5

Tips for Success:

1. Before starting assembly, take a few minutes to read the entire instruction manual

to familiarize yourself with the assembly process.

2. Go over all the seams on the aircraft with a covering iron on a medium heat setting.

Also, due to climate changes, wrinkles may develop in the covering. These are easily

removed with a little bit of heat. Use a 100% cotton tee-shirt and your heat gun and

heat the covering while gently rubbing the covering onto the wood with the t-shirt.

Be careful not to use too much heat as the covering may shrink too much and begin

to lift at the edges. Take your time, and a beautiful, paint-like finish is attainable.

3. Apply CA to high stress areas such as servo mounting trays, landing gear mounts,

anti-rotation pins, wing and stab root ribs, and motor box joints etc.

4. By the time your aircraft arrives at your door step, it will have been handled by a lot

of people. Occasionally, there are small dings or imperfections on some of the

surfaces. An effective method to restore these imperfections to original condition is

to use a very fine tipped hypodermic needle and inject a drop of water under the

covering material and into the ding in the wood. Apply heat to the area with a

sealing iron and the imperfection will disappear. Deeper marks may require that

this process be repeated a couple of times to achieve the desired result, but you will

be surprised at how well this technique works.

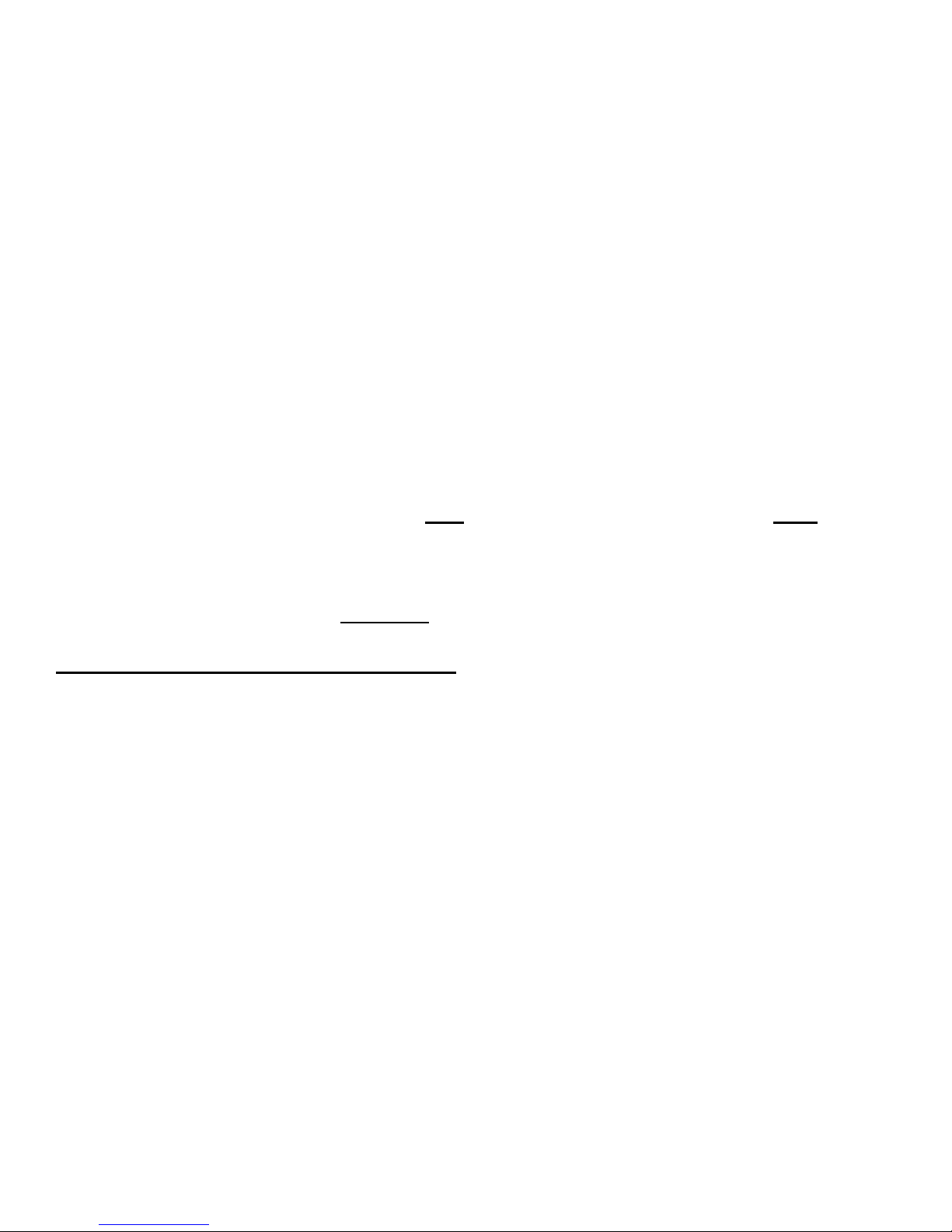

5. Use a high quality epoxy for installing the composite control horns and hinges. We

highly recommend Pacer Z-poxy. We are very pleased with the results and ease of

application and cleanup of this product.

