INSTALLATION AND OPERATING INSTRUCTIONS: Cutting tongs, pneumatic, ZK1000 series

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau ● Germany ●+49 7844 9138 0 ● +49 7844 9138 80 ● www.zimmer-group.com

Installation and

operating instructions

ZK1000 series

DDOC01013

Index a

EN/2022-19-07

Im Salmenkopf 5

77866 Rheinau

Germany

+49 7844 9138 0

+49 7844 9138 80

www.zimmer-group.com

1. Supporting documents

NOTICE

Read through the installation and operating instructions carefully before installing the product!

The installation and operating instructions contain important notes for your personal safety. They must be read and

understood by all persons who work with or handle the product during any phase of the product lifetime.

The documents listed below are available for download on our website (www.zimmer-group.com).

Only those documents currently available on the website are valid.

• Catalogs, drawings, CAD data, performance data

• Information on accessories

• Detailed installation and operating instructions

• Technical data sheets

• General Terms and Conditions of Business with specications for the warranty entitlement

2. Safety notices

CAUTION

Risk of injury and material damage in case of non-compliance

Installation, commissioning, maintenance and repairs may only be performed by qualied specialists in accordance

with these installation and operating instructions.

The product is state-of-the-art. It is mounted to industrial machines and is used to hold tools.

The product can only become a source of hazard if, for example:

• The product is not properly installed, used or maintained.

• The product is not used for its designated purpose.

• The locally applicable regulations, laws, directives or guidelines are not observed.

The product may only be used in accordance with its intended use and technical data. Zimmer GmbH shall accept

no liability for any damage caused by improper use.

Any use other than the intended use requires written approval from Zimmer GmbH.

Make sure that the power supply is disconnected before you install, retool or service the product.

Zimmer GmbH recommends performing maintenance tasks, renovation work or attachment work outside of the

machine's danger zone when possible.

When commissioning or testing, make sure that the product cannot be actuated by mistake.

Modications to the product, such as adding drilled holes or threads, may be made only with prior approval from

Zimmer GmbH.

The specied maintenance intervals are to be observed; also refer to the "Maintenance" section. When the product is

used under extreme conditions, the maintenance interval must be adapted.

Use of the product under extreme conditions, such as aggressive liquids and abrasive dusts, is subject to prior

approval from Zimmer GmbH.

Do not reach into the operational range of the product!

3. Proper use

NOTICE

The product is only to be used in its original state with its original accessories, with no unauthorized changes and

within the scope of its dened parameters for use.

Zimmer GmbH shall accept no liability for any damage caused by improper use.

The product is designed exclusively for pneumatic operation.

The product is designated for use in enclosed rooms for separating dened materials.

Direct contact with perishable goods/food is not permitted.

It is not suited for operation with other media such as liquids or gases.

4. Personnel qualication

Installation, commissioning and maintenance may only be performed by qualied personnel. These persons must have read and

understood the installation and operating instructions in full.

5. Product description

5.1 Forces and torques

INFORMATION

For information on forces and torques, please visit our website.

Zimmer Customer Service is available to provide you with assistance if you have any further questions.

5.2 Type plate

A type plate is attached to the housing of the product.

The conrmation number and the article number are indicated on this type plate.

The conrmation number should be assigned to the project.

• Article number: am

• Conrmation number: an

INFORMATION

Please state the conrmation number in the event of damage or a complaint.

Zimmer Customer Service is available to provide you with assistance if you have any further questions.

6. Function

The function is based on a single-acting vented pneumatic piston with spring return. As a result of its structure, the ZK1000

series product reduces interference contours, thereby enabling simple integration into the machine design.

The ZK1000 series makes it possible to use different cutting geometries and materials.

The ZK1000 series has an integrated magnetic eld sensor. This ensures process reliability for sensing the positions and

transmitting them to the control system.

