Guide 1

CONTENTS

8Contents..............................................................................................................................1

1Guide..............................................................................................................................2

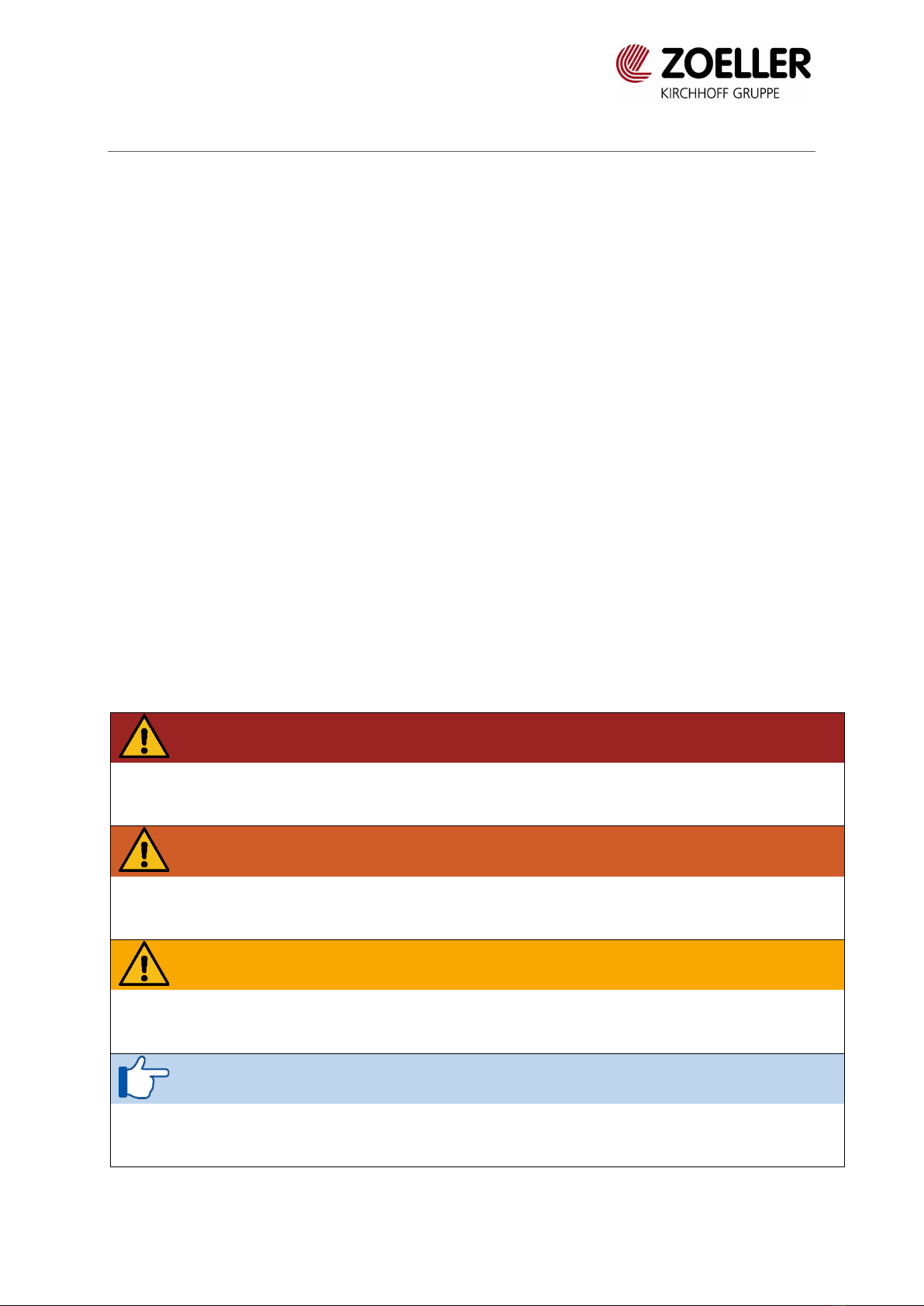

1. SYMBOLS USED IN THIS MANUAL............................................................................................................... 2

2Main components..........................................................................................................4

2.1 Terminal ZCS............................................................................................................................................ 4

