Let’s get started.

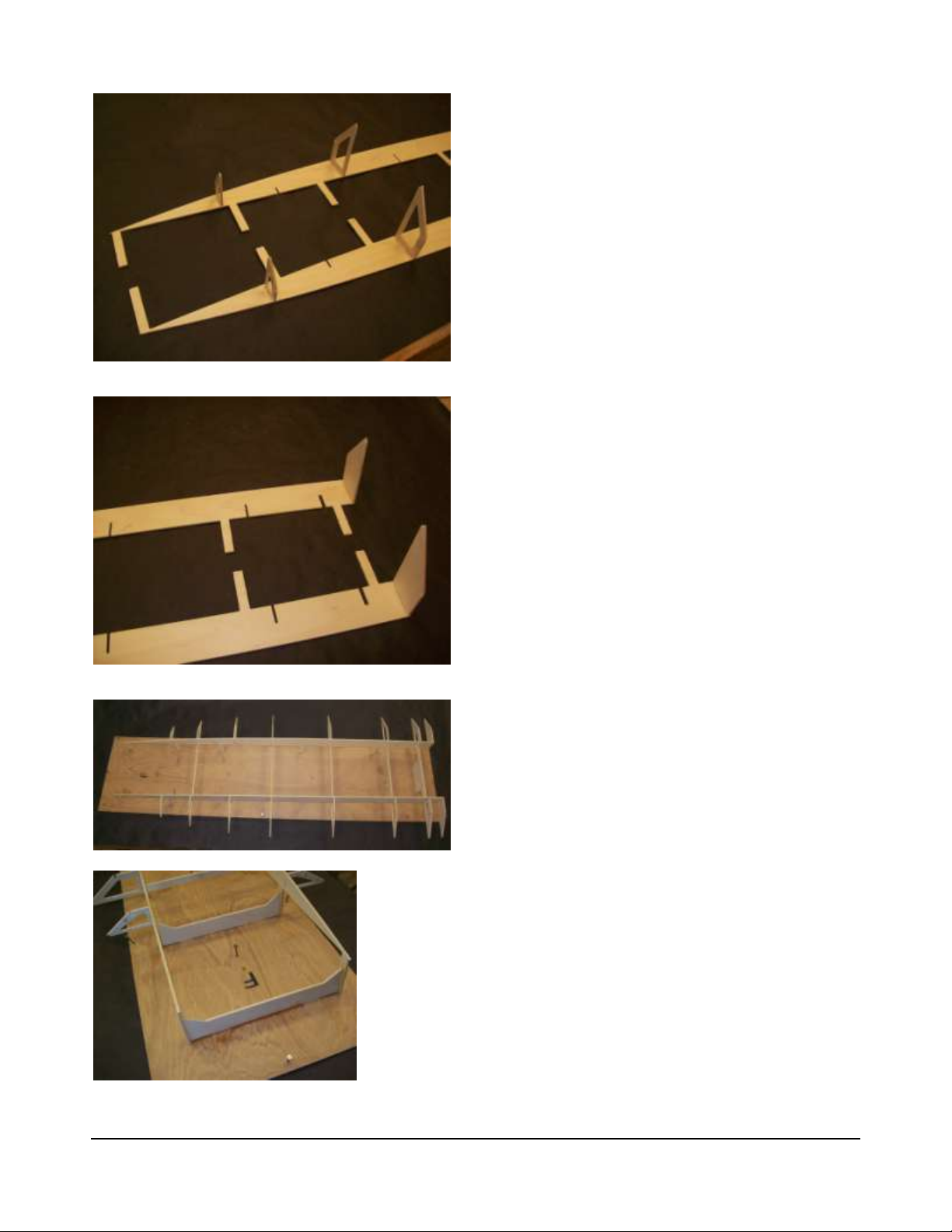

Attach the jig board to your FLAT bench (or 12x48

ply) with screws, nails, clamps or whatever you

need, to make sure it’s attached to the surface.

Make sure the “F” is so that you can read it.

Remove bulkheads R, 4, 6 and the (2) sponson

sides.