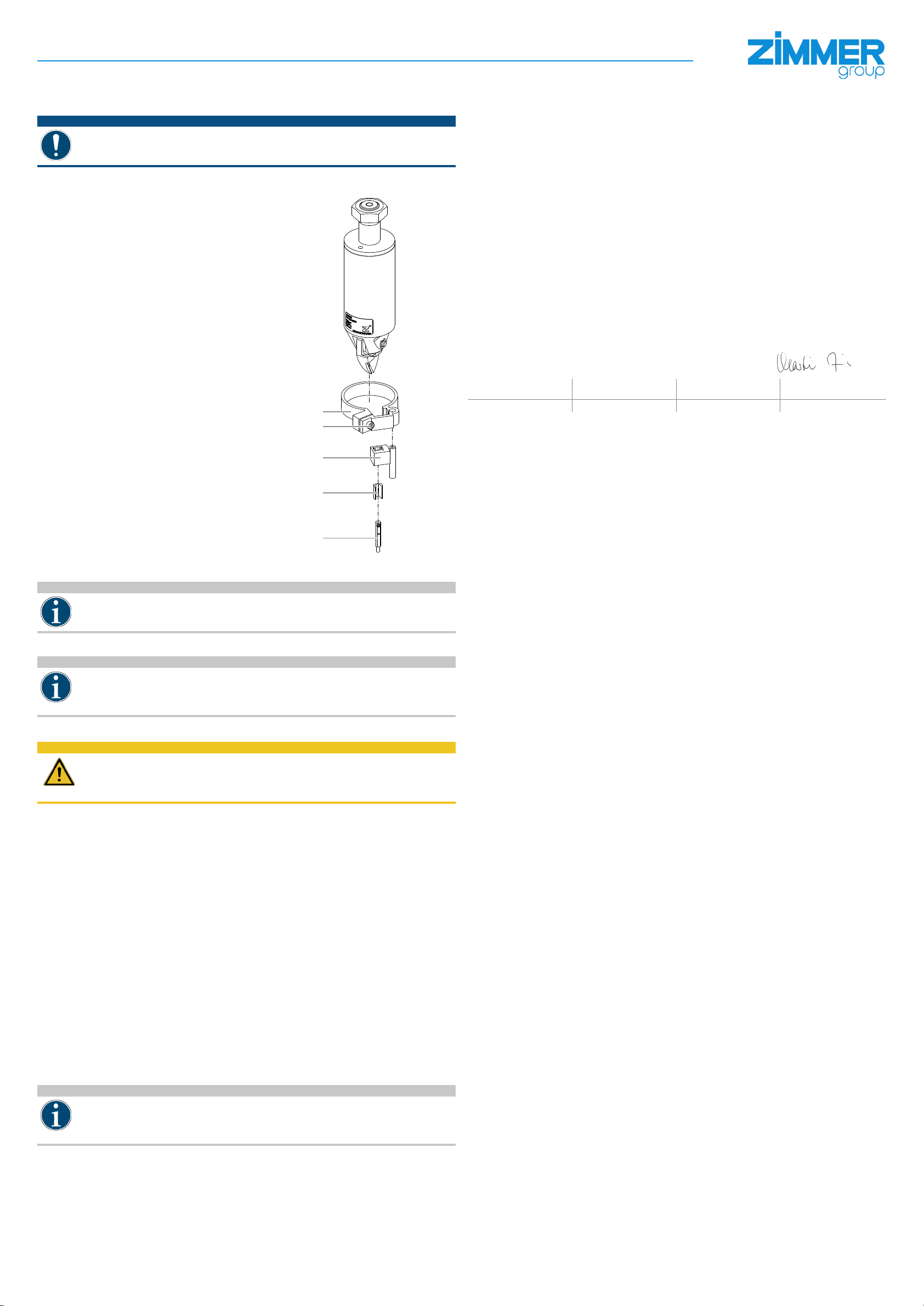

1Power supply ZK1000 product series

2

3

2Mounting and positioning

3Cutting insert

4Mounting clamp for magnetic eld sensor

5Magnetic eld sensor

6Housing

7. Installation

7.1 General installation information

WARNING

Risk of injury in case of unexpected movement of the machine or system into which the product is to be installed.

►Switch off the power supply to the machine before all work.

►Secure the machine against being switched on unintentionally.

►Check the machine for any residual energy.

CAUTION

Risk of injury in the event of unexpected movement of the product when the power supply is connected.

►Switch off the power supply to the product before all work.

►Secure the power supply against being switched on unintentionally.

►Check the power supply for any residual energy.

NOTICE

Switch off the power supply before any assembly, installation or maintenance work.

The product must be installed on a suitable mounting surface in accordance with the atness specications.

ÖPermissible atness imperfection: 0.03 mm

ÖThe locknut is included in the scope of delivery.

ÖStrength class of the locknut at least 8.8 DIN EN ISO 4762

ÖObserve the tightening torque of the locknut.

ÖZimmer GmbH recommends verifying the permitted load-carrying capacity of the required screw connections in accordance

with VDI 2230.

ÖMake sure the mounting surface is suciently rigid and at.

ÖThe exact positions can be found on the technical data sheet on our website www.zimmer-group.com.

7.2 Installing mechanic

The gripper can be installed on the mounting piece using the

screw thread 2and the locknutbl.

The following work steps must be observed during installation:

►Guide the product into the borehole on the mounting piece.

ÖIt is held using the mating part bp.

►Secure the product using the locknut bl.

ÖAttach the locknut blso that it is hand-tight.

►Align the product.

►Tighten the locknut blto the specied tightening torque. 2

bl

9

bp

7.3 Installing the power supply

Insert the screw connection 9into the designated connection.

NOTICE

Close off unused pneumatic connections with dummy plugs.

The authorized pneumatic connections that are available can be found in the accessories list, which is available on

our website.

The necessary ordering information can also be found there.

ÖUse compressed air in accordance with DIN ISO 8573-1 [4:4:4].

7.4 Installing/disassembling the cutting insert

7.4.1 Installation

The following work steps must be observed when installing the

cutting insert:

►Switch off the power supply to the product.

►Check the power supply for any residual energy.

►Guide the cutting insert bninto the housing 6.

►Secure the cutting insert bnusing the bearing pin bo.

►Secure the bearing pin bousing the lock washers bm.

7.4.2 Uninstallation

The following work steps must be observed when disassembling

the cutting insert:

►Switch off the power supply to the product.

►Check the power supply for any residual energy.

►Remove the lock washers bm.

►Pull out the bearing pin bo.

ÖIn doing so, hold the cutting insert bnsecurely.

►Take the cutting insert bnout of the housing 6.

bo