2.2 ZCS-Command module....................................................................................................................... 5

3Operating.......................................................................................................................6

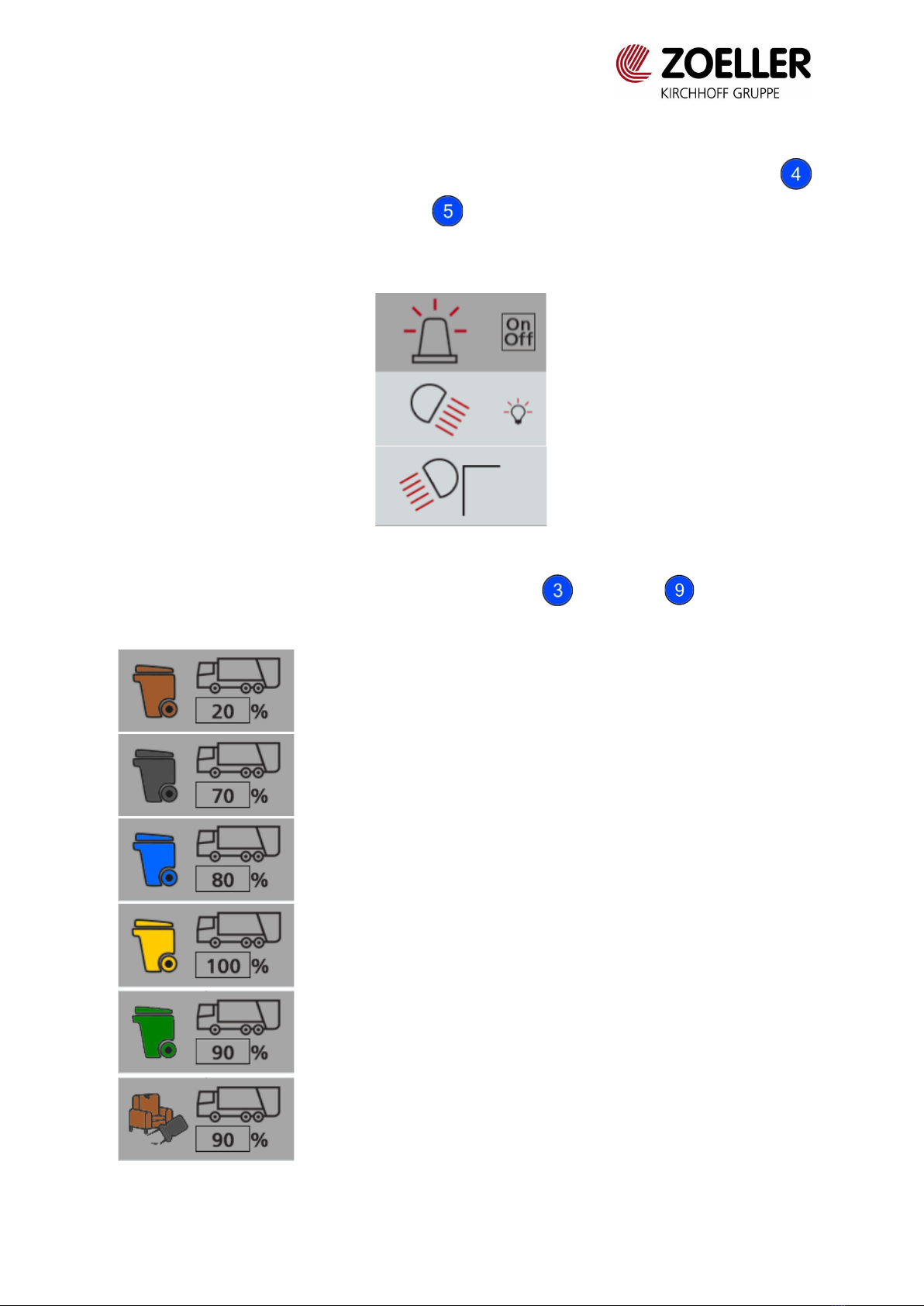

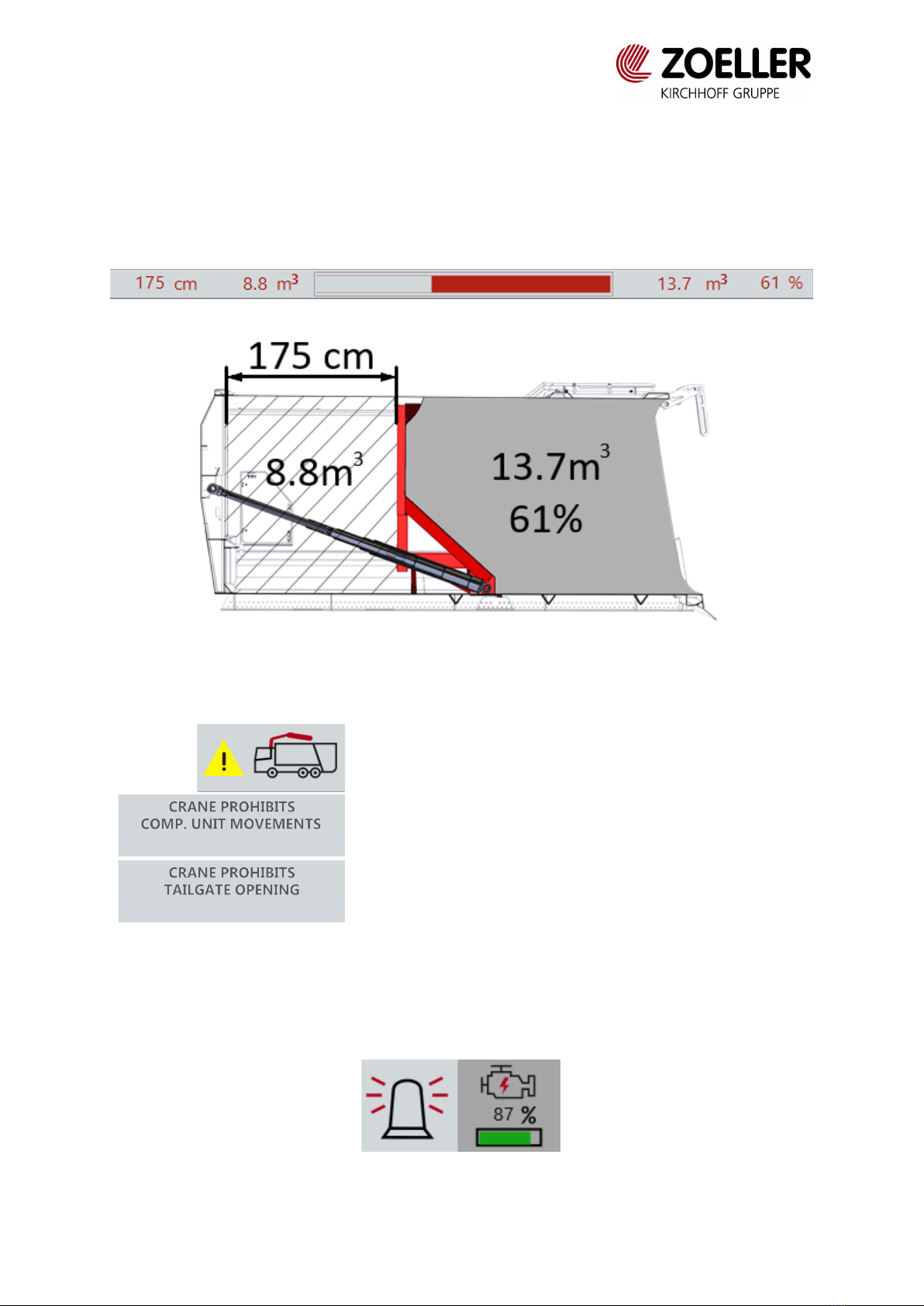

3.1 Main screen.............................................................................................................................................. 6

3.2 RCV Parameters ....................................................................................................................................10

3.3 Maintenance ..........................................................................................................................................11

3.4 Counter ....................................................................................................................................................12

3.5 Emptying .................................................................................................................................................13

3.6 Packing configuration.........................................................................................................................14

3.7 Lifter configuration..............................................................................................................................15

3.8 Video configuration.............................................................................................................................17

