1. SAFETY PRECAUTIONS

. This manua! describes the engine. For its mounting and

control, see the instruction manual for the model

airplane, helicopter and boat.

. Each engine is designed for use on each model

airplane, helicopter and boat. !f it is used for any other

purpose, we cannot be responsible for its reliability or

safety.

. Use genuine parts for replacement.

. Check the propeller, rotor and screw propeller every

time. lf it is damaged, replace it with a new one.

. lf the propeller (or the rotor or the screw propeller) hit

something while the engine is in operation, immediately

stop the engine and check it.

. Start the engine on a flat surface without pebble stones.

. Never modify the flywheel.

. Check the flywheel. lf it is damaged, replace it with a

new one.

. When mixing the fuel, or operating the engine, carry it

out in a well-ventilated place.

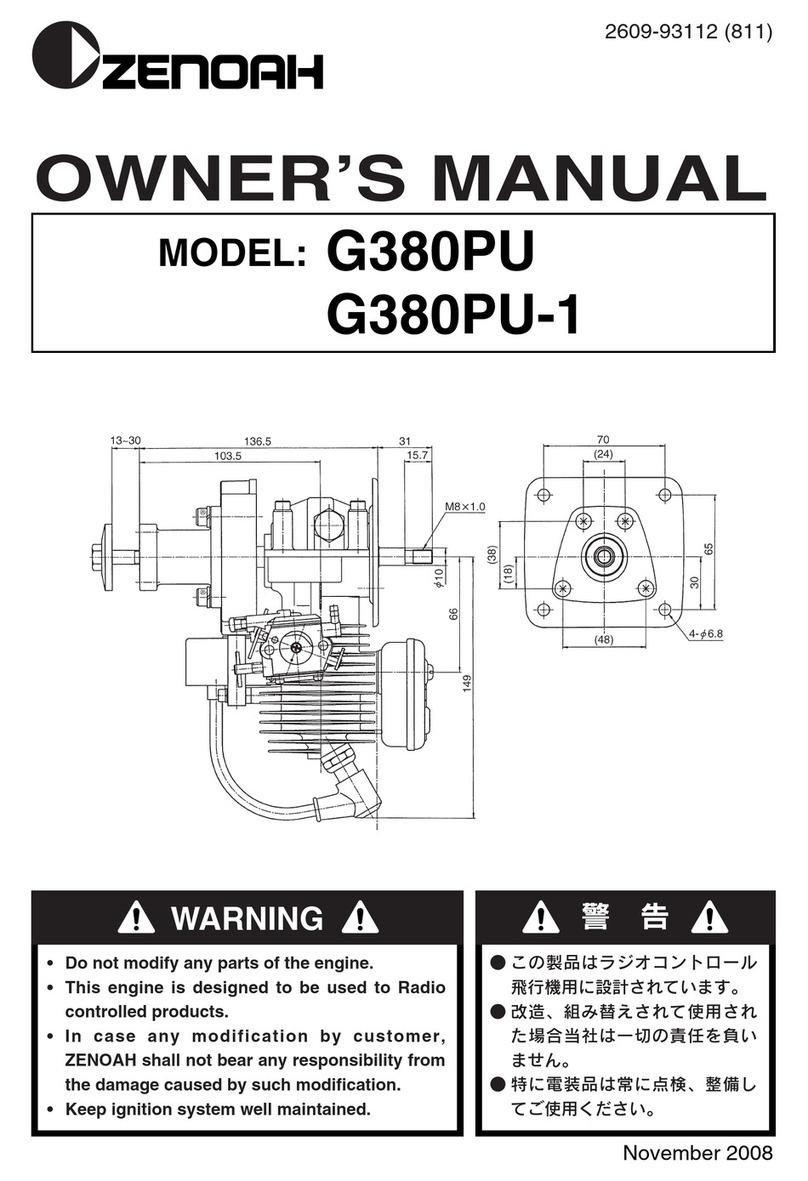

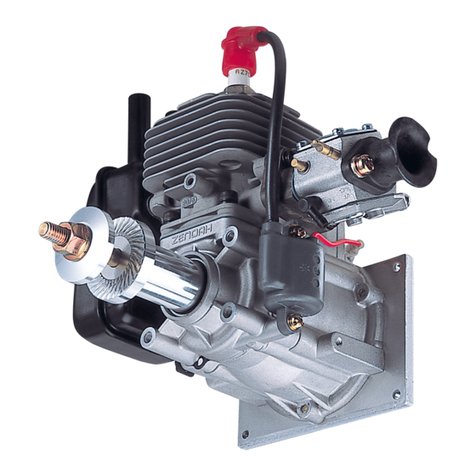

2. MOUNTING G23OPU

Make sure that the G230PU is mounted on the aircraft grade

plywood with more than 6mm of thickness or a mount of

equivalent strength and is firmly fixed with 4 bolts.

I NOTE ]

1. Be sure to set flat washers or metal plate on the reverse

side of the mount to prevent bolts from sinking into the

mount. Before be sure to check for loose bolts.

2. Since the engine is equipped with a float-less carburetor

with a diaphragm pump, the direction of cylinder and

position of fuel tank can be freely selected .

3. lf the rubber joint is placed between the engine and the

body for anti-vibration, check if the rubber is too week and

select the proper hardness of the rubber, in order to avoid

the unexpected vibration under operating engine RPM

zone.

Note carefully that if the engine is vibrated at idling, then

the idling RPM is likely to get unstable due to overflow at

carburetor by the vibration.

4. Coat the bolts for muffler with anti-looser (e.9., Locktite or

equivalent).when assembling.

3. PROPELLER, ROTOR & SCREW PROPELLER

l. Propeller for airplane

The recommended prop sizes are as shown in the table bellow.

DiameterxPitch(in.)

18x6, 16x8- 10

This engine with a standard muffler produces the maximum

output when the engine is running at about 10,000rpm. Be

sure to use a propeller which makes the engine speed

approximately 7,000-9,500rpm while the airplane is flying.

I NOrE ]

