03

Commissioning

1. Contact the centre control room to authorise a flow-switch test.

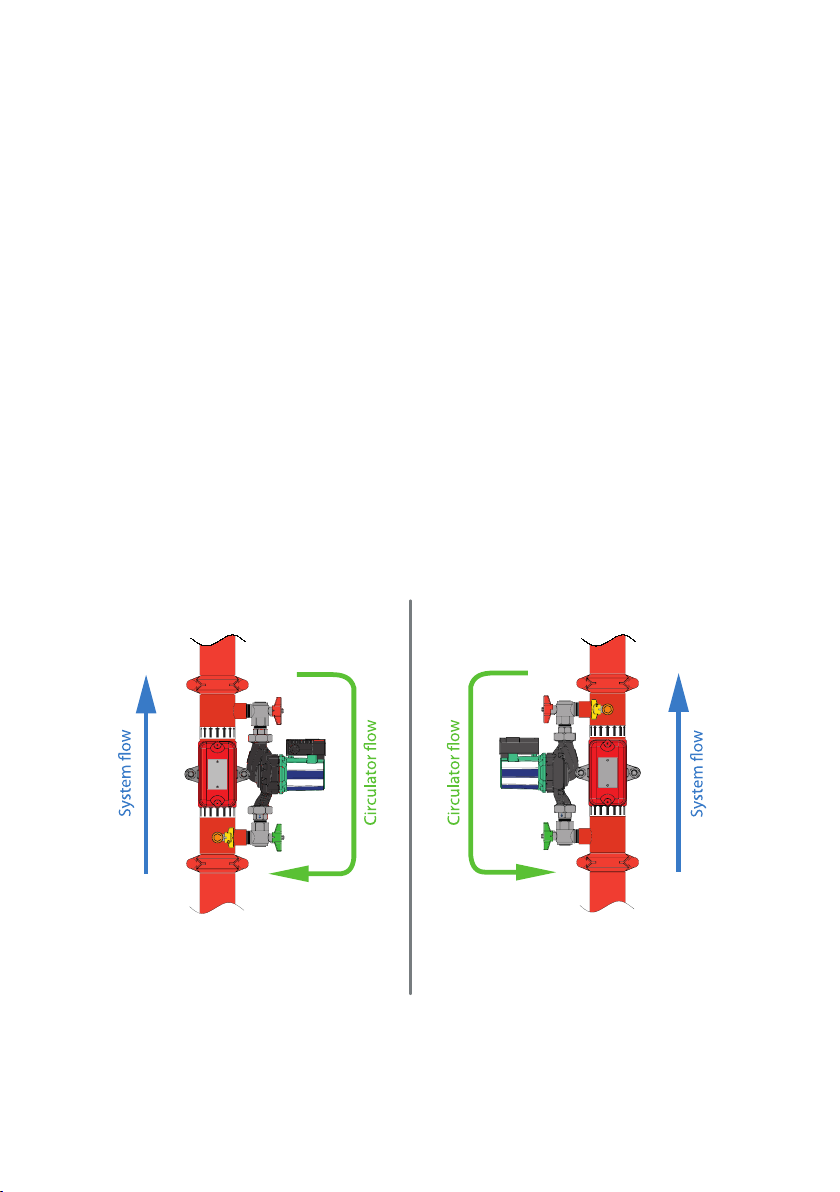

2. Ensure the Zonecheck red and green valves are in the open position (see fig 1).

3. Now remove access plug (air vent) on the end of the Zonecheck pump .

4. Using an appropriate screwdriver turn the shaft clockwise and anti-clockwise to check

the free movement of the shaft and impeller (see fig 2), replace the access plug.

5. Attach hosepipe to yellow vent valve (see fig 1) on the Zonecheck. Now carefully open

the vent valve on the Zonecheck unit to remove the air from the Zonecheck pipework,

allow water to drain to make sure all air is bled from the unit. Then close vent valve and

replace plug.

6. Now connect a hosepipe to the test valve at the furthest point on the zone or use the

yellow test/drain valve provided on the Zonecheck unit (see fig 1).

7. Discharge water through the hose (this is a once only commissioning test).

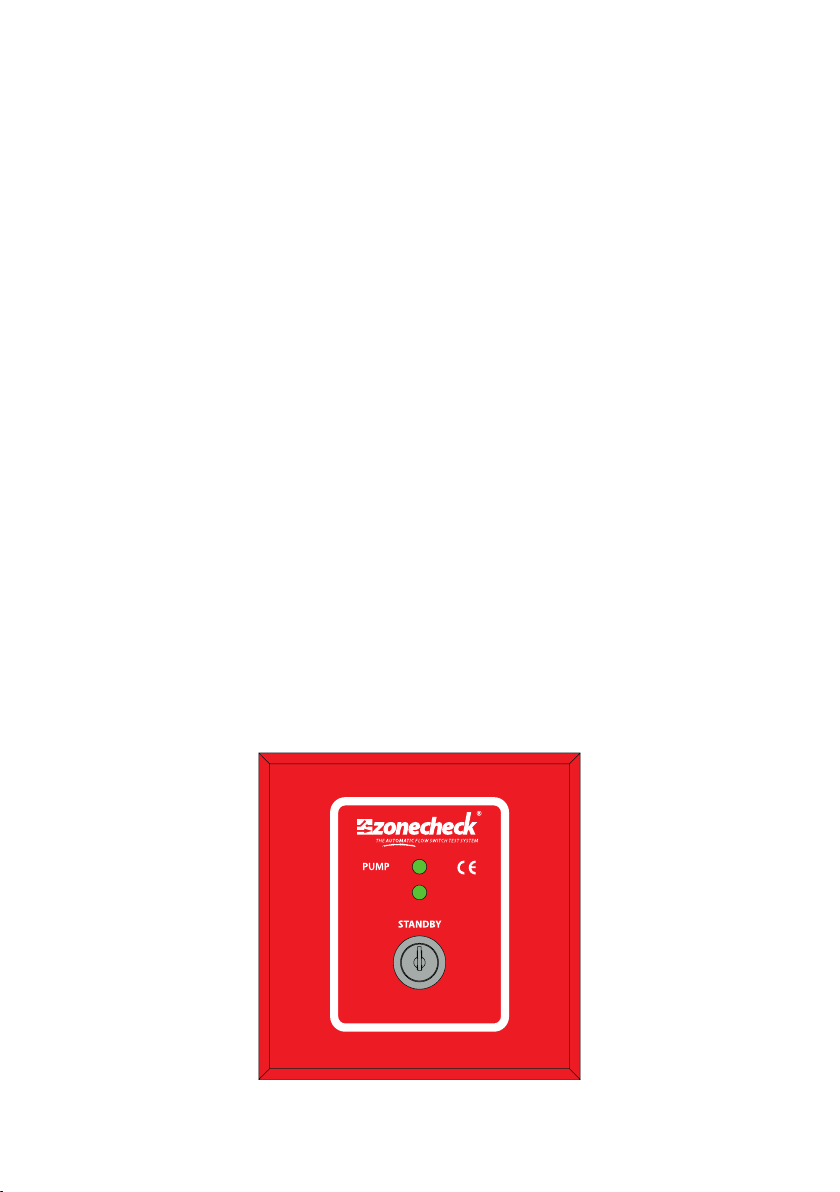

8. Ensure the ‘water flow’ LED is illuminated on the key-switch (make sure the key-switch’s

power supply is on) this could take up to 30 seconds.

9. Now close the test/drain valve as appropriate.

10. Now turn the Zonecheck key-switch to ‘self test’ and check the ‘pump’and ‘water flow’

LEDs are illuminated (this may have a maximum delay of 30 seconds).

11. Confirm with the centre control room that they have received their test signal.

12. Turn the key-switch key to‘standby’ and remove key.

13. Fix operating instructions to wall, preferably next to the key-switch. Also place the

Zonecheck Isolation valve location sticker in a suitable position to let others know

where the unit is.

14. Ensure that the end user is instructed on how to carry out a routine test.

15. Fill in & hand over a completion certificate. Make sure that building management are

made aware when the system is back online.

Test/drain valve

Access plug

Inlet valve

Vent valve

Fig 1 Fig 2

Outlet valve