..............................................8

7. How to Stop The Engine....................8

8. Carburetor Adjustment ......................9

9. Engine Break-In.................................11

10. Operation...........................................11

11.

Maintenance......................................12

12. Special Tools.....................................17

13. Trouble Shooting ...............................18

14. Parts List............................................20

15. Warranty.............................................23

Contents

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING AVERTISSEMENT ADVERTENCIA

Los gases de escape del motor de

este producto contienen

sustancias químicas conocidas

por el Estado de California como

causantes de cáncer,

malformaciones en recién nacidos

y otros problemas de

reproducción.

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.

The engine exhaust from this

product contains chemicals

known to the State of California to

cause cancer, birth defects or

other reproductive harm.

WARNING AVERTISSEMENT ADVERTENCIA

Los gases de escape del motor de

este producto contienen

sustancias químicas conocidas

por el Estado de California como

causantes de cáncer,

malformaciones en recién nacidos

y otros problemas de

reproducción.

Les échappements du moteur de

ce produit contiennent des

produits chimiques connus par

l’Etat de Californie comme étant

responsables de cancers,

d’anomalies congénitales et

d’autres atteintes à l’appareil

reproducteur.