3DHS Bigfoot 84" User manual

3DHobbyShop.com

Bigfoot 84” Assembly Manual

Thank you for purchasing this 3DHobbyShop ARF RC aircraft. If you have any issues, questions,

concerns or problems during assembly, please contact our tech department at:

[email protected] or 717-814-5316 10am-4pm Eastern Monday – Thursday.

SAFETY in Assembly

During assembly of this aircraft, you will be asked to use sharp knives, hot irons, and hobby adhesives.

Please follow all safety procedures recommended by the manufacturers of the products you use, and

always follow these important guidelines:

ALWAYS protect your eyes when working with adhesives, knives, or tools, especially power tools. Safety

glasses are the best way to protect your eyes.

ALWAYS protect your body, especially your hands and fingers when using adhesives, knives, or tools,

especially power tools. Do not cut toward exposed skin with hobby knives. Do not place hobby knives on

tables or benches where they can roll off or be knocked off.

ALWAYS have a first-aid kit handy when working with adhesives, knives, or tools, especially power tools.

ALWAYS keep hobby equipment and supplies out of the reach of children.

SAFETY in Flying

ALWAYS fly your aircraft in a safe area, away from spectators.

ALWAYS fly your aircraft in a safe manner, within your control.

NEVER fly too close to yourself.

ALWAYS wear eye protection while operating your model aircraft.

ALWAYS keep your hands and body clear of propellers.

ALWAYS observe lipoly battery safety procedures.

ALWAYS handle gasoline in a safe manner.

ALWAYS perform a ground test and range check of your radio system before flying.

REQUIRED ITEMS

CA Glue

Canopy Glue

30 Minute Epoxy Glue (NOT 5-minute Epoxy)

Hobby Knife

Phillips Screwdriver

Set Metric Allen Wrenches

Small Pliers

Wire Cutters

Rubbing Alcohol

Paper Towels

Blue Loctite thread-locking adhesive

Dremel-type rotary tool

Small adjustable wrench or wrench set

IMPORTANT NOTE: 3DHS Recommends ONLY High-Torque, Digital, Metal-gear Servos for this

aircraft. Suitable part numbers include Hitec HS-7955TG,and HS-7954SH. DO NOT attempt to use

nylon-geared servos on this airplane.

THIS AIRCRAFT IS NOT A TOY! IT IS A HIGH PERFORMANCE AEROBATIC AIRCRAFT AND

IMPROPER SETUP AND/OR USE COULD RESULT INJURY OR DEATH.

Assembly Instructions

UNPACK

Unpack your airplane and examine the components. Check for damage of any kind. If you find any

damage, contact 3DHobbyShop and report the damage.

COVERING SEAMS

There are many seams in the covering on this aircraft where one color meets another. We recommend

using a covering iron or trim sealing tool to go over all of the covering seams on your Bigfoot. This will

help to prevent any peeling of the covering. Repeat this periodically.

WRINKLES

Your Bigfoot was packed at the factory without any wrinkles in the covering. You may notice some

wrinkles now; more likely, you will notice a few in a day or two or the first time you take the plane out to

the flying field. These wrinkles are the result of wood shrinkage and/or expansion. Balsa wood changes

size and shape slightly as it is exposed to varying humidity in the air. This is a natural property of balsa

wood. As your airplane adjusts to the weather in your part of the world, wrinkles may appear and

disappear.

Wrinkles may be removed with the gentle application of heat to the covering material on your airplane,

using an iron and/or heat gun. Apply the heat gently: the covering material will shrink as you apply the

heat, and this will remove the wrinkles. BE CAREFUL! Too much heat applied too quickly can damage

the covering, either by causing it to pull away from the wood at seams and corners or even by melting it.

Wrinkles do not affect flight performance.

COVERING MATERIAL

Your Bigfoot is covered with genuine OraCover material. If you need to repair sections, matching

covering is sold at most hobby stores under the “UltraCote” brand.

Using a sharp hobby knife, a small-tip soldering iron, or a hot knife, remove the covering material over the

door and window openings on the fuselage.

