© Copyright 2010. All rights reserved.

2

Manufacturerwarrants,tothepurchaserandsubsequentownerduringthewarranty

period, every new product to be free from defects in material and workmanship

under normal use and service, when properly used and maintained, for a period

of one year from date of purchase by the end user, or 18 months from date of

original manufacture of the product, whichever comes first. Parts that fail within

the warranty period, one year from date of purchase by the end user, or 18

months from the date of original manufacture of the product, whichever comes

first, that inspections determine to be defective in material or workmanship, will

be repaired, replaced or remanufactured at Manufacturer's option, provided

however,thatby so doing we will not be obligatedto replaceanentireassembly,

the entire mechanism or the complete unit. No allowance will be made for ship-

ping charges, damages, labor or other charges that may occur due to product

failure, repair or replacement.

This warranty does not apply to and there shall be no warranty for any material

or product that has been disassembled without prior approval of Manufacturer,

subjectedtomisuse,misapplication,neglect,alteration,accidentoractofGod;that

hasnotbeeninstalled,operatedormaintainedinaccordancewithManufacturer's

installation instructions; that has been exposed to outside substances including

but not limited to the following: sand, gravel, cement, mud, tar, hydrocarbons,

hydrocarbonderivatives(oil,gasoline,solvents,etc.),orotherabrasiveorcorrosive

substances,washtowelsorfemininesanitaryproducts,etc.inallpumpingapplica-

LIMITED WARRANTY

tions. Thewarrantysetoutintheparagraphaboveisinlieuofallotherwarranties

expressedorimplied;andwedonotauthorizeanyrepresentativeorotherperson

to assume for us any other liability in connection with our products.

ContactManufacturerat, 3649 CaneRunRoad,Louisville,Kentucky 40211,At-

tention:CustomerServiceDepartmenttoobtainanyneededrepairorreplacement

of part(s) or additional information pertaining to our warranty.

MANUFACTUREREXPRESSLYDISCLAIMSLIABILITYFORSPECIAL,CON-

SEQUENTIALORINCIDENTALDAMAGESORBREACHOFEXPRESSEDOR

IMPLIED WARRANTY;ANDANY IMPLIED WARRANTY OF FITNESS FORA

PARTICULAR PURPOSEAND OF MERCHANTABILITY SHALL BE LIMITED

TO THE DURATION OF THE EXPRESSED WARRANTY.

Some states do not allow limitations on the duration of an implied warranty, so

theabovelimitationmaynotapplytoyou.Somestatesdonotallowtheexclusion

or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights

which vary from state to state.

