© Copyright 2006 Zoeller Co. All rights reserved.

PREINSTALLATION CHECKLIST

1. Inspect your pump assembly. Occasionally, products are damaged during

shipment. If the unit is damaged, contact your wholesaler before using.

2. Carefully read the literature provided to familiarize yourself with specific

details regarding installation and use. These materials should be retained

for future reference.

3. Check to be sure your power source is capable of handling the voltage require-

ments of the motor, as indicated on the pump name plate and literature.

4. Make sure the pump electrical supply circuit is equipped with fuses or circuit

breakers of proper capacity.Aseparate branch circuit is recommended, sized

according to the “National Electrical Code” for the current shown on the pump

name plate and literature.

5. See CAUTIONS & WARNINGS on FM1239: 820 GRINDER INSTALLATION

INSTRUCTIONS.

NOTE: If you do not know the pump-out cycle time, record it from the

closest pump unit with similar head requirements or higher. (See 20

below)

TYPICAL REPLACEMENT INSTALLATION

1. Electrical wiring and enclosures must be in accordance with the “National

Electric Code” and any other applicable state and electrical requirements.

2. ELECTRICAL PRECAUTION-Before servicing a

pump always shut off the main power breaker - making sure you are

wearing insulated protective sole shoes and not standing in water.

Under flooded conditions, contact your local electrical company or a qualified

licensed electrician for disconnecting electrical service prior to pump removal.

Refer to the original installation/service manual for any precautions that

need to be obeyed, ie: pump may have more than one electrical supply

connection.

3. If installation is outdoors, locate tank riser and unlock and raise hinged riser

lid. For indoor installations, this step is not required.

4. After you shut off the power, open electrical enclosure or electrical disconnect

to separate pump power lead, and signal leads. Coil wires and lay them to

the side and keep dry.

5. Close ball or gate valve in discharge line and then disconnect the quick

disconnect assembly.

6. Loosen the twelve (12) captive 5/16” bolts that retain the grinder pump

core.

7. Attach lifting cable or rope to the two (2) pump core eye bolts. Carefully raise

pump core straight up and out of the basin. Set old pump core down and

remove lifting cable.

8. Prepare your Zoeller grinder pump assembly for installation by removing all

packing materials including the white nylon ties that are holding the alarm

float and pump control float to the suspension pipe and discharge pipe. Do

not remove the large black nylon tie that is securing the control float to the

discharge pipe.

