© Copyright 2014 Zoeller®Co. All rights reserved.

This utility pump is designed for general commercial and industrial

applications. Unit is designed for water, but is not submersible. For use

transferring liquids, emptying or lling tanks, sinks or bowls. Self-priming

to 7 ft. if the impeller is initially wet (primed). Intermittent duty. NOTE: Unit

DESCRIPTION

is NOT RECOMMENDED for use with soap detergents, gasoline, fuel oil,

ammable, explosive or combustible liquids or other uids not compatible

with pump component materials. Do not use unit in enclosed areas.

INSTALLATION

SK2206

1. Pump should be placed as close to source of liquid and power as

possible, not more than 7 feet above liquid source if self-priming,

and not more than 25 feet from power source.

2. Use reinforced plastic or fabric tubing or metal pipe for the suction

side of the pump. This will prevent collapse of the suction piping.

Discharge piping should never be larger than suction piping!

3. Attach suction line piping to the suction inlet and discharge line piping

to the discharge outlet.

4. Avoid using looped sections of pipe which might permit air to become

entrapped.

5. Piping should be checked for any leaks at the connections. Small

leaks in suction line greatly reduce efciency of pump, and may

prevent priming. (Never operate a pump unless it is secured to a

solid foundation.)

6. Do not operate pump dry. Impeller and seal damage will result.

7. Protect pump from extreme heat, cold, and humidity. This unit is not

waterproof and is not intended to be used in showers, saunas, or

other potentially wet locations. The motor is designed to be used in

a clean, dry location with access to an adequate supply of cooling

air. Ambient temperature around the motor should not exceed 104°F

(40°C). This unit is not weatherproof, nor is it able to be submersed

in water or any other liquid.

8. Install a foot valve and prime pump when suction lift is over six feet

or when suction line is longer than six feet.

9. Itisstrongly recommended that the Model311ispluggedintoa G.F.C.I.

(Ground Fault Circuit Interrupter). Consult your local electrician for

installation and availability.

OPERATION

1. Model 311 is self-priming and should prime itself within 30 seconds

after pump is started. Wetting impeller with pumped uid and keeping

the impeller coated with petroleum jelly will lengthen its life and

improve priming action. Running the impeller dry for as short as 30

seconds can ruin the impeller (Ref. No. 5). Keep suction line as short

as possible.

NOTE: An easy way to prime the pump (wet impeller), if using a garden

hose, is to ll the discharge hose; elevate the discharge hose slightly to

retain water and start the pump. Another method would be to disconnect

the discharge hose from the pump, making a U-bend of the discharge

hose, ll the hose and then reconnect to the pump (without losing the

water). In both cases, the water behind the impeller will seal the pump

and it will prime almost immediately.

2. Be sure hose attachments or piping connections are tight. Any

leakage in suction side will prevent pump from priming.

MAINTENANCE

1. Always drain pump when not in use.

2. If pump is not going to be used for a month or longer, ush with fresh

water and remove body cover, take impeller out, clean inside body

and apply generous coating of petroleum jelly to both inside body and

impeller before replacing impeller in body.

3. Pump should be checked daily, weekly, monthly, etc. for proper

operation. If anything has changed since unit was new, unit should

be removed and repaired or replaced. Only qualied electricians or

servicemen should attempt to repair the motor of this unit. Improper

repair and/or assembly can cause an electrical shock hazard.