3.9 Other function configuration...........................................................................................................18

3.10 Calibration menu..................................................................................................................................21

3.11 Weighing system menu.....................................................................................................................21

3.12 Menu documentation.........................................................................................................................22

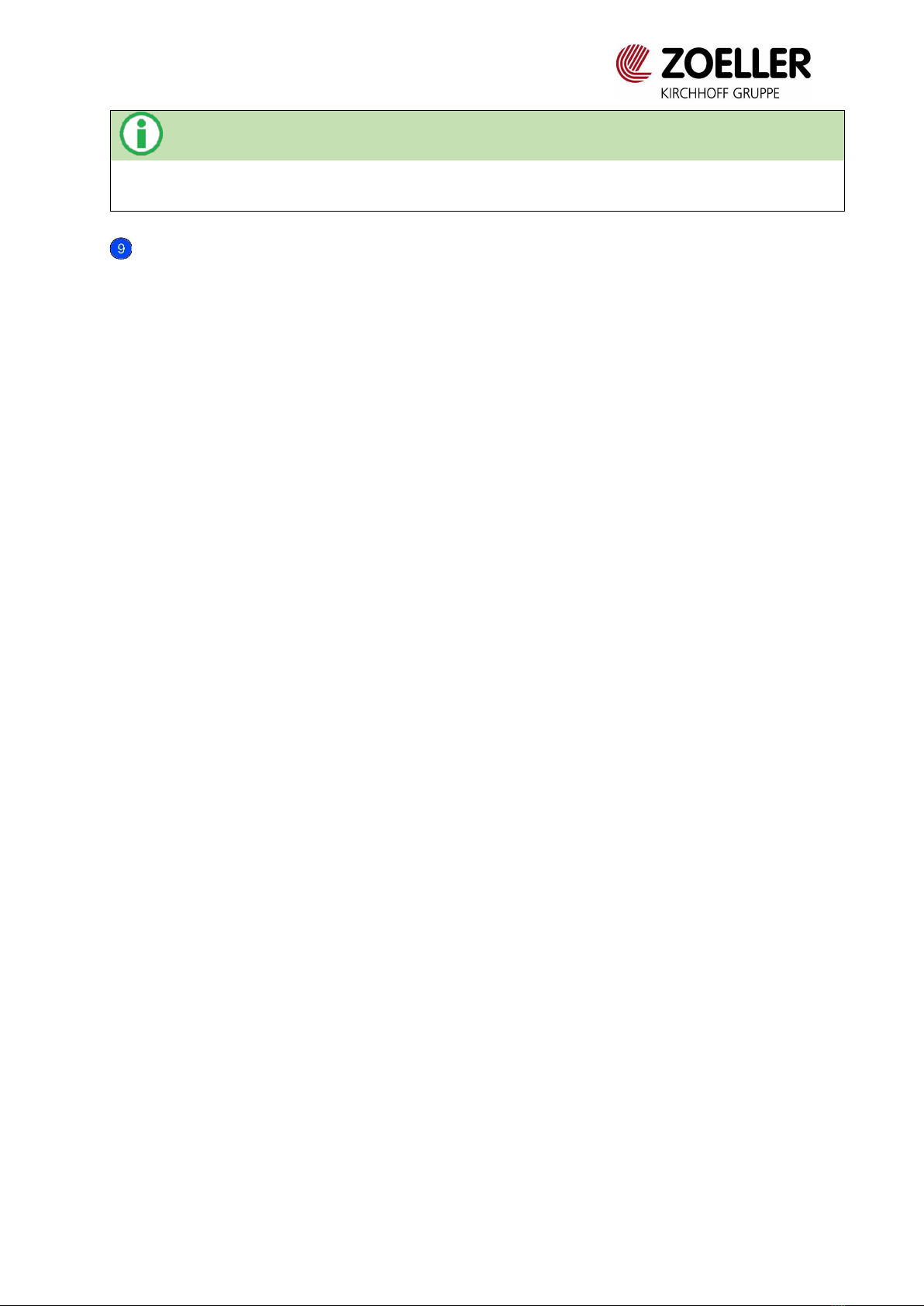

4Symbols........................................................................................................................23

5Error messages.............................................................................................................25