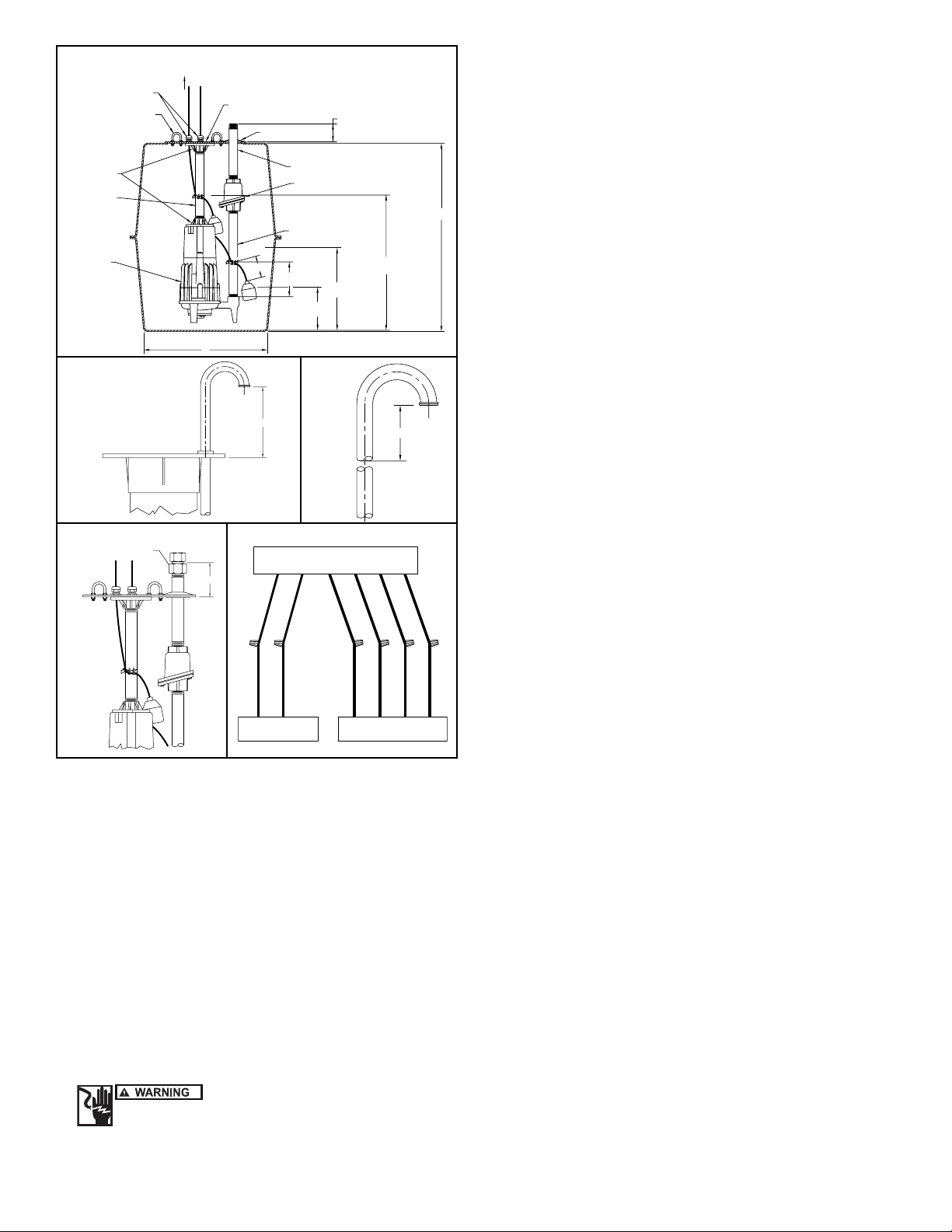

9. For application with an electrical quick disconnect and a gooseneck discharge

pipe, Zoeller Company adapter kit P/N 10-1196 will simplify installation.

Measure distance from underside of pump plate to gooseneck outlet. See

Figure 2. Record measurement. Place adapter fitting on 1¼” discharge pipe

of the new replacement pump. Measure the distance from the underside of

the replacement plate to the bottom of the internal socket of the adapter fitting.

See Figure 4. Record measurement. Subtract the second measurement from

the first and mark gooseneck with this figure. See Figure 3. Cut old gooseneck

discharge line at this location. Transfer gooseneck pipe to the replacement

grinder and tighten adapter fitting. Place old pump core out of the way.

10. Verify the correct pump “On” height by measuring the height from the threaded

discharge to the top of the black nylon tie securing the pump control float

(6¾” - See figure 1). Also verify the distance from the control float to the small

nylon tie that is secured to the black nylon tie mentioned above (3½” - See

fig. 1). Adjust if necessary. With tethered as figured, the pump will turn on at

approximately 16”.

11. Alarm Float Switch is set at factory to turn “On” at 27”. To change the “On”

level, refer to FM0419; Variable Level Float Switch Installation Instructions.

NOTE: Float switches must be positioned so that they will be free of

any object in the tank and the tank walls.

12. Attach lifting cable or rope to the stainless steel U-bolts on the pump plate.

13. Place sealing foam with pressure sensitive adhesive on the underside of the

pump plate. Center the sealing foam over the holes around the edge of the

pump plate. Using a pencil or pen, poke holes thru the sealing foam using

the holes in the pump plate as a guide. Clean off pit where the pump plate

sits.

14. Lower unit into basin being sure to line up the quick disconnect fittings and the

bolt holes. Start all twelve (12) bolts (supplied) with washers (supplied) under

the bolt heads. After all bolts have been started, the bolts can be tightened.

Engage the quick disconnect, tighten if required, and open the ball or gate

valve in discharge pipe.

15. Change out the UF cord seals in the electrical enclosure with cord seals

supplied to accept cordage.

16. Thread pump power cord and alarm float switch cord through the cord seals

and into the electrical enclosure. Zoeller Company adapter kit P/N 10-1195

will simplify installations with an electrical quick disconnect. Installation with

electrical quick disconnect fitting will require the following operations. Cut

six conductor cable leading from tank wall directly above the electrical quick

disconnect fitting. Strip outer cord jacket back three (3) inches from end

being sure not to nick individual conductors. Thread the 6 conductor cables

through the largest cord seal and into the junction box. Thread the pump cord

and float switch cord through the remaining cord seals and into junction box.