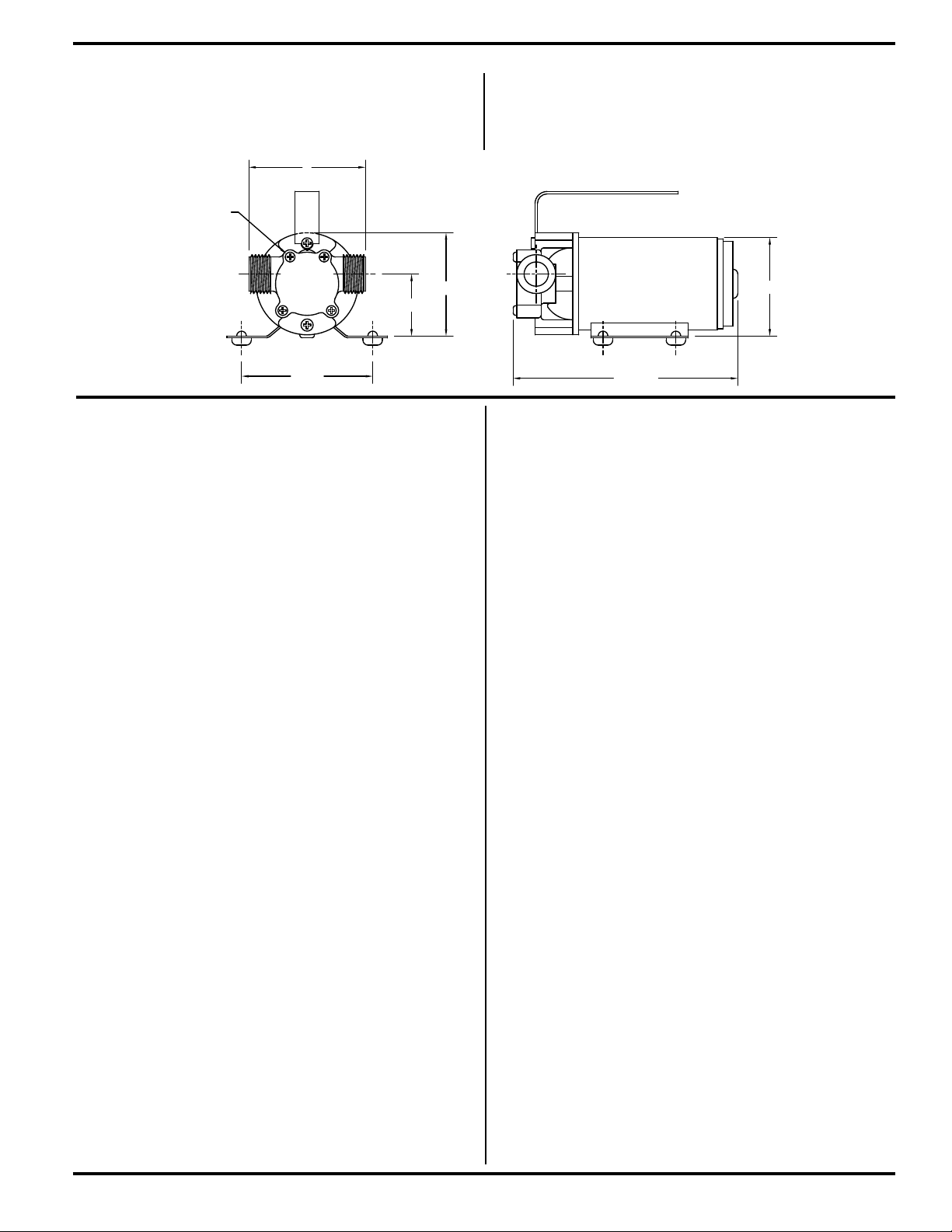

HOW TO REPLACE IMPELLER

Replace impeller when it has been worn or damaged by foreign objects,

pumping improper liquid or dry running.

1. Remove four screws at “A” (see gure above).

2. Remove cover plate.

3. Using your ngers, remove damaged or worn impeller.

4. Clean the inside of the pump head and remove any foreign materials

which will obstruct the impeller’s operation.

5. Apply petroleum jelly or similar lubricant to both the inside of pump

head and to the outside diameter of the impeller.

6. Align the at on the inside of the new impeller with the at on the motor

shaft. Push into place while twisting blades in a clockwise direction.

7. Place new gasket on pump body face, align holes and replace cover.

8. Tighten all four screws evenly and snugly.

9. Replacementimpeller/gasket kits areavailableas part number015391.

"A"

2 17/32

5 25/32

3 3/8

3

1 19/32

2 21/32