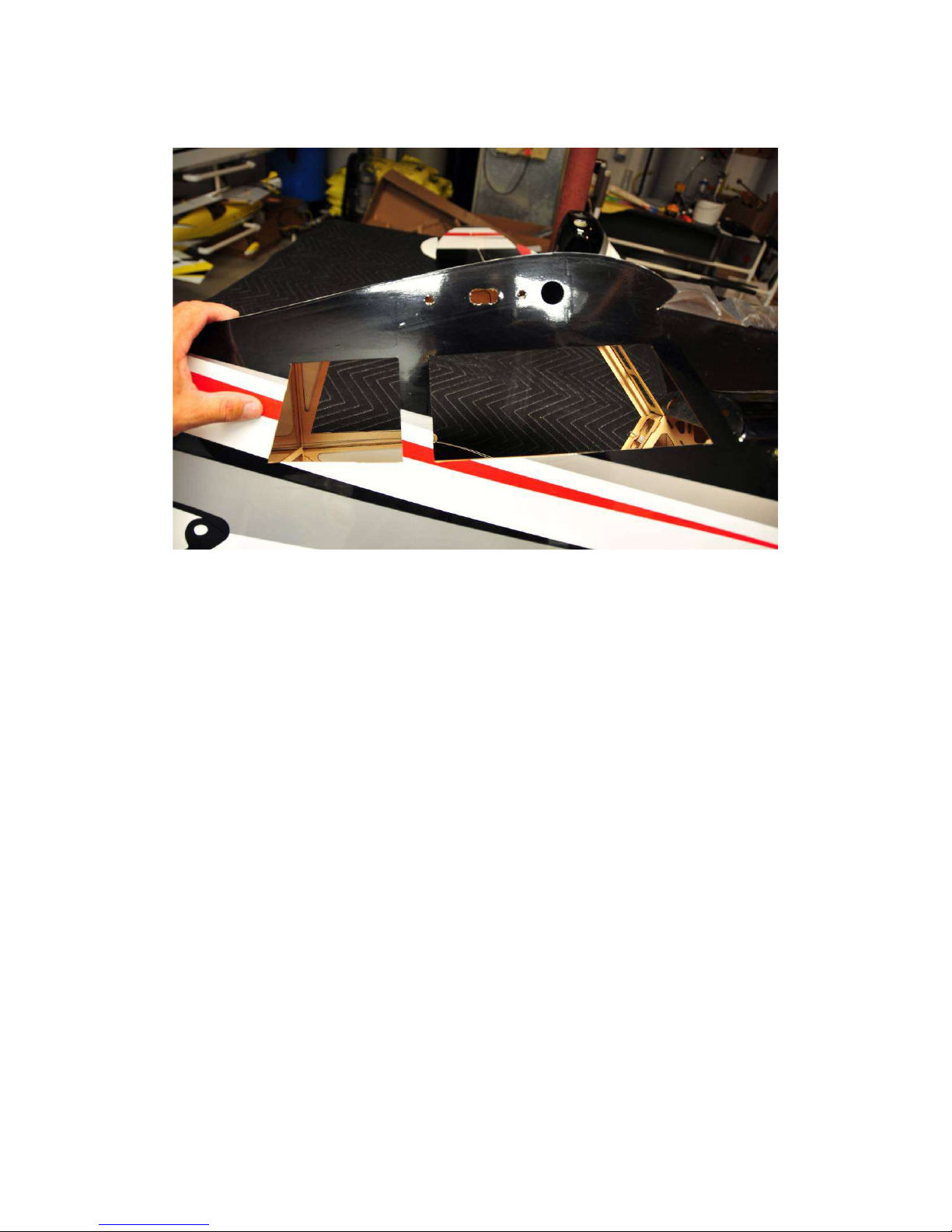

Also remove the covering over the wing spar, wing pin and retainer, and servo wire openings as shown.

Remove the covering over the horizontal stabilizer slot and the rear servo openings as needed. NOTE:

Bigfoot includes two rudder servo mounts, one in the rear on the right side (shown below) and one in the

cabin for pull-pull cable arrangement. If you are using an electric power don't cut the covering away from

the servo opening on the right side of the fuselage, since you will be mounting your rudder servo in the

front. For gas power, mount the rudder servo in the rear.

