R I V E T T / R O C K E T T

Purpose

The Rivett and Rockett were designed to fill a void in the gas boat market.

There simply was not a scale type hydro specifically designed for gasoline

power.

The Rivett and Rockett were designed from the ground up as gas boats.

They were literally designed around a Zenoah marine engine!

They were designed as easy to build kits that are also easy to setup, and very

predictable to drive. They have excellent stability and turning ability, and

handle rough water as well as any hydro.

The secret to their outstanding performance is the modern design features,

such as the sponson angle of attack, non trip and deck crown. All these

elements add up to an aerodynamically sound design.

You can build this boat without having the engine or radio, but it does make it

easier to have them available when you build.

You can use any gasoline engine, as long as it has mounts for 5 inch rails.

If you use a Zenoah or similar, you will generally use a collet type of cable

system.

If you use a Homelite, or similar sport engine, you will generally use a square

drive type.

Please note that this boat was designed for the Zenoah style marine engines.

Other engines may not fit without cutting, and may not fit under the cowling.

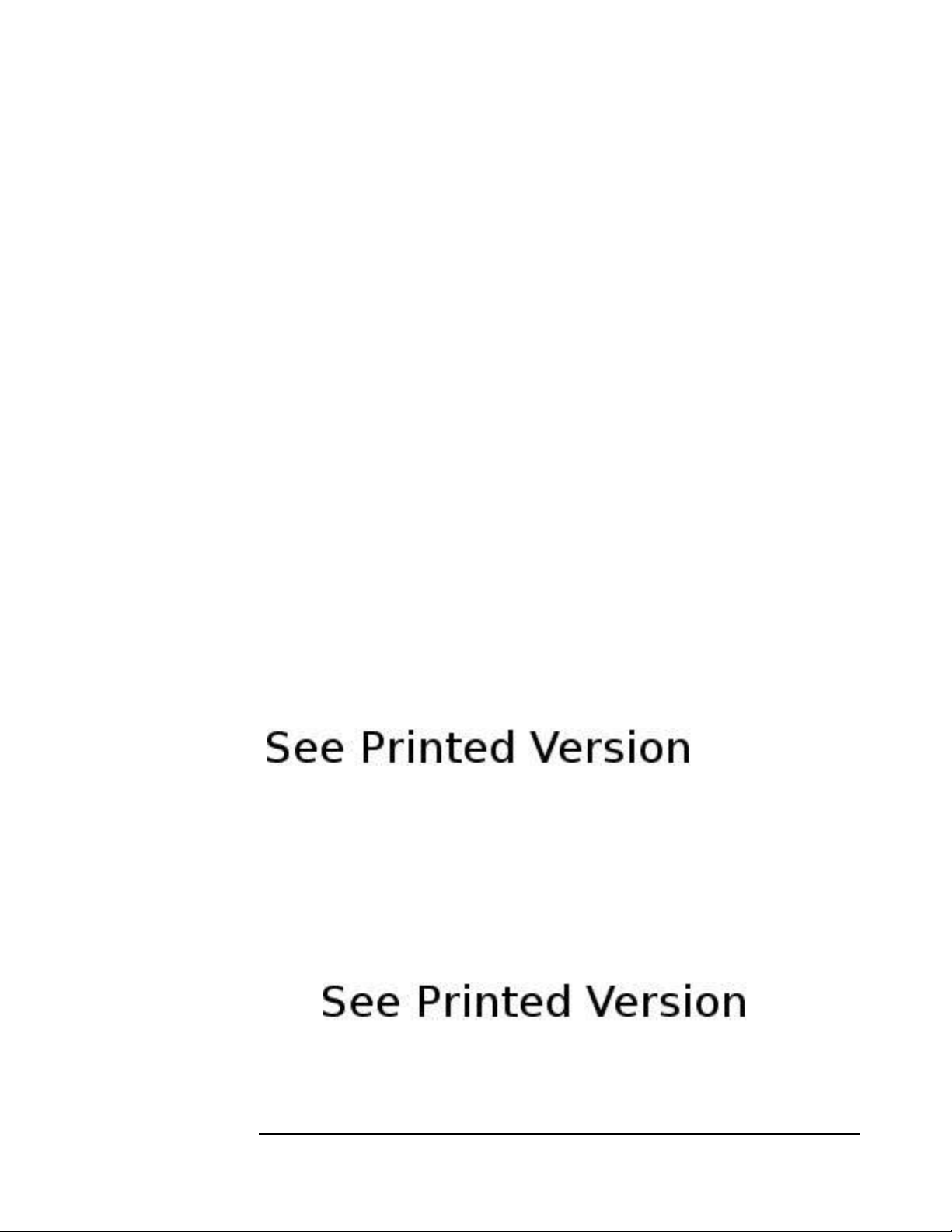

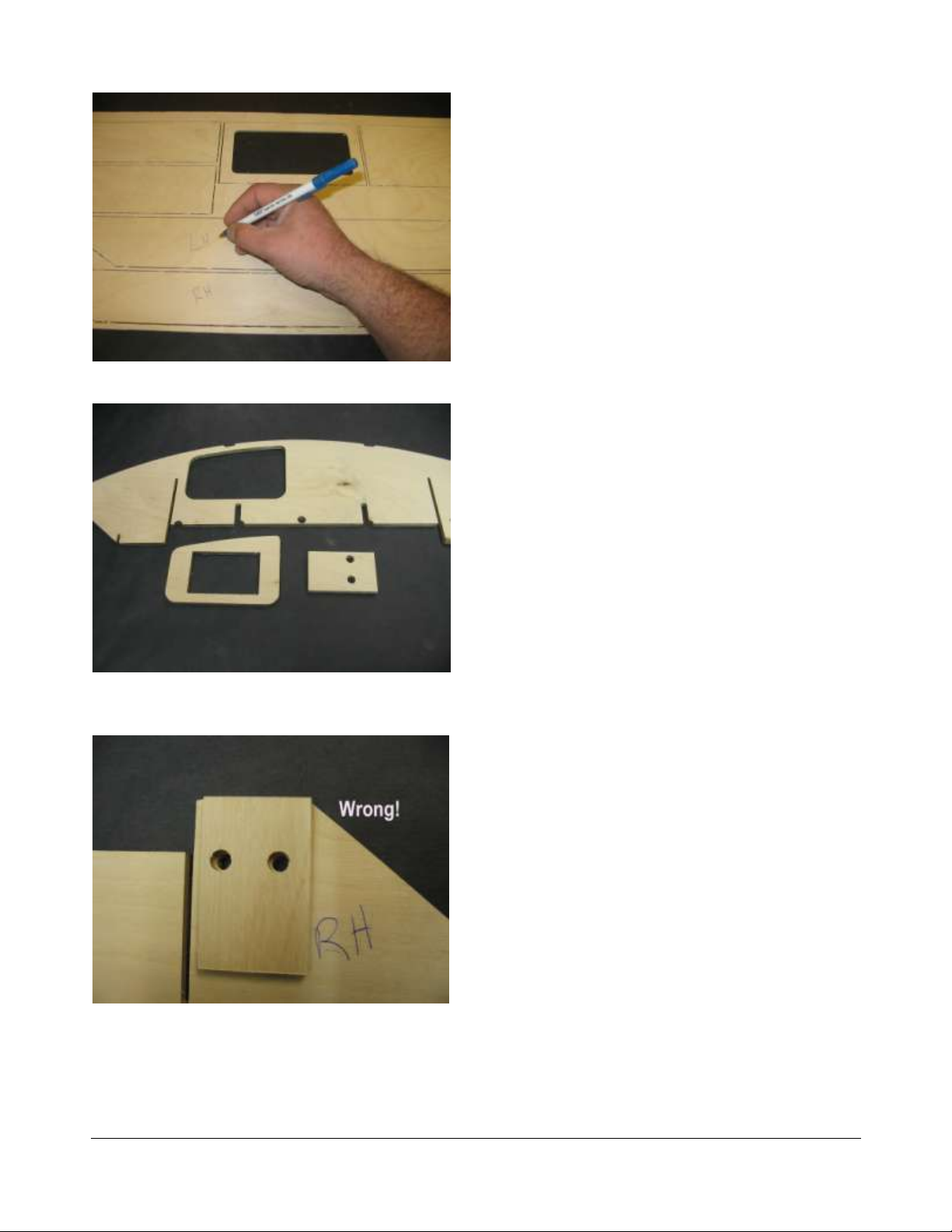

These kits are identical, except for the top decks. Construction is identical,

except for the top decks. Both the Rivett and Rockett are built exactly the same

way, and we show both decks.

This reduces our costs, as we only have to produce one manual for both kits.

You benefit because this keeps the kit price reasonable.