P R O V E E

Before we can start building, we need to do some prep work. Good prep work

will pay off later with a straight, true running boat.

First, we need a flat work surface. Nothing else will do.

If you don’t have a perfectly flat bench, you can make one with a piece of

12x48 plywood.

Simply screw a couple of 2x4’s lengthwise to the bottom. Make sure the 2x4’s

are straight!

You can then put this on a bench, and shim the corners to make it steady.

Or, if you are really pressed for space, you can set it on a couple of saw

horses.

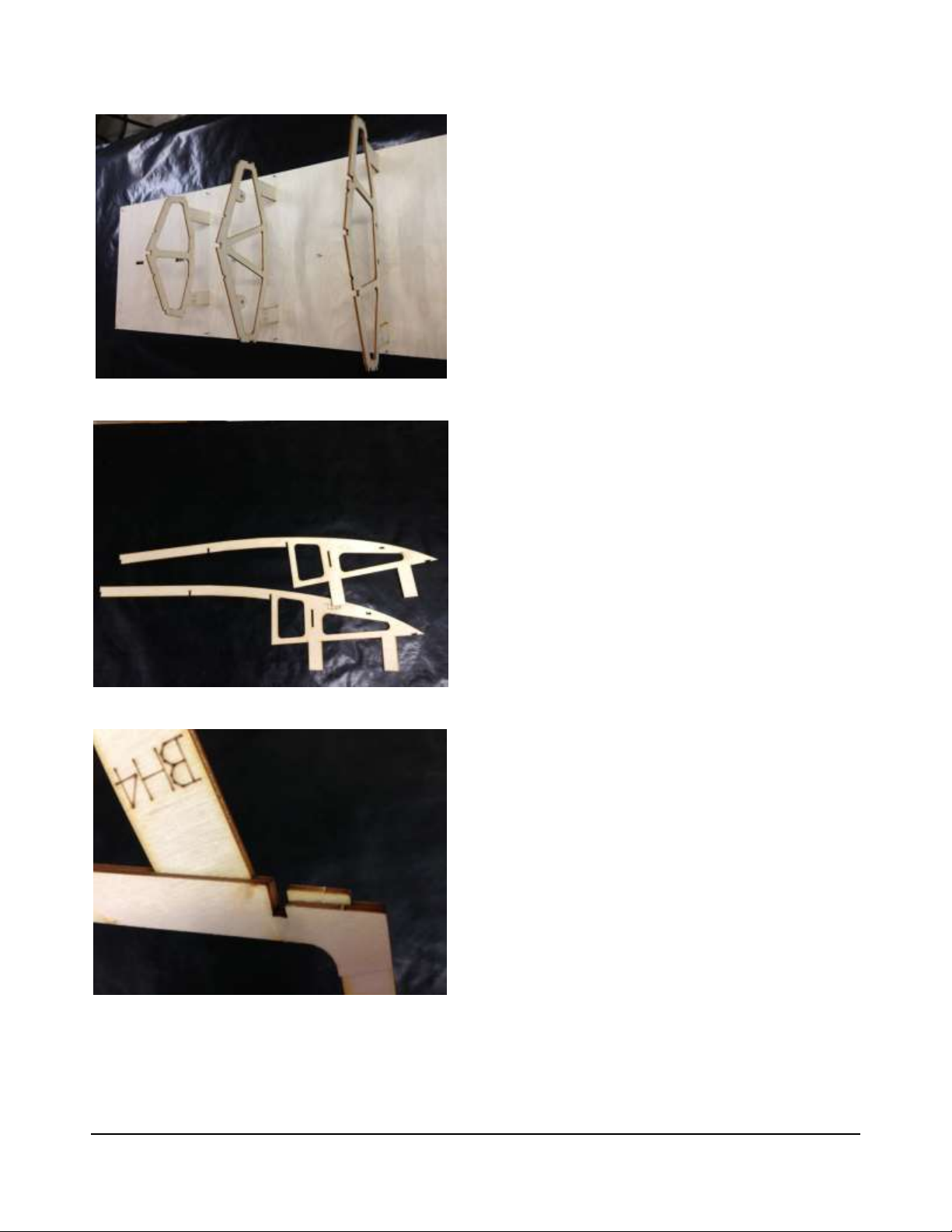

The Build

We are ready to start the build!

Remember- The boat is being built upside down. Any reference to the top or

bottom refers to the boat’s top or bottom. If you are going to attach something

to the top, it would be closest to the bench. Right and left are always as you

are sitting in the boat, or from the rear.

Got it? If not, stand on your head as you build.

Please note that in some of the pictures, the boat shown may look different from

yours.

This is because we make a whole series of boats that are assembled in exactly the

same way. Where it is important, we show the correct hull in the pictures.

Also, some of the pictures may be out of sequence with what we are doing. This is

to clarify a point.

Take your time, read ahead in the manual and understand what you are going to

do before you do it.

If you need assistance, we are here to help.