Test fit the vertical stabilizer into the slot but do not glue it yet. The fit should be snug. If it is too tight,

sand the bottom of the vertical stabilizer slightly.

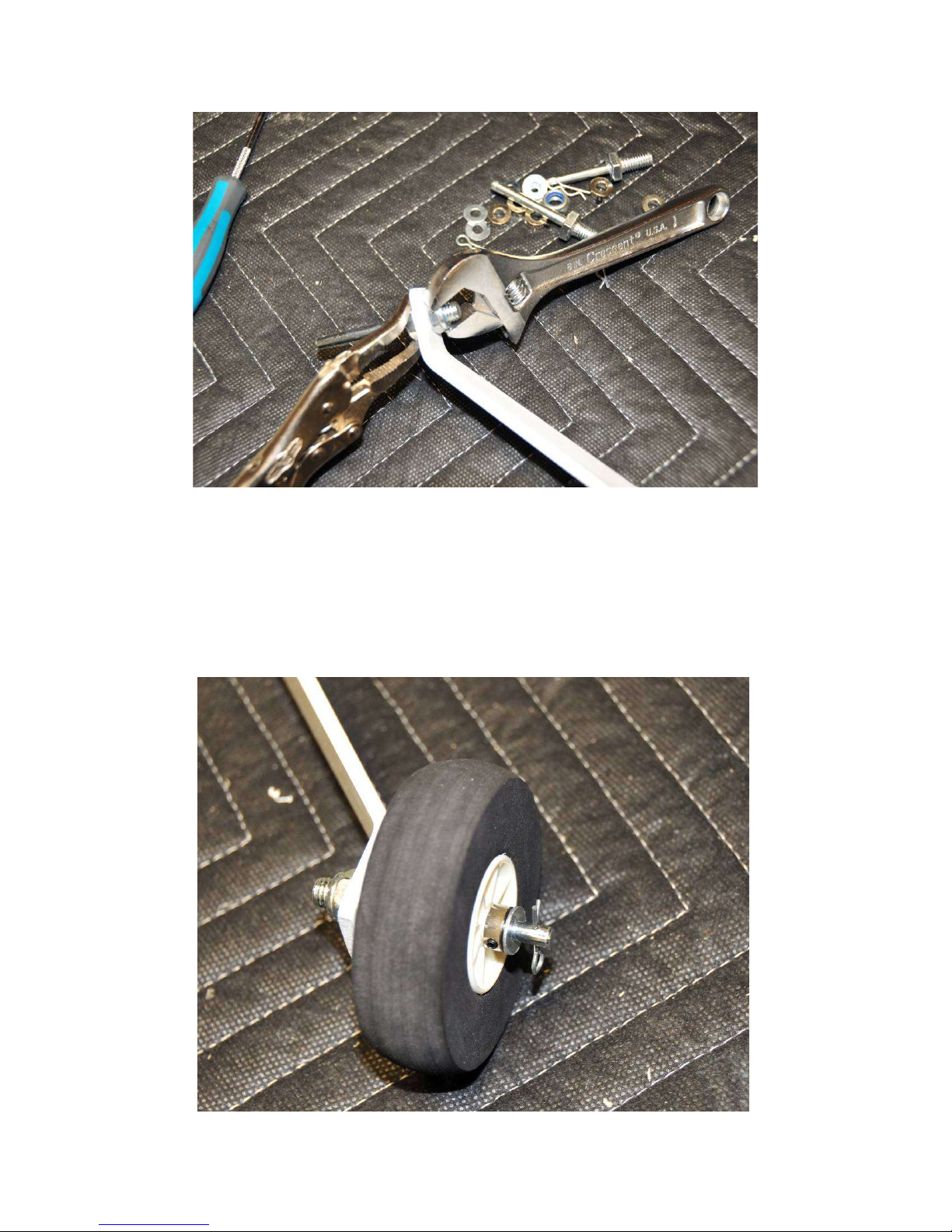

The main axles on the Bigfoot include a cross-drilled hole in the end of the axle for positive retention of

the main wheels with a cross-pin.