When mounting the spinner, set a pin on the hub with more

than 3mm of diameter, thus preventing slipping.

2. Rotor for helicopter

Adjust the rotor-pitch to obtain 9,000-10,000 rpm of the

engine at full throttle operation.

3. Screw Propeller for boat

The exhaust system (e.9., muffler) is not equipped with as

standard. When you select the exhaust system for the

engine, check how many the engine speed (rpm) is

required when the maximum output is generated by using

I"iTJl"l#1"'?,l""loo,ooriatethescrewpropererthat

would meet such engine speed (rpm) that the muftler

required.

In general, standard size of the screw propeller (Surface

prop type) are as follows:

Diameter ( mm )

65-75 Pich ratio ( mm )

1.9 - 1.4

4. FUEL

Mix gasoline and 2-stroke oil at a mixing ratio ol 25 - 40 :1 .

I NOTE ] 1. Be sure to use a gasoline-resistant fuel piping. (Do not use any silicon rubber tube).

2. Never use any alcohol fuel or alcohol added fuel, or the rubber part in the carburetor will be damaged.

5. OPERATION

Hand llip start

Since the G230PU is equipped with the ultra compact C.D.l.

type flywheel magneto ignition system, it should be started

according to the following procedure;

* The magneto system of G230PU is designed in such a way

that when the exhaust port is closed by the piston, that is,

when the compression stroke starts (Refer to Fig. l-A),

sparks are never produced on spark plug no matter how

fast the propeller may be flipped. Be sure to quickly flip the

propeller when the edge of magnet on the rotor is

approaching the coil (Fig. 1-B). lt means that the propeller

should be quickly flipped about 90 degrees in crank angle

before the compression is about to start.

How to Start the Engine

1. For Airplane

a. Fill the fuel tank with the fuel .

b. Choke the engine and turn the propeller a few tinieS until

the fuel appears at the carburetor.

c. Set the throttle valve at the idle position or at the position

@il

Fig.1-A Fig.1-B

slightly open from the idle position. Quickly flip the

propeller in the counterclockwise direction according to

the procedure described above. Flip the propeller a few

times. Then the engine starts.

2. For Helicopter & Boat

a. Fill the fuel tank with the fuel.

b. Push the priming bulb upper the carburetor until fuel

appears in the priming bulb.(for Helicopter)

c. Choke the engine and open the throttle valve

approximately 113-112 of the full open position.