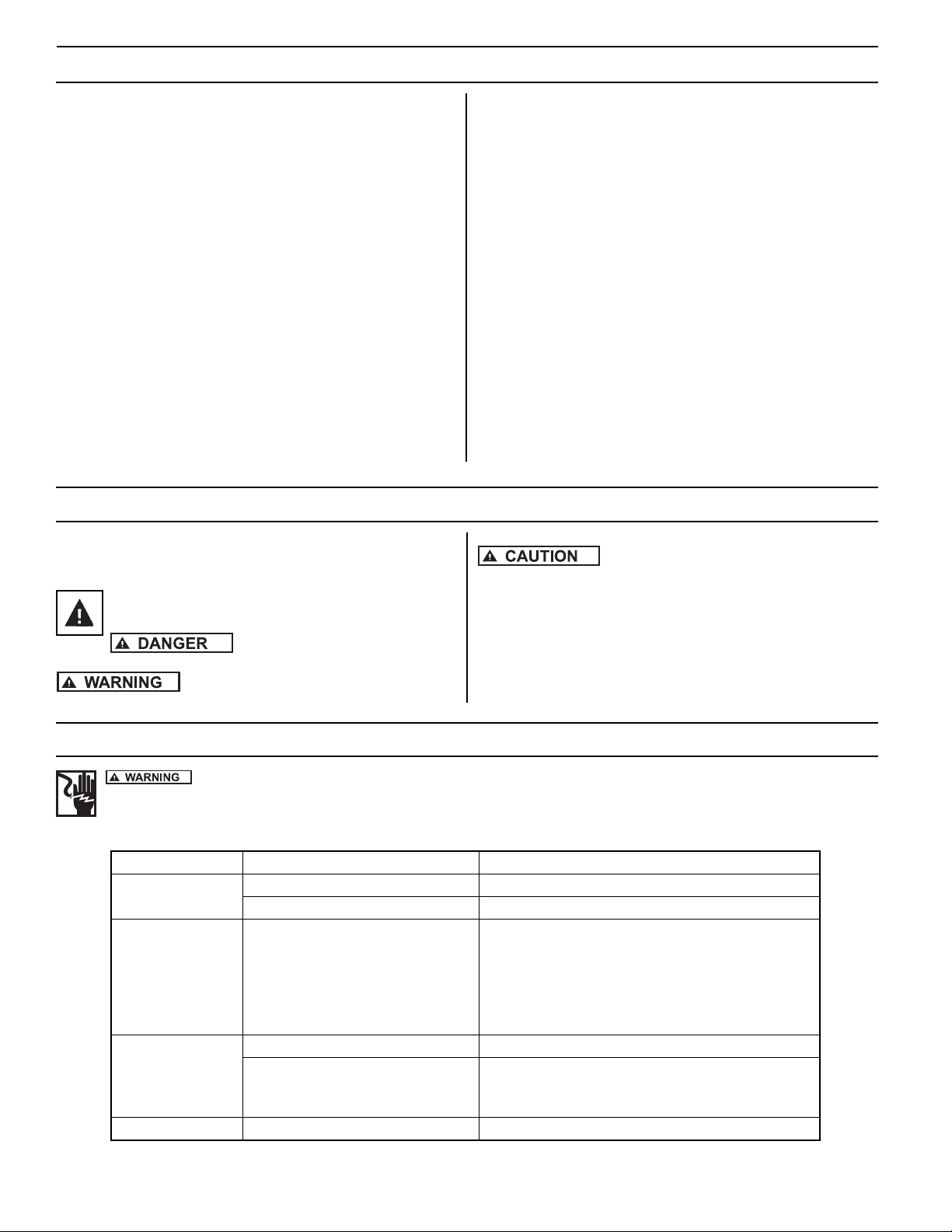

ELECTRICAL PRECAUTIONS - Before servicing a pump, always shut off the main power breaker and then unplug the pump. Make

sure you are not standing in water and are wearing insulated protective sole shoes. Under flooded conditions, contact your local electric company or a

qualified licensed electrician for disconnecting electrical service prior to pump removal.

TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Unit won’t run. Circuit breaker tripped. Reset circuit breaker.

GFCI tripped. Reset GFCI.

No or low spray. Blocked screen or nozzle, missing

or damaged o-ring, or incorrectly

installed nozzle.

Disconnect power. Clean screen and/or nozzle.

Check that o-ring is undamaged and seated in

groove. Check that nozzle is installed properly

(nozzles are marked “This side up”). Check depth of

pond. If less than 5 feet deep, move to deeper sec-

tion. Restart unit.

GFCI trips. Electrical storm can trip GFCI. Reset GFCI.

Short in system. Disconnect power and check cord for damage. If

cord is damaged contact Customer Service Help

Line at 1-800-928-7867.

Unit spins. Anchor rope loose. Check anchor rope and re-attach if necessary.

SAFETY INSTRUCTIONS

Carefully read and follow all safety instructions in this manual and on

pump. Keep safety labels in good condition. Replace missing or damaged

safety labels.

This is a SAFETY ALERT SYMBOL. When you see this symbol on

thepumporinthe manual,look for oneofthe following signal words

and be alert to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property damage if ignored.

Warns of hazards that CAN cause serious personal

injury or death, if ignored.

Warns of hazards that MAY cause minor personal

injury, product or property damage if ignored.

IMPORTANT: Indicates factors concerned with operation, installation, assembly

or maintenance which could result in damage to the machine or equipment if

ignored.

NOTE: Indicates special instructions which are important but are not related to

hazards.