Sand the edges with 80 grit to remove the fuzz, as

well as the little tabs that held them in the sheet.

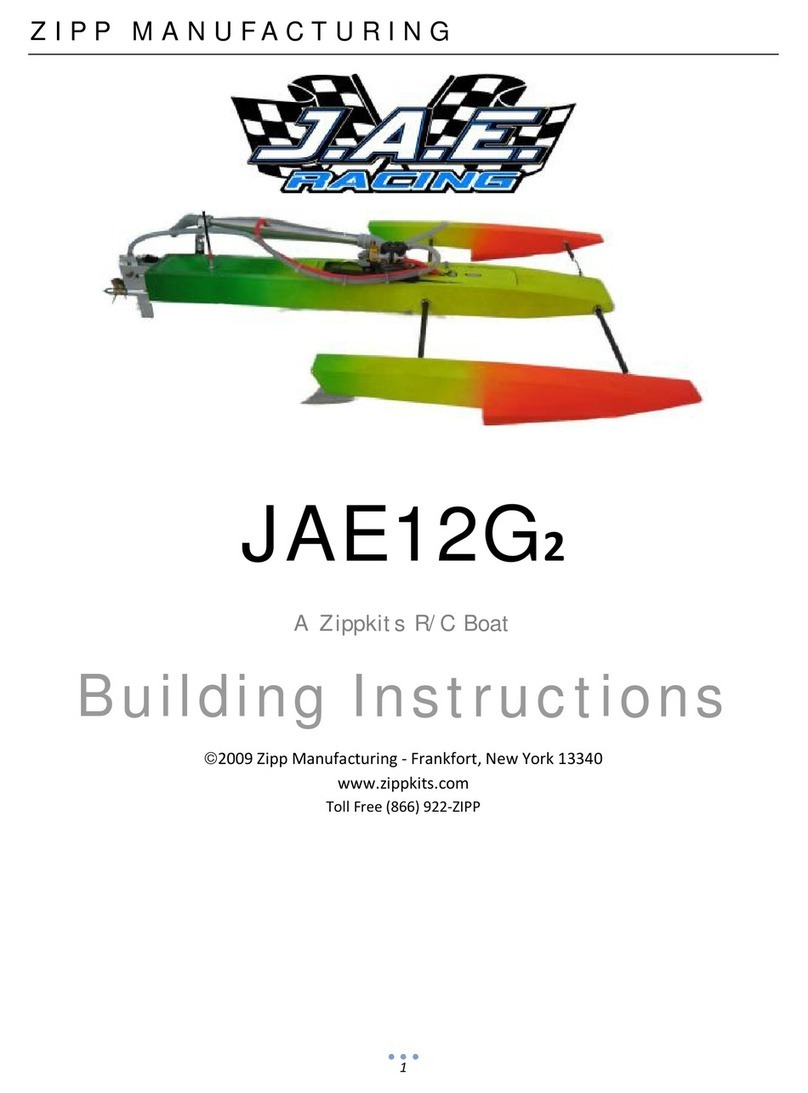

Lay each sponson side on your bench so that they

are mirror images of each other.

Test fit the half bulkheads R, 4 and 6 into the sides.

Be sure that you understand which is the bottom of

the sponson sides and bulkheads. Put pieces of

waxed paper under the areas you are gluing so that

you don’t attach the parts to the bench.

If all is well, glue the half bulkheads in place with

medium CA and accelerator.

Use a square to be sure that all bulkheads are 90

degrees to the side.

