·

..,

START ON

1.

Fill oil cup A,

be

sure oil goes into smooth,

1f

rot

, remove obstruction.

2. Push

in

E and turn the machine by hand for a

few

revolu1ions to make sure the oil is spread overcontact

surfaces.

3. The sharpener must

be

always up in locked position when starting.

BE CAREFUL

a. Keep the machine in warm place in cold weather.

b.

Repeat short

on

&

off

before permitting the machine to run

cont

inuously lor preventi

ng

excessive friction

between contact surfaces.

c.

Do

not use too much oil.

Do

not

use sewing machine oil.Use a least good grade

of

No.

30

motor oil.

d. In case your cutter is of DUAL SPEED TYPE, please take care of

the

fo

ll

ow

i

ng

two

po

ints:

(1) Be sure to

se

l

ect

the

swi1ch

to the upper high speed (HI) in starting,

and

then, when full

revolution has been attained, to

the

lower

speed

(LO)

The switch is put off

by

selecting the intermediate

OFF

(2) The continuous operation at low speed (LO) should

be

no

more than

30

minutes.

DO

NOT

OPERATE FOR

MORE

THAN

30

MINUTES.

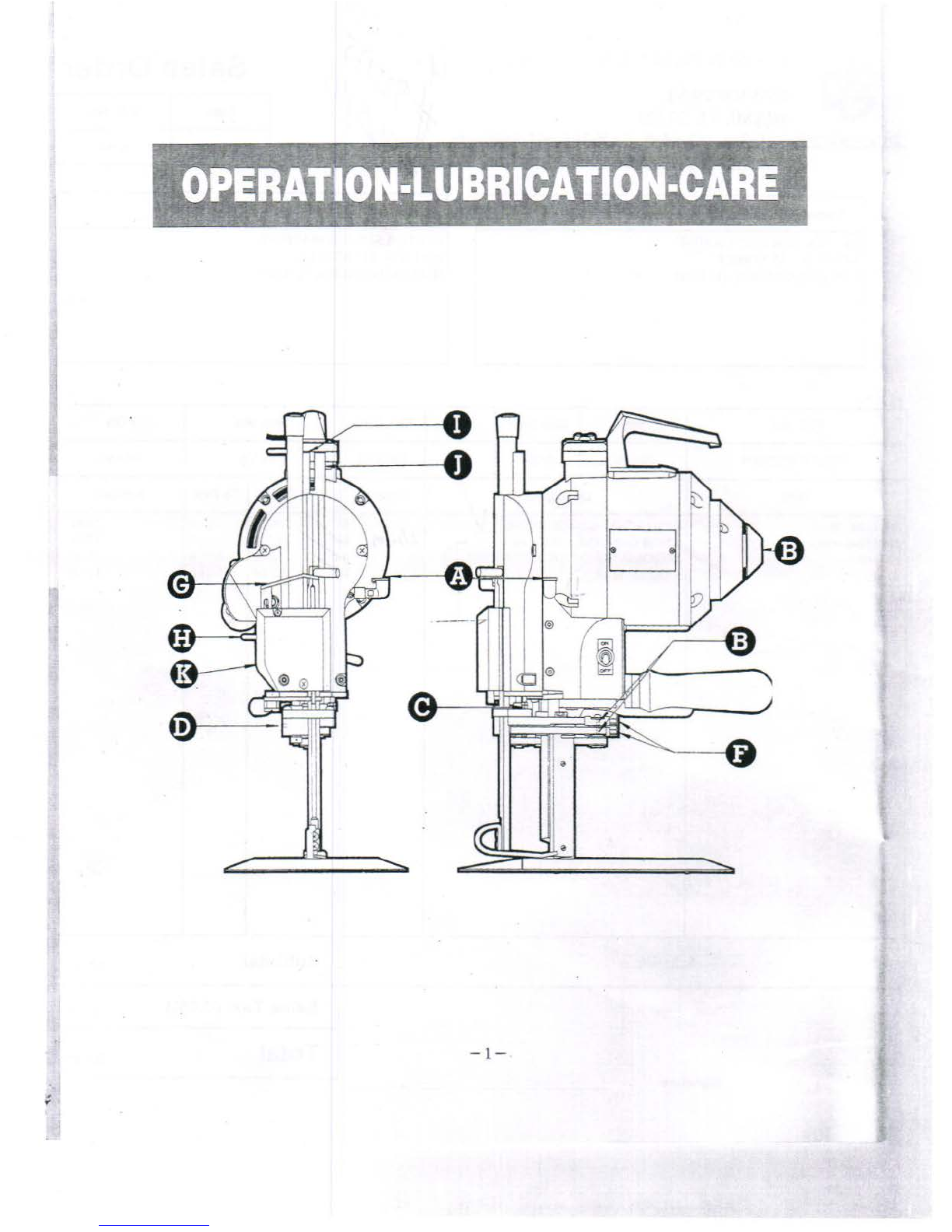

LUBRICATION

1.Fill

oi

l

ta

nk

A

One

dr

opoil

to

:

(no

need

to

oi

l 1

Tubes-1

& J

at connecting r

od

2.Turn

Knob·E

beanng) 3.

Pulley

Shatt-C

4.

8e

lt

Pu

ll

eys-B

SHAPENER OPERATION

1. Put the machine away from pil

es

of material.

2.

Drop pressure foot

by

lever located next to operating handle

3. Press lever G downward firm but not too quick.

BE CAREFUL

a.

Do not operate sharpener without knife in machine.

b.

Do

not operate sharpener with cutting material laid in machine.

c. Do not

sh

ut

off

motor

wh

ile sharpener is in moti

on

.

Remove

0 plug

and

insert

grease

tube

.Gi

ve

apea·

s1

ze

amount

to

the

o

pem

ng.

d.

If lever G is locked in ha

.l

fway

by

too

qu

ick operati

on

, lift lever H to

un

lock and start again.

CARE

1. Blow li

nt

out

of

mo

tor and sharpener

by

blower

or

something alike

tw

ice a week.

2.

Lint around screw mechani

sm

of sharpenerinside cover K

must

be

cleaned once a week.

3. Clean the kni

fe

slide by slot cleaner once a day.

4. Ramove lint from rollers

In

base plate.

To

prevent undue accumulation of lint,

do

not oil plate rollers.

If

rollers

stick

~

remove from plate and wash in cleaning solvent.

-

2-