The JAE12G2wasdesignedanddeveloped asaresultofajoint venturebetweenIMPBA Hall

ofFamememberRodGeraghty,DavidHall, RonZakerJr.&MartinTruexJr.

The maindifferencebetweenthishull andall theothersistheuseof sharpedgesonthe bottom

ofthesponsonsandtub,asopposedtocurved surfaces.Thishelpsbreakanysurfacetension

ofthewaterandmakesforafasterboat.

Thisdesignapproachhasbeenbuilt, developedand testedagreatdeal.

Inadditiontoamarineengine,youcanuseanyaircooled12, 15,18, 20(small block)caror

truggyengine, withexcellent results.

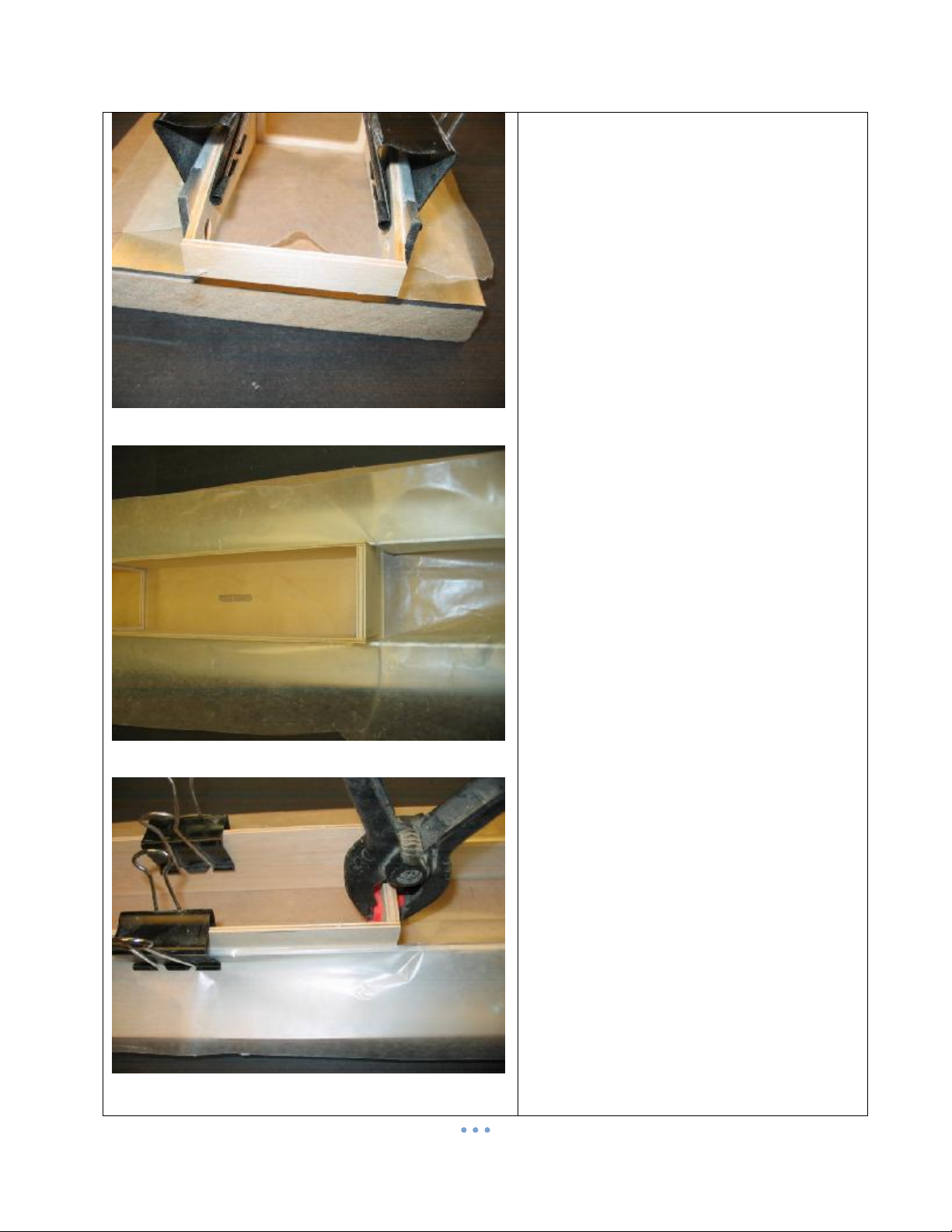

The kitisnothardtoassemble,asall of the hardstuff hasbeen doneforyou.

Thatisnoexcusetodo apoorjobwithassembly. The betteryoubuildthisboat,thebetteritwill

run.Often thedifferencebetweenan excellent buildingjobandapooroneisasimplesanding

block.

Anoteaboutoverhangs:

Thisboat isdesignedtoshearwaterandpreventanycapillaryactionof water. Todothisthe

tub, skiandsponsonshaverearoverhangs. Theseshearthewateroff and mustbeleftinplace

andnot rounded inanyway.

The boatalsohassideoverhangsonthe sponsons. Thesehelptheboat getuponplane

quicker. If youareusingapowerfulengine,youcansandtheseoff, but leaveall cornerssharp.

Takethetimetoreadthisentiremanual, sothat you arefamiliarwithall thebuildingsstepsand

theirproperorder. Takeyourtime; makesureyouunderstandeverythingbeforeyoudoitand

you will be rewardedwithanimpressiverunninghull…

Thiskit isnot atoy. Although R/Cboatingisafunandrewardinghobby,it canbedangerous

ifnot donewithcommonsenseand safetyinmind. Justaboutanyoneshouldbeableto

buildthiskit, butit shouldnot beoperated bychildren without closeadult supervision.

Themanufacturerassumesno liabilityfordamagesorotherloss intheuse ofthisproduct,as

wehavenocontrol overtheconstructionorend useofthisproduct.