To: Sales Order:

Number:

Date:

PO:

B.N.W. Industries Terms:

7930 N. 700 E. Amount

Tippecanoe, IN. 1

46570 USA

Office 574-353-7855

Fax 574-353-8152 Gas safety and modulating control valves

Web www.belt-o-matic.com Belt wiper product spreader, two 1-Hp drives

Mild steel construction, insulated, Zoltec Blue

Auto fines clean out in bottom plenum of dryer, 1-Hp drive

No pre--wired electric control panel

No variable speed drives for motors

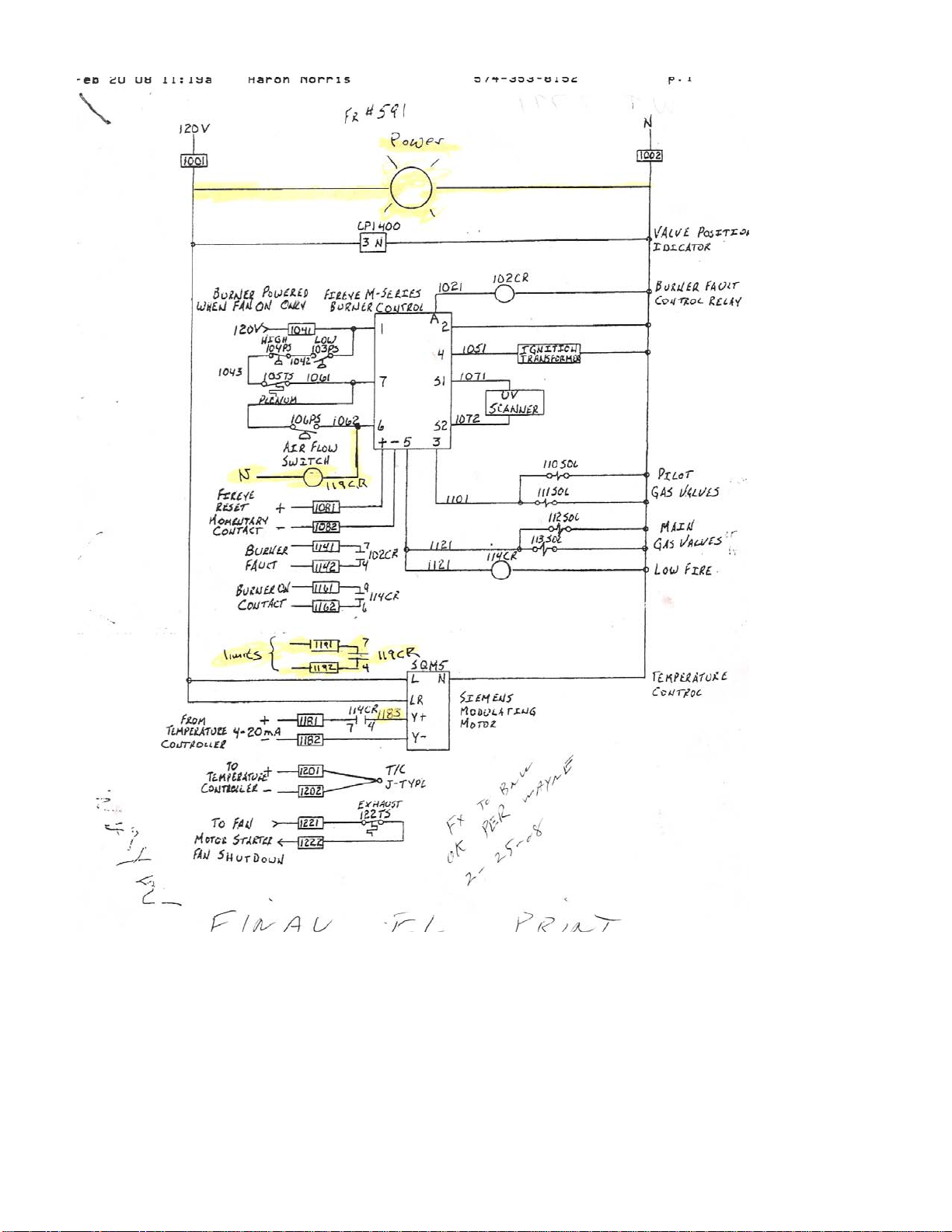

Fireye "M" series flame monitor, dwyer vacuum airflow

switch, ignition transformer, electric jct box (NEMA 4),

Important Note

% Down 35%

Entered By

Aaron Norris Total

Down Pmt

Received By: Balance

Date:

-$

All Prices in US Dollars

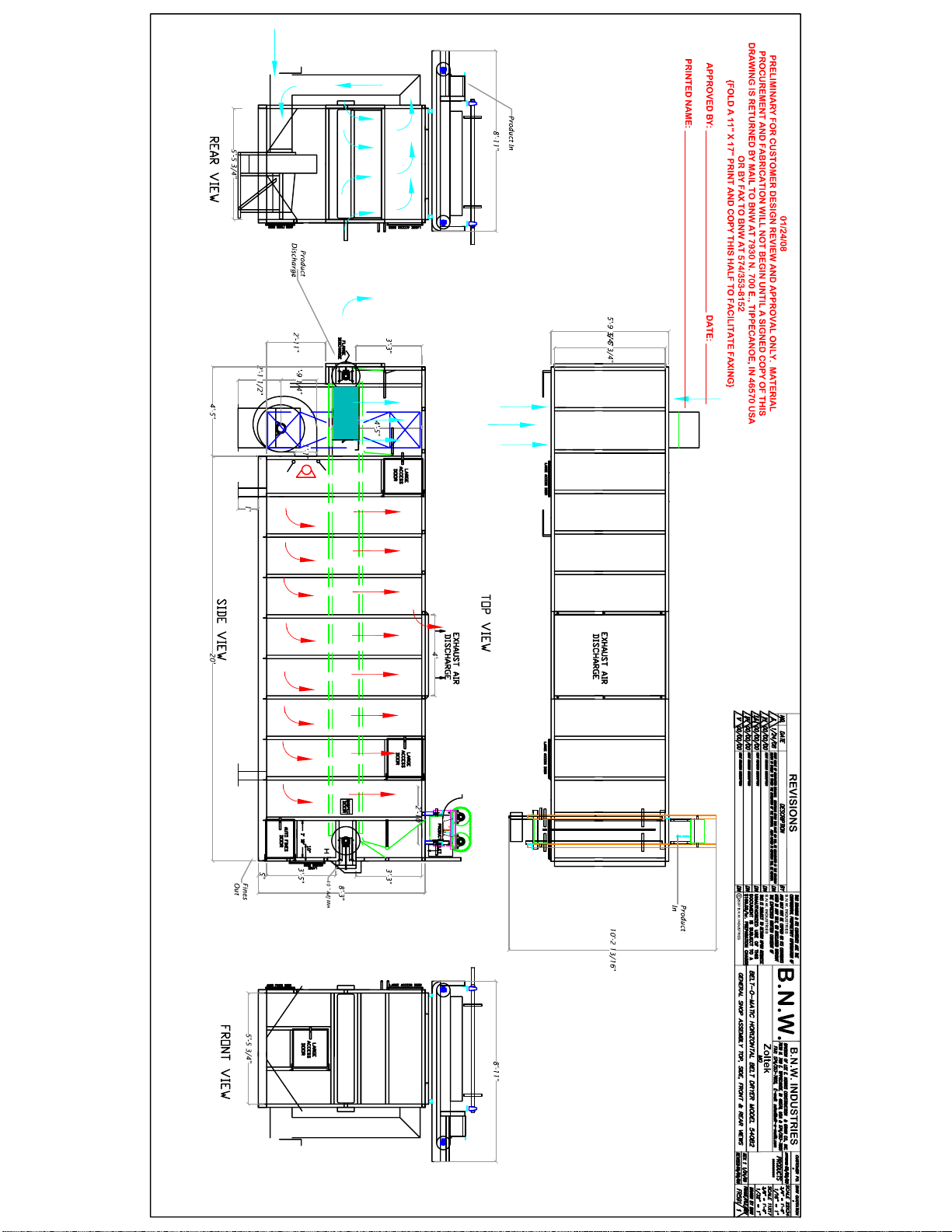

5' wide x 24' long, single-pass air up dry and cool

Belt-o-matic model 5-303B carbon pellet dryer/cooler

FOB Tippecanoe, IN, 46570. Allow 10 weeks ARO. Dated Required 2/15/08

35% down, 50% when ready to ship, 15% 30 days.

Description Price

Zoltec Corporation

Clancy Duttlinger

3101 McKelvey Road

St. Louis, MO. 63044

Product feed and discharge conveyors and fines discharge conveyor

and typical wiring scehmatic.

Not included

Air intake air duct

Motor controls for spreader, auto fines, and combustion blower

122670

All quotes are good for 30 days

Transportation, installation, and foundation

Electric power and gas supply

Pre-wired electric control cabinet

Temperature controller and thermocoupler

Variable speed drives for fan and conveyor motors

X

07247R3

1/7/2008

High temperature limit switches & dial temperature thermometers

Perforated plate conveyor belt with 0.078 x 0.156 slots, 304SS

3-Hp NYB combustion blower series 20 GI fan, 2500 CFM

3/4-Hp conveyor drive

TEFC premium efficiency motors 240/480 volt, 3 phase

Maxon Ovenpak gas burner, 750,000 Btu maximum

60" width belt w/ 2" tall side plates & 6" pitch mild steel roller chain

BNW Industries is not responsible for

compliance of required local, state,

and national regulatory guidelines

concerning gas, burner, and electrical

features. "As built" electrical

schematic is included. UL approved

electric enclosure available at an

additional cost. All pricing is for

budget purposes. Final pricing will be

submitted after approved engineering

drawings. B.N.W. Industries is NOT

responsible for any and all sales, use,

import or value added taxes.

Cyclone and fan for cleaning exhaust air & exhaust air duct

-$ -$