6. Take the time to properly balance and trim your aircraft and set up rates and

exponential values. Your flying experience will be greatly enhanced once your plane

is properly dialed in.

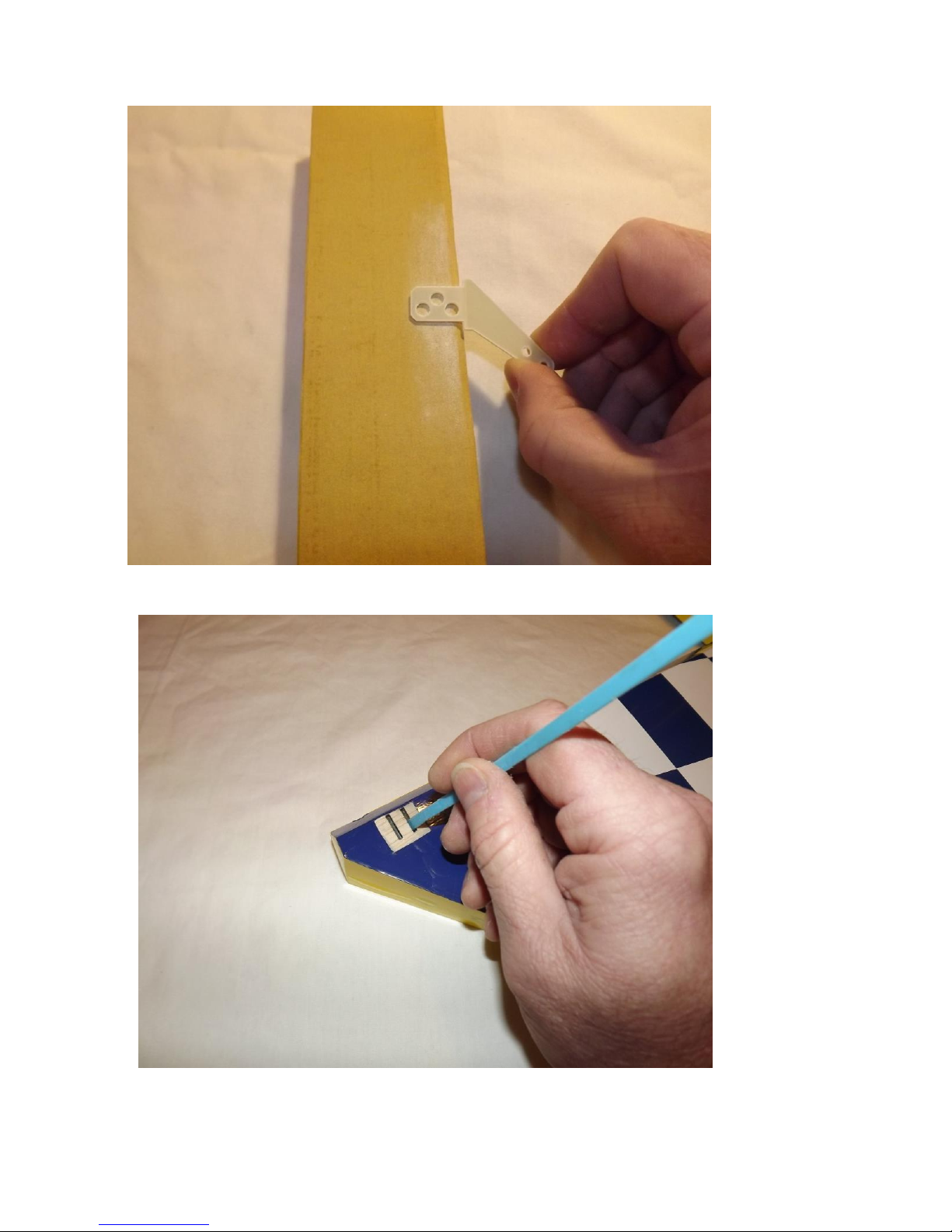

Please Note: Because the assembly process is basically the same for all of the models in

this size, some photos may show parts from another model if it was deemed that these

photos better illustrated the assembly step.