Bolt the main axles onto the landing gear as shown.

Your kit includes 3" wheels, which are a very lightweight option. If you wish to use them, install them onto

the axles along with wheels collars and pins as shown.

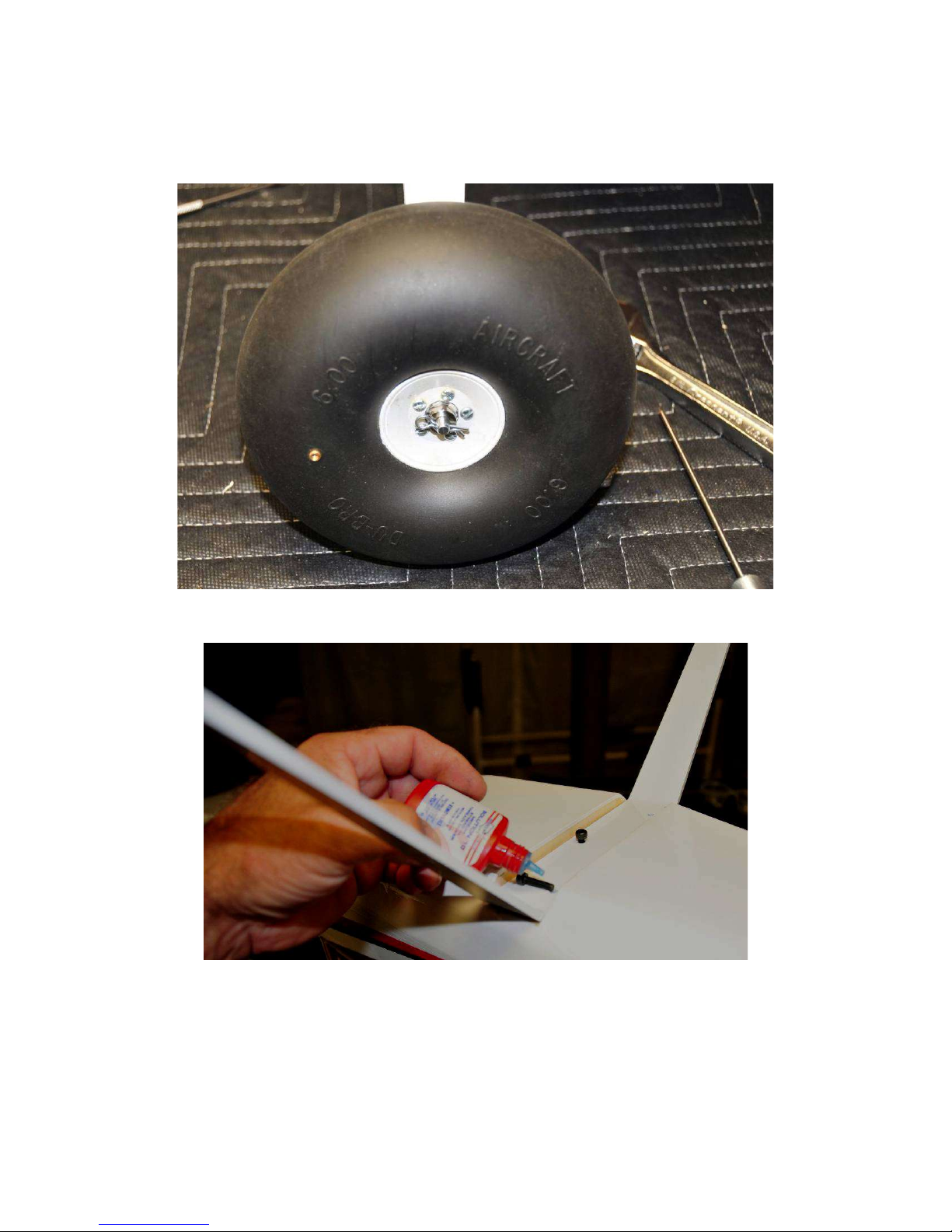

For a more scale look, you can use 6"-8" balloon tires, such as the pictured DuBro 6" balloon tires. Be

certain to use the cross pins as shown for wheel retention.