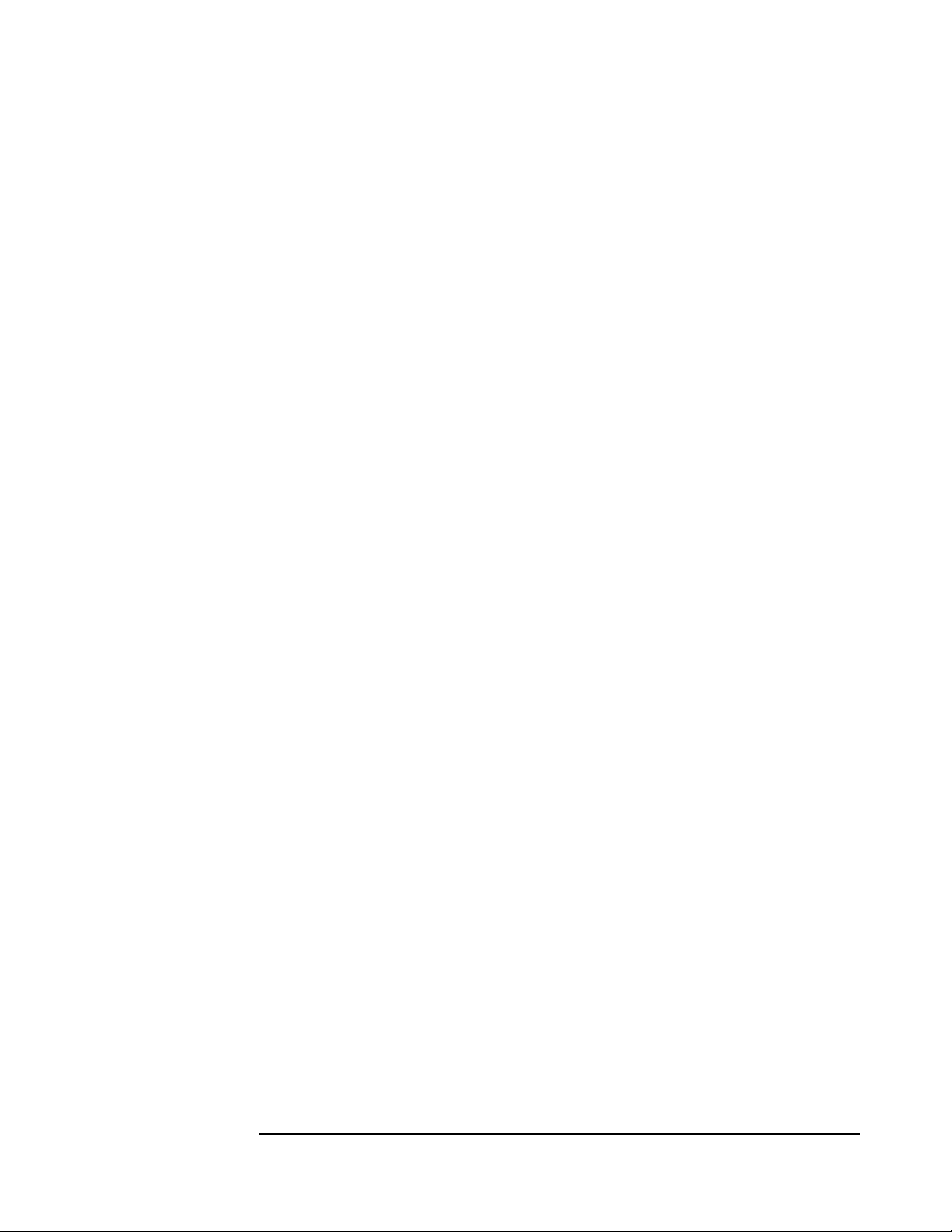

Remove all remaining bulkheads from their sheets,

and sand the edges smooth as before. Make sure

all parts are marked before you remove them.

Assemble the bulkheads into the slots in the sides,

including the ¼ inch transom bulkhead. Be sure that

all are in the correct slot. Don’t glue anything yet.

Put this whole contraption on the jig, and carefully

insert each tab into its jig slot.

You can use a small hammer to tap each bulkhead

to be sure it is seated.

Don’t let the tabs extend below the jig, but make

sure that all tabs are fully inserted.

Once you are happy with the way everything goes

together, start gluing the tabs into the jig.

Tap each tab to be sure it is fully seated.

Remove and sand the jig supports, and glue them

to the jig at bulkheads 6 and the nose. The

supports glue into slots in the jig.

Using thin CA and accelerator, glue the bulkheads

to the sponson insides. Don’t glue the ¼ inch

transom yet. Be sure that all bulkheads are flush

top and bottom, and fully inserted in their slots.

Try to keep everything as straight and square as

possible.