oThe goal is to mount each panel level and plumb.

oBegin by mou g your first half of each Z clip to the back of the first panel. Orient

the clip to be facing downward (open gap is down). Install the uppermost clip no

closer than 1” to the horizontal top edge of the panel. Clips should d to

be:

§Parallel to the horizontal edge of the panel.

§Centered on the panel and no closer than 6” away from each vertical side

edge.

§Separate each clip to be p ned no closer than 2’ below the clip above it.

och the panel clip halves to the panel using pan head #8 sheet metal screws, ½”

long. You will need to drill holes for these screws in the Z clip halves, but not into the

panel itself. Do n any screw anchor to be no less

than every 12” along the clip.

oWith each half clip now a d to the panels, you can coordinate the placement of

the opposing half of each clip a ed to the substrate. BE SURE YOUR PLACEMENTS

ARE DESIGNED TO ALLOW FOR THE DROP IN HEIGHT ALLOWANCE NEEDED TO LIFT

THE PANEL OVER THE BOTTOM CLIPS BEFORE SEATING EACH.

oMeasure down from the ceiling on the substrate uppermost clip on

a horizontal line which is placed to allow the two halves to be seated properly once

the panel is installed. Verify that these re level and properly spaced to

coordinate with the opposing halves before commi ng.

oInstall these clips using a suitable anchor for your substrate. Most commonly, that

will be 5/8” gyp board. Select your anchor knowing that the best choice for the screw

is a pan or truss head #8 of appropriate length to securely embed into the wall studs.

We do not recommend the use of fluted head drywall screws for this. You will need

to drill holes for these screws in each of the Z clip halves.

oWith the wall halves now secured e panel to slip over the wall Z clips

and then drop into properly seated

Using Stand-Offs

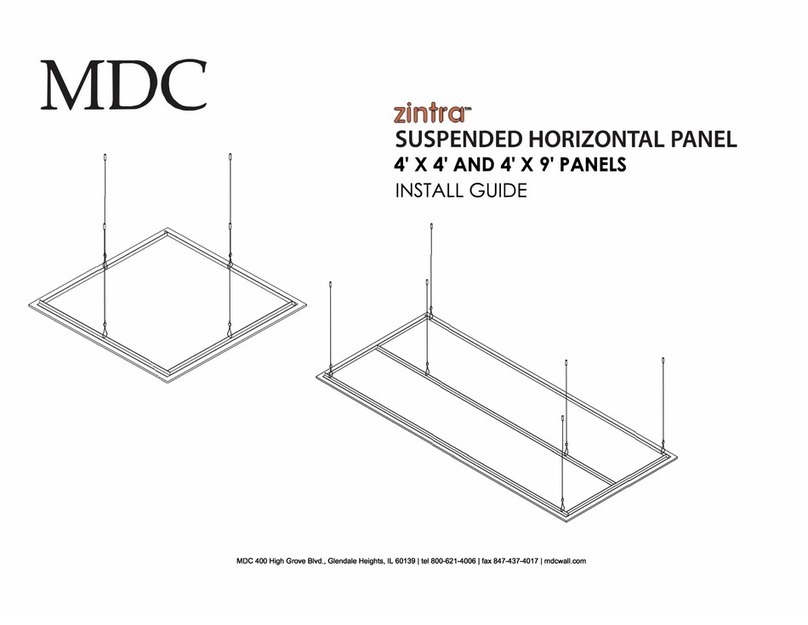

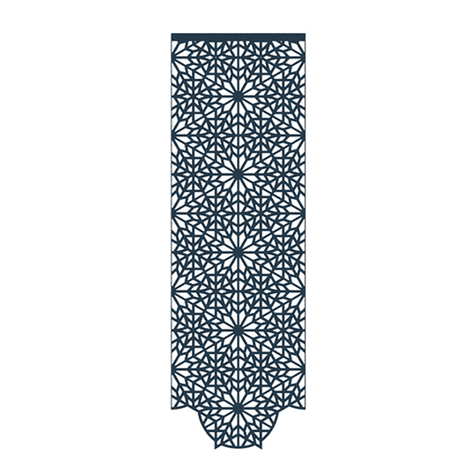

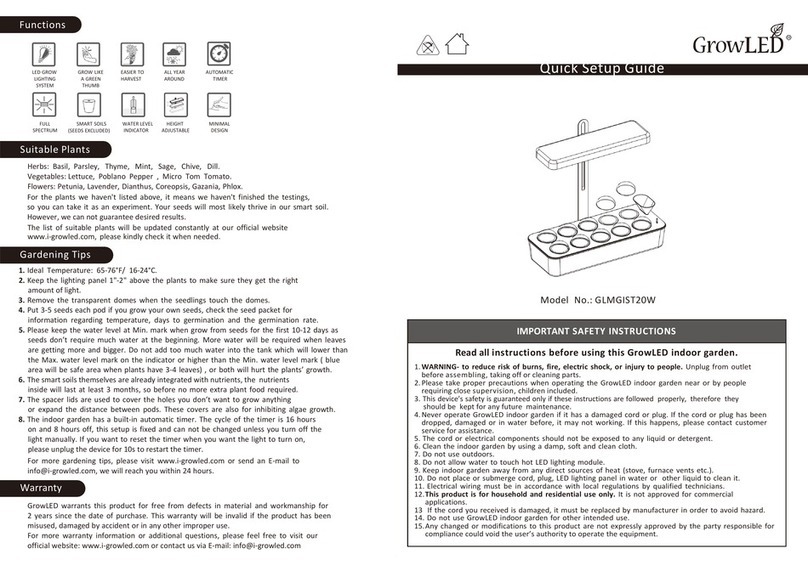

oThe number of stand offs will be determined by your panel dimensions. Please refer

to the following diagram for an overview of how many that might be. Blocking is

also recommended with Stand-Offs as a hidden support to prevent caving of panels.

Stand-off placement guide - Stand-offs should be 3” from the ed ge of panel

2’ x 2’ 2’ x 4’ 2’ x 9’ 4’ x 4’ 4’ x 9’

Toll free 1.800.268.1300 Sans frais 1.800.361.7881

TORONTO 88 Ronson Drive, Etobicoke, Ontario M9W 1B9

MONTREAL 4269 Ste. Catherine Ouest #701 Montreal, Quebec H3Z 1P7

VANCOUVER 611 Alexander Street, Suite 303 Vancouver, British Columbia V6A 1E1