zero

HOME AUTOMATION Z03 - SWING GATE

PG8

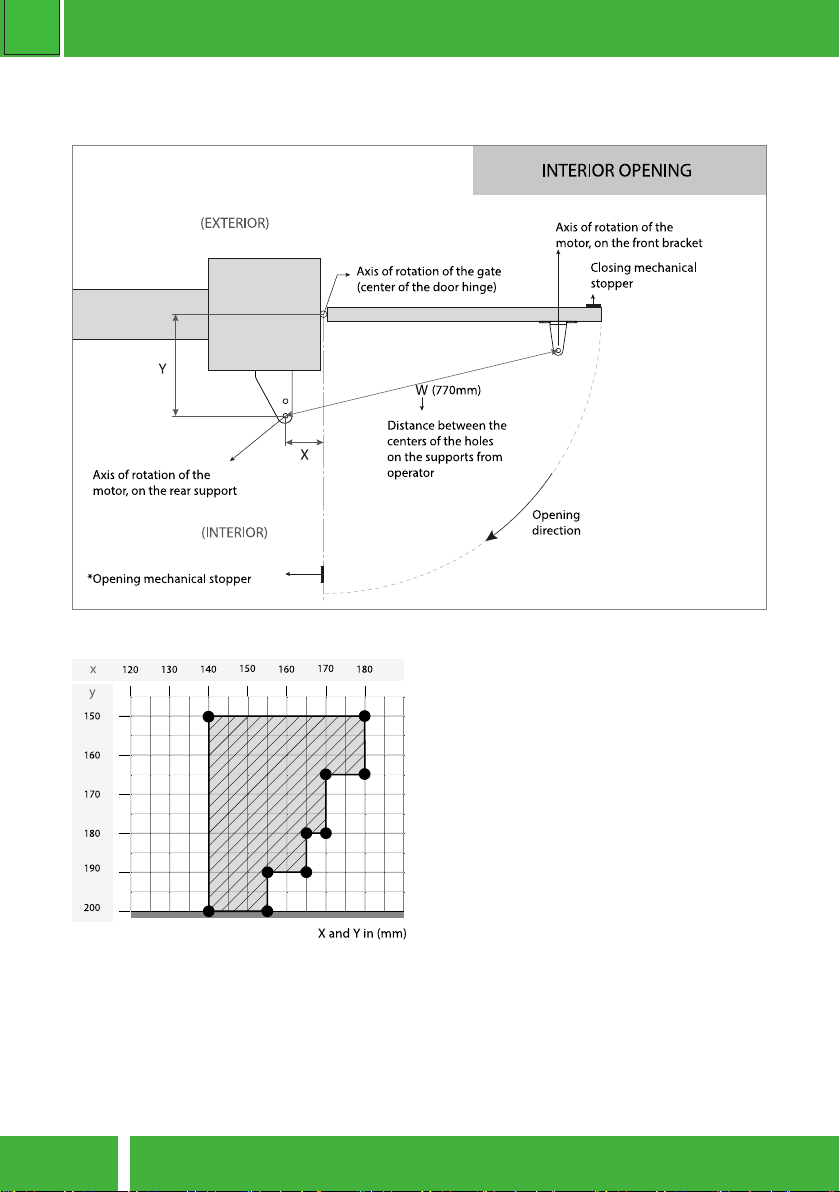

01. Fix the supports.

The rear support must be xed on the pillar

or wall. The front support must be xed on

the gate. Respect the height and distance

measures between the front and rear sup-

ports. It can be xed by using screws with

mechanical bushing or chemical welding

process, because both provide an appro-

priate support

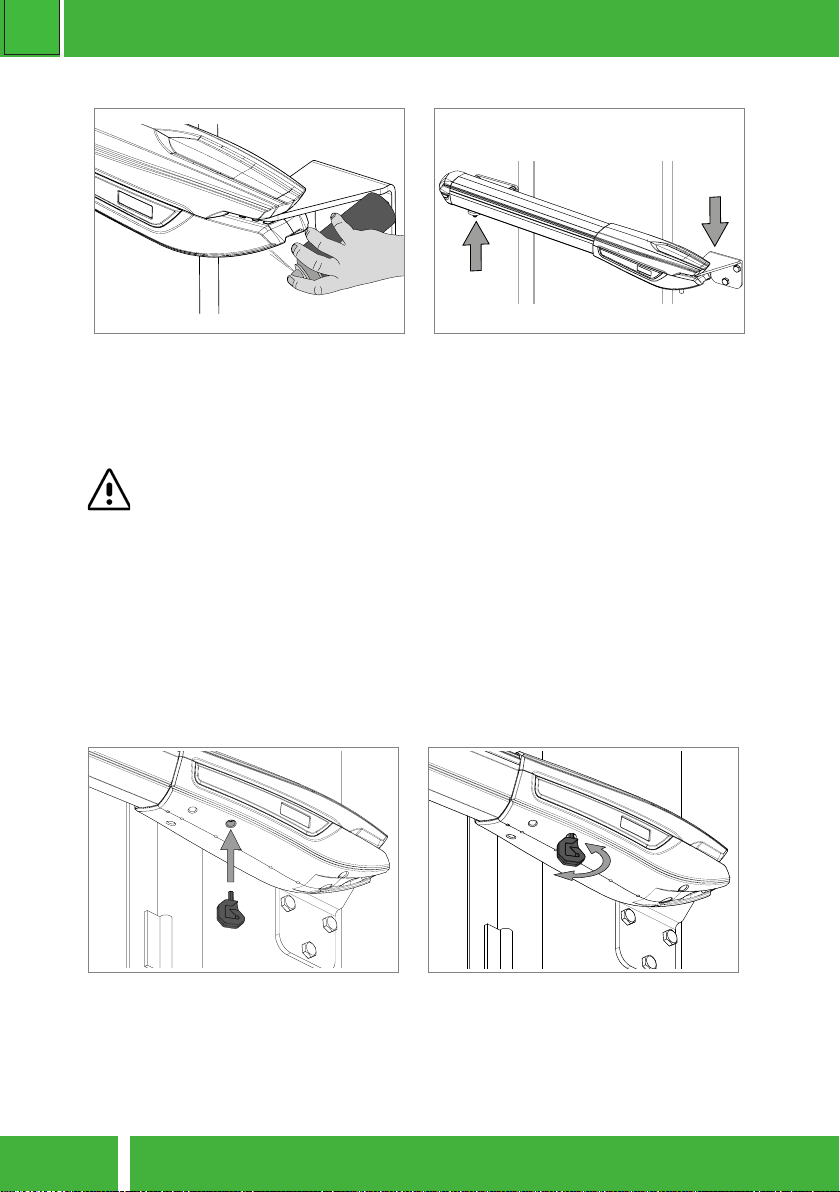

02. Install the operator on the supports

The operator must be placed on both sup-

ports the same me to avoid leaving the

operator suspended by only one of the

supports. To make the task easier, you

should unlock the operator in order to be

able to stretch/retract arm easily,to get the

correct posion for supports.

03. Install the pins removed earlier on each

side with a small amount of lubricant for

lessfricon. Unlock the motor and move

the door manually to see if the door opens

and closes uniformly and correctly, wi-

thout any irregular fricon during its enre

movement. This will ensure that the motor

is not subjected to problems during ope-

raon.

04. Connecng operator to control board

and conguring control devices. With the

operator installed, connect it to control

board for system conguraon (see con-

trol board user manual). Must also con-

gure the desired control devices (transmit-

ters, wall switch, etc.) and other addional

components such as antenna, warning

light, key selector, among others.

It is important to respect this installaon order!

Otherwise, it is not possible to ensure correct installaon and operators may not

work properly!

INSTALLATION STEPS