Using the wire nuts provided, connect the wires per Figure 5.

17. Connect pump power cord and alarm float switch cord to their respective

terminations.

18. Check control panel for relay current/power specifications. If too low, change

relays or rewire as required for the amps on the name plate or catalog

sheet.

19. Replace electrical enclosure cover. Turn main power breaker on.

20. Fill basin and allow unit to cycle (on-off). Time the pump-out cycle. The cycle

should be at or less than the recorded cycle time.

21. For outside installations, hinged cover should now be shut and locked.

Installation is now complete.

22. For future service and repair information refer to FM1239 (820 Installation

Instructions).

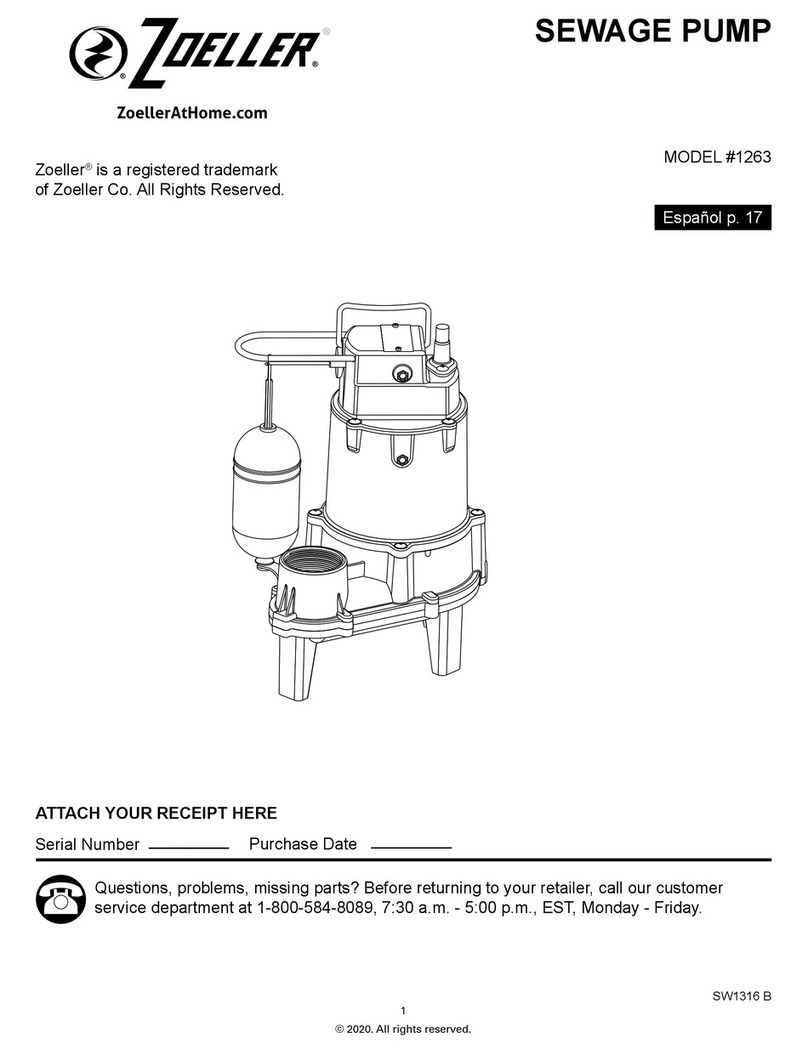

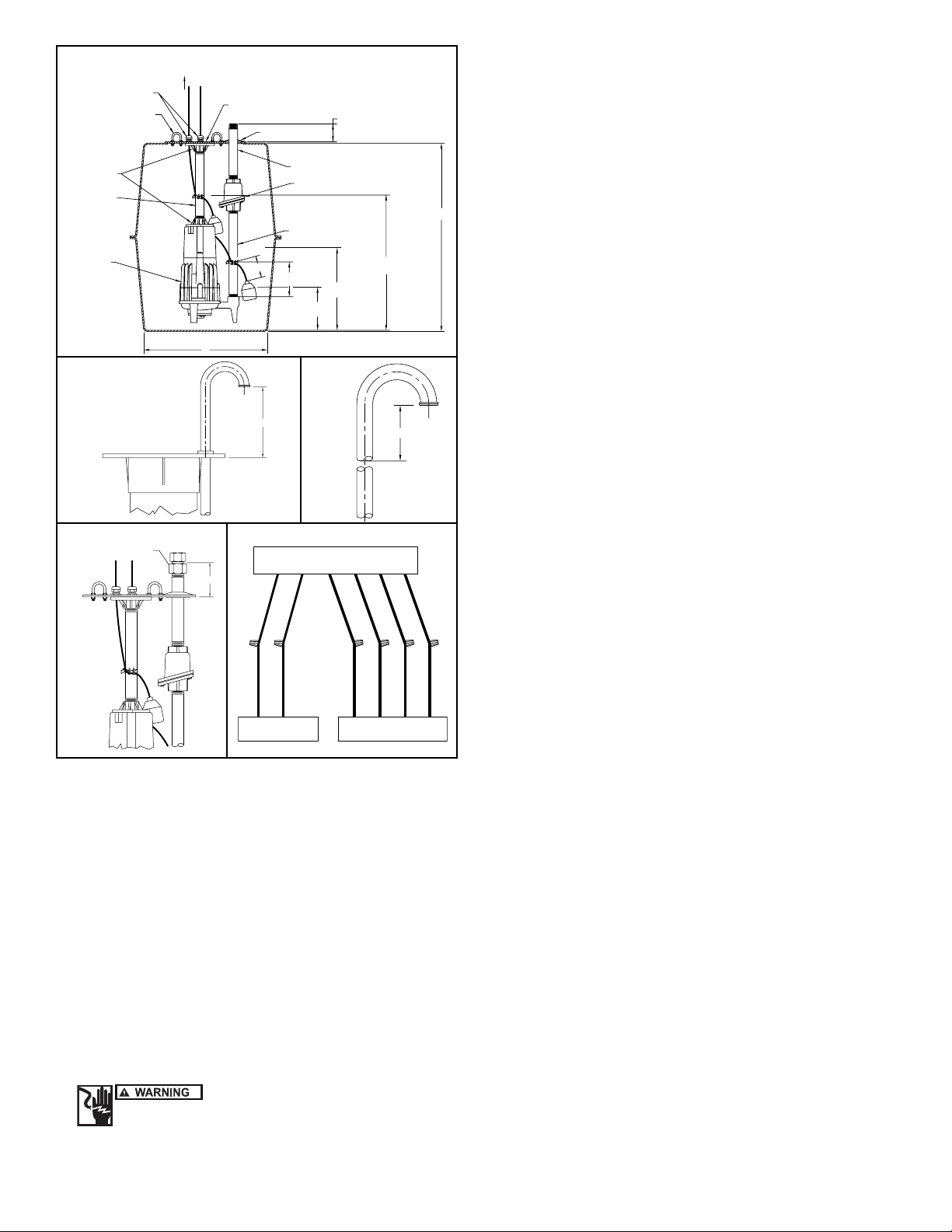

FIGURE 1 TYPICAL INSTALLATION - WD820 & WH820 MODELS

FIGURE 2 FIGURE 3

FIGURE 4 FIGURE 5 - AUTOMATIC/MANUAL MODELS

SK1864C SK1864D

SK1864A SK1864B

SK1714

GALVANIZED PIPE

GRINDER PUMP

FULLY AUTOMATIC

200V-230V, 1PH, 2HP

APPLICATION; FACTORY SET AT 27")

(ALARM, FIELD VERIFIED PER

24"

3 1/2"

6 3/4"

ON

OFF

16"

8 3/8"

GALVANIZED PIPE

1 1/4" X 14"

5/16" 304 STAINLESS STEEL

CAST IRON ADAPTERS

ELECTRICAL CORDS TO PANEL OR JUNCTION BOX

EPOXY COATED PUMP PLATE

15 3/4" X 1/4" STEEL

CORD SEAL

LIFTING BOLT

(FLOAT SWITCHES SHOWN

GALVANIZED PIPE

1 1/4" X 11"

CAST IRON CHECK VALVE

1 1/4" FEMALE NPT

ORIENTATION WILL VARY.)

1 1/4" X 17"

HERE FOR CLARITY. ACTUAL

1 1/4" GROMMET SEAL

3 1/2"

36 1/2"

A

A-B

B

ADAPTER FITTING

BLACK

WHITE

GREEN

RED

WHITE

BLACK

ORANGE

BLUE

GREEN

RED

WHITE

BLACK

6 CONDUCTOR TRAY CABLE

2 CONDUCTOR

ALARM CORD

4 CONDUCTOR

PUMP CORD