If the problem cannot be solved, please do not hesitate to contact usin a timely manner.

7. Notes

There are laser and detecting sensor inside, please do not put the sensor under direct light,

otherwise the sensor will be in disorder, and even the sensor will be damaged.

The light key changes as the temperature changes, so please please do not place it under direct

sun.

The light pulse emitted by the device may damage your eyes. Please do not look into the light

source at any time to avoid damage!

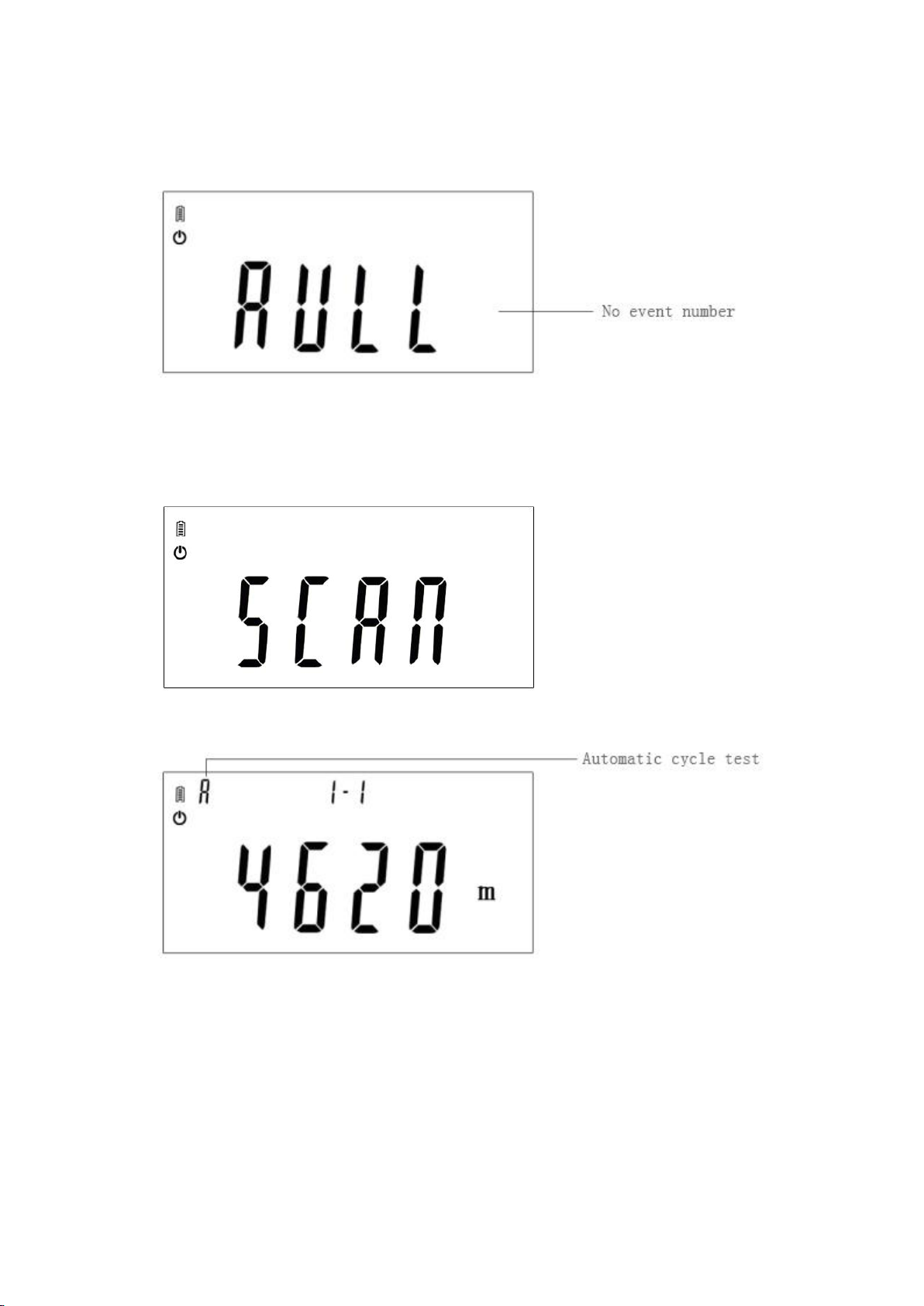

Before “SCAN”, please make sure that the optical fiber and port are connected firstly. Please do

not pull and insert optical fiber in the process of “SCAN” to avoid device damage because of

reflection.

8、

We suggest that please do not repair by yourself.

Our company give our promise tothe material and process of the products, warrantyperiodis

18months starting from the day when the products were received.If problems are found in

respect to the quality of our products that are still within the warranty period, our company will

perform correspondent management or will switch the product. But under all circumstance, the

responsibility will not surpass the purchase value of the product.

If there are any problems with the use of the instrument that cannot be resolved with

commonfaults and troubleshooting advice, users should not open the device’s case on their own,

but rather to contact our company.

As to the malfunction made by the disadvantage of the product, our company will be in

charge of repairing or changing product for free.

These following problems/faults are not included in warranty: 1. Repair or modify without

authorization; 2. inappropriate or negligent usage and accident, etc.