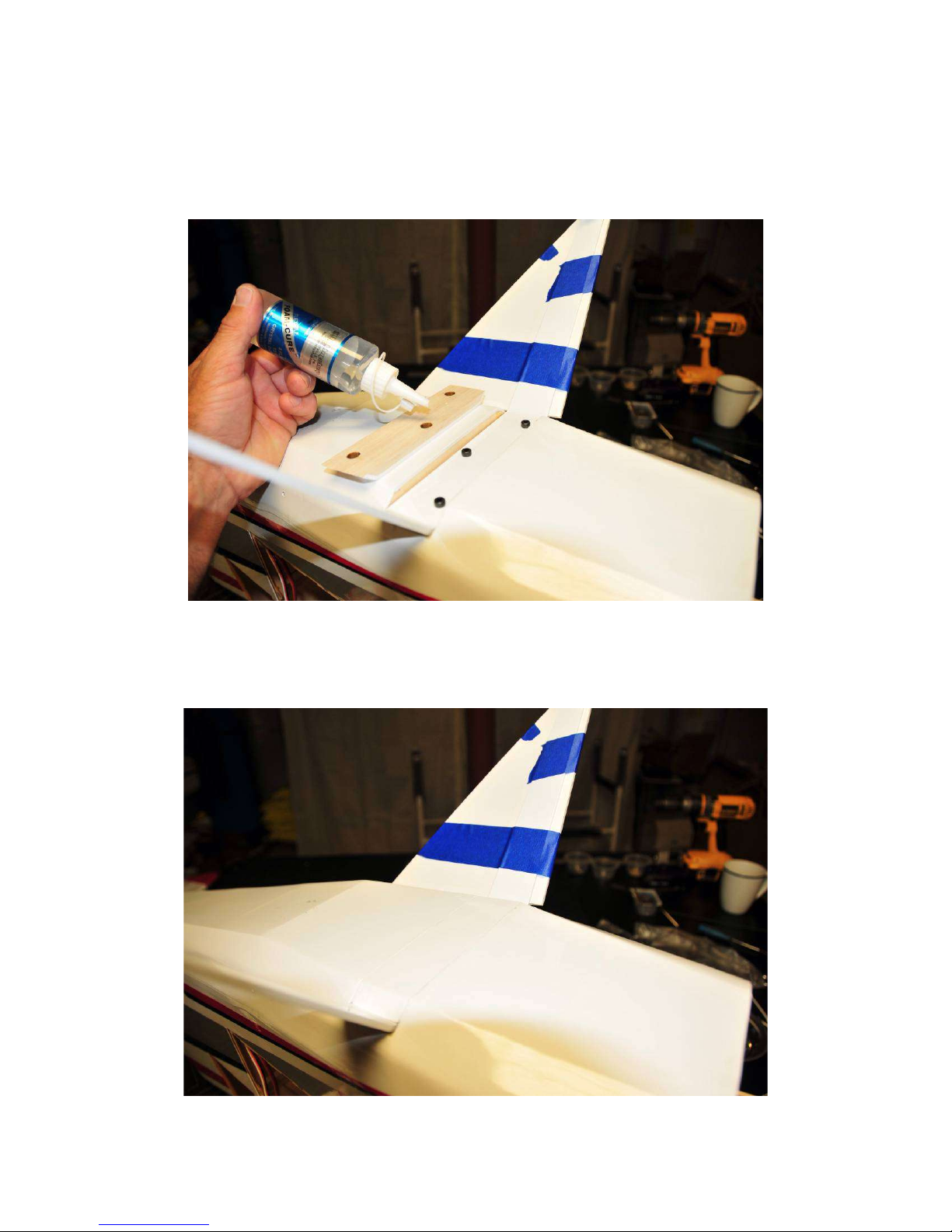

Attach the landing gear to the fuselage as shown, being sure to loctite these screws.

Use rubber cement or epoxy to attach the landing gear fairings.

Use tape to hold the fairings in place while the glue sets.

Use rubber cement or epoxy to install the landing gear cover plate on the bottom of the fuselage as

shown.

Table of contents

Other 